39

VERSION 01/2018

ORDER NUMBER DOC 2340851

Cobra 40-10 / 40-25

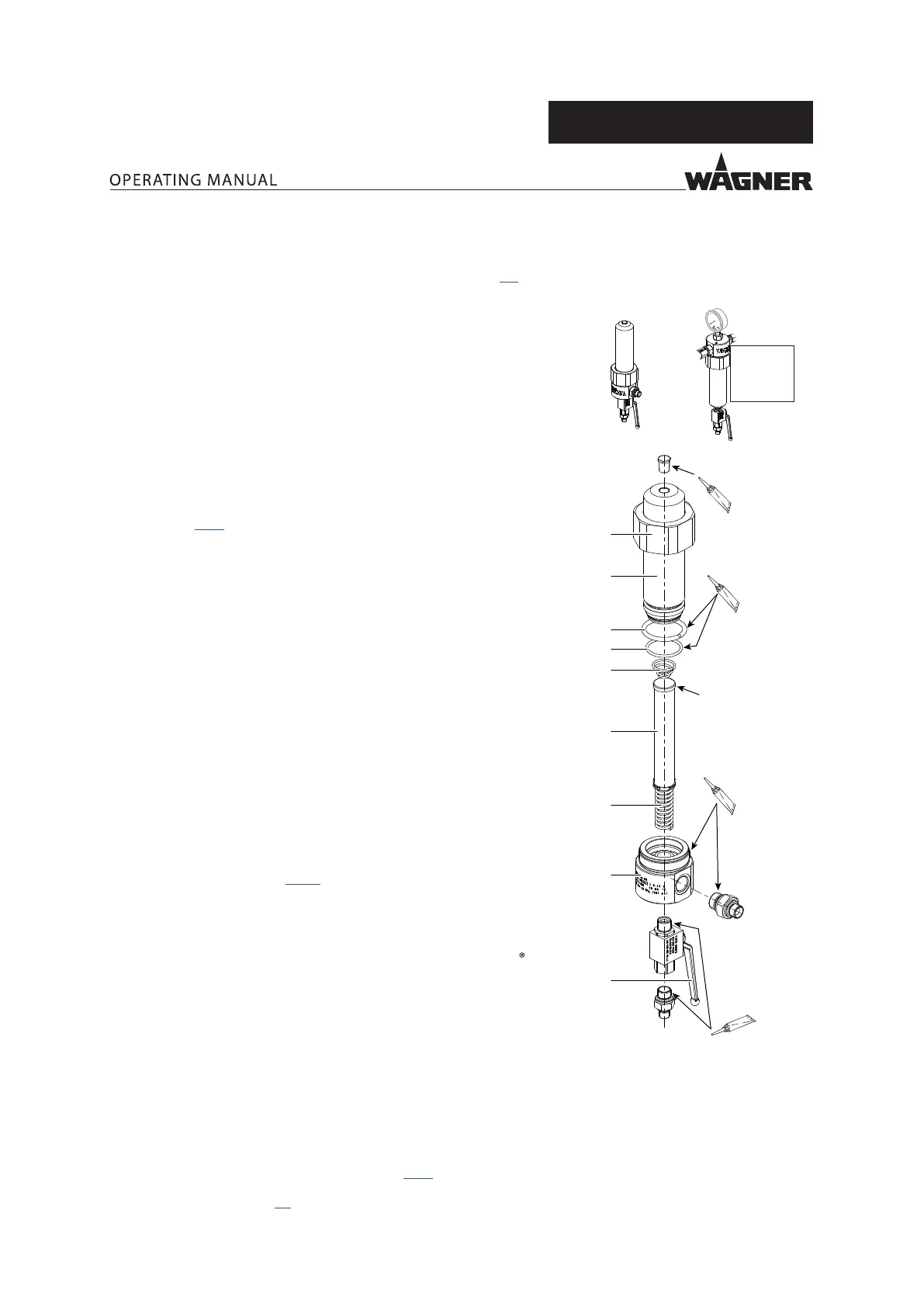

8.2.6.3 HIGHPRESSURE FILTER 530 BAR

1. Flush the pump and HP lter in accordance with Chapter 7.5, and

while doing so:

12

11

10

7

3

5

B_06836

1

21

2

Filter

identication

Mobilux EP2**

Anti-seize paste**

53MPa

530bar

7687psi

Filter installation position

Preferred Turned over

Loctite 542

Loctite 542

– At the preferred lter installation position: Flush via the

return ow valve (1). This produces a large ow. As a result,

the ushing agent also ows through the upper part of the

lter cartridge (11). Pressure regulator approx. 0.15MPa;

1.5bar; 22psi.

– At the reversed lter installation position: Flush using the

gun. This is required in the case of a reversed installation

position so that the ushing agent ows through the lter

cartridge (11). Maximize the ow (remove the nozzle, open

the dosing valve if necessary).

2. Empty the pump in a controlled manner in accordance with

Chapter 8.2.4.

3. Place the grounded collection tank under the High-pressure lter.

4. Open ball valve (1).

5. Loosen union nut (3) with a size 70 wrench.

6. Unscrew the union nut (3) and lift slightly so that it does not get

dirty in the next step.

7. Remove the lter housing (2) with the union nut (3). The cone

spring (12) remains in the lter housing (2). If the O-ring (5) is not

damaged, it remains on the lter housing (2).

8. Remove the lter cartridge (11) and lter support (10) from the

lter housing (2).

9. Clean all parts:

– Place the lter cartridge (11) and lter support (10) in solvent.

Clean using brush.

– Fill the lter housing (2) approx. 1/3 full with solvent, secure

wearing a glove and shake well.

– Clean the distribution housing (7) using a brush.

10. If necessary, replace the O-ring (5) and/or lter cartridge (11).

Order No., see Chapter 14.12.

11. Assemble all parts in reverse order. While doing so:

– Coat the thread of the distribution housing (7) with anti-seize

paste**.

– Coat the O-ring (5) and pressure ring (21) with Mobilux

EP2**.

– Observe the installation position of the lter cartridge (11):

Push the closed end with the lter identication ahead into

the lter housing (2).

– Make sure that the cone spring (12) is in the lter housing

(note the installation position). Press on the cone spring after

inserting the lter cartridge (11) and lter support (10); the

spring action must be noticeable.

– Tighten the union nut (3) by hand.

12. Close ball valve (1).

13. Fill the pump in accordance with Chapter 8.2.5.

** Order No., see Chapter 13.

Loading...

Loading...