31

VERSION 01/2018

ORDER NUMBER DOC 2340851

Cobra 40-10 / 40-25

7.3 WORK

Ensure that:

commissioning is carried out in accordance with Chapter 6.7.

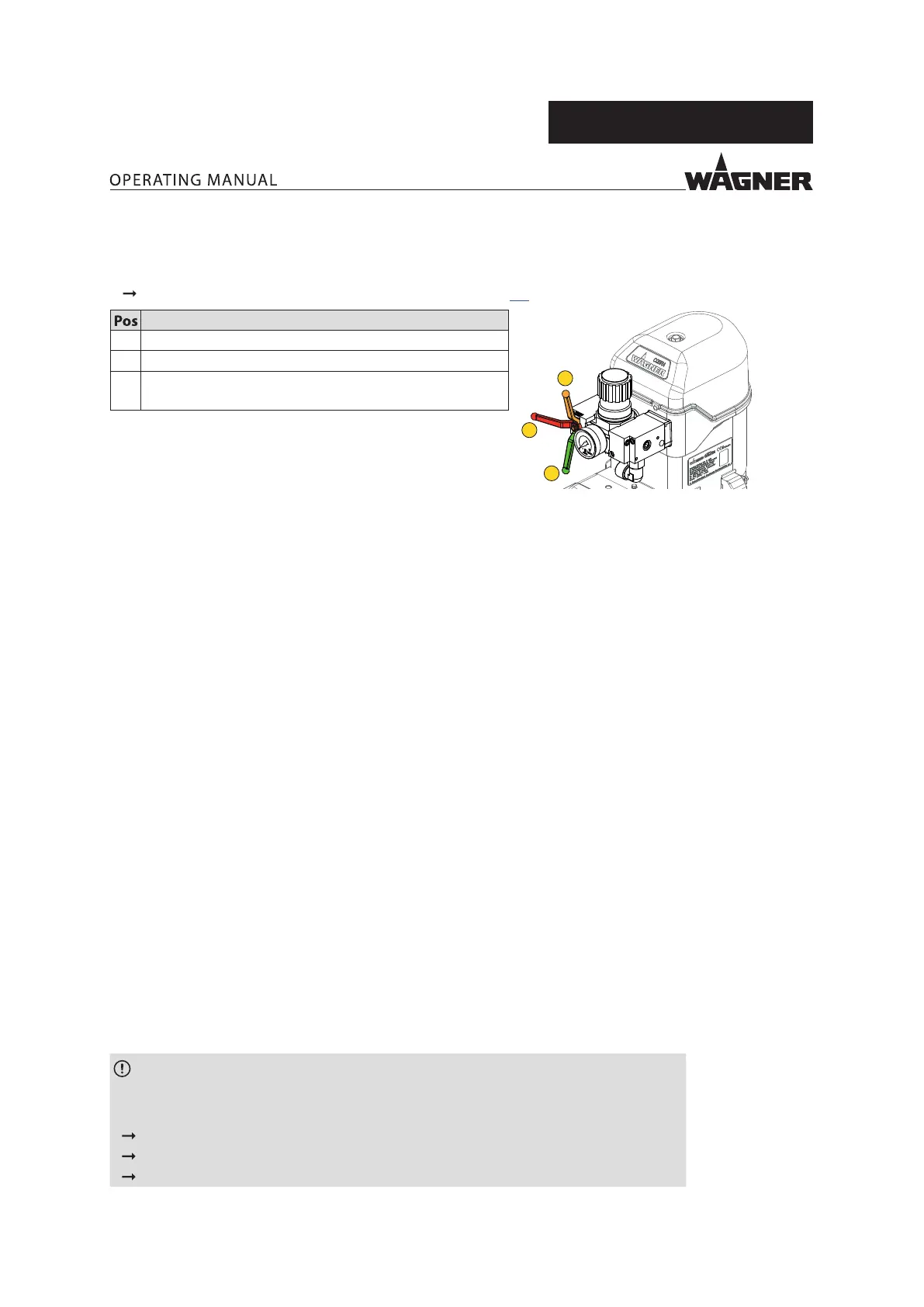

Ball valve position

1 To: working position

2 Closed: the air motor can still be under pressure.

3 Vent: Operating pressure in the air motor is vented

(control pressure is still present).

2

3

1

1. Visual check:

personal safety equipment, grounding and all devices ready to use.

2. Secure spray gun and insert valve into the spray gun.

3. Slowly open the ball valve.

4. Set the required working pressure on the pressure regulator.

5. Optimize the spray pattern as laid down in the spray gun instructions.

6. Start work process.

Note: Depending on the function, the pump may continue running for 1 - 6 DH/min. after

the spray gun is closed.

7.4 PRESSURE RELIEF/WORK INTERRUPTION

The pressure must always be relieved when:

− after the spraying tasks are nished.

− Before servicing the system.

− before carrying out cleaning tasks on the system.

− before moving the system to another location.

− before something needs to be checked on the system.

− before the nozzle is removed from the spray gun.

Process for relieving pressure

1. Close the spray gun.

2. Close ball valve.

3. Vent air motor.

4. Release the system of pressure by opening the spray gun.

5. Close and secure the spray gun.

Note:

Control air pressure is still present.

If the system has been used with 2K products:

NOTICE

Hardened working material in the spraying system when 2K product is processed!

Destruction of pump and injection system.

Follow the manufacturer‘s processing rules, particularly regarding the pot life.

Flush thoroughly before the end of the pot life.

The pot life is decreased by warmth.

Loading...

Loading...