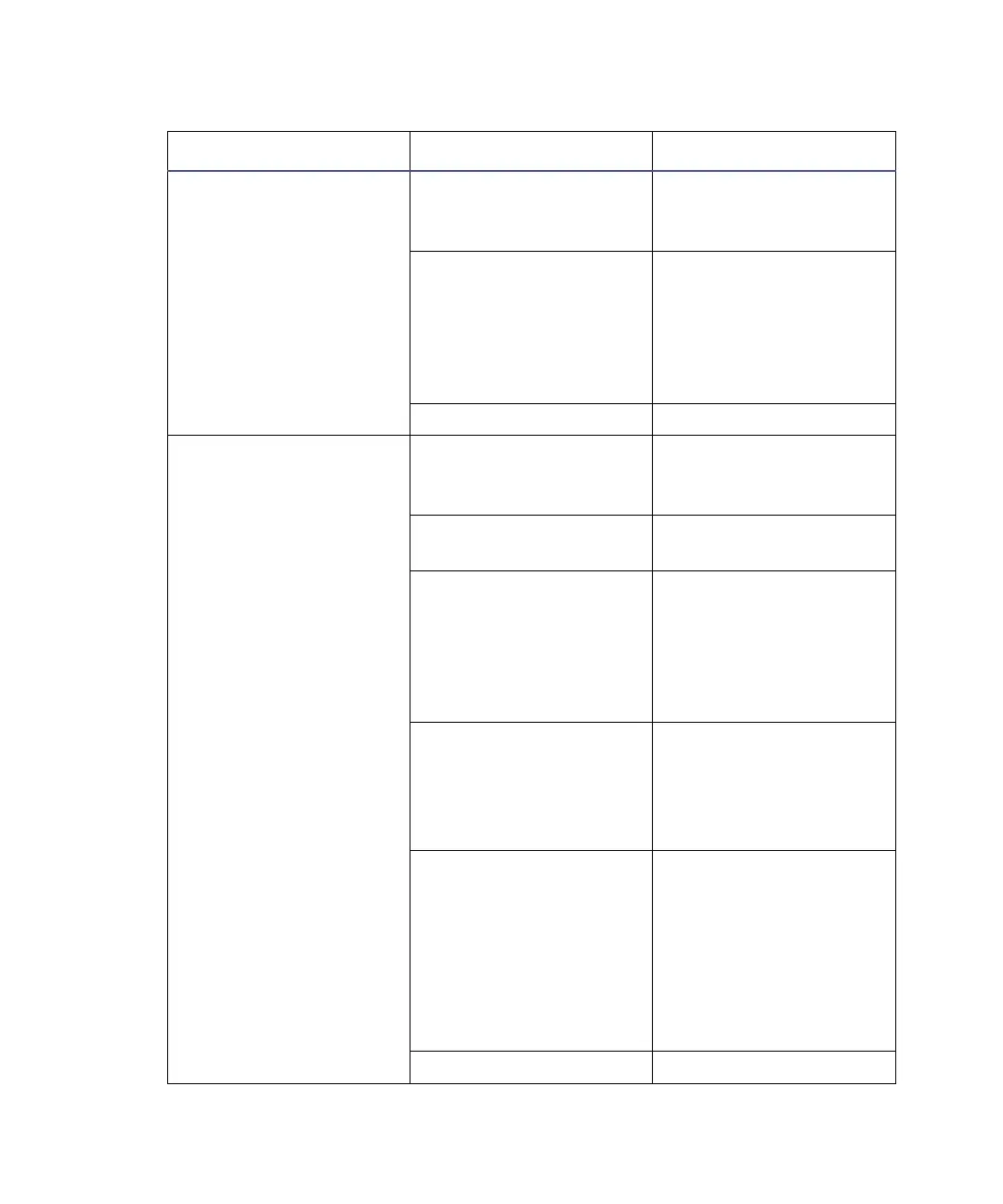

3-28 Troubleshooting, Testing, and Maintenance

Reproducibility errors Syringe contains an air

bubble (usually seen at

the top of the syringe)

Remove bubble.

Leaks at the fluid

tubing connections

Check for leakage at the

connections with the

corner of a tissue, and

tighten connection

slightly if the tissue is

moistened.

Seal pack failure Replace seal pack.

Compression check

failed

Syringe contains air

bubble (usually seen at

the top of the syringe)

Remove bubble.

Mobile phase not

properly degassed

Sparge mobile phase.

Leaks at the fluid

tubing connections

Check for leakage at the

connections with the

corner of a tissue, and

tighten connection

slightly if the tissue is

moistened.

High pressure limit on

PUMP SETUP screen

must be at least two

times compression

pressure

Change pressure limit

on the PUMP SETUP

page; change pump flow

to adjust pressure.

Parameters used for

Compression Check

unacceptable for solvent

Repeat the test using

default parameters on

Purge and

COMPressION test

screen. If the test fails

again, perform an

autocalibration and

repeat the test.

Seal pack failure Replace seal pack.

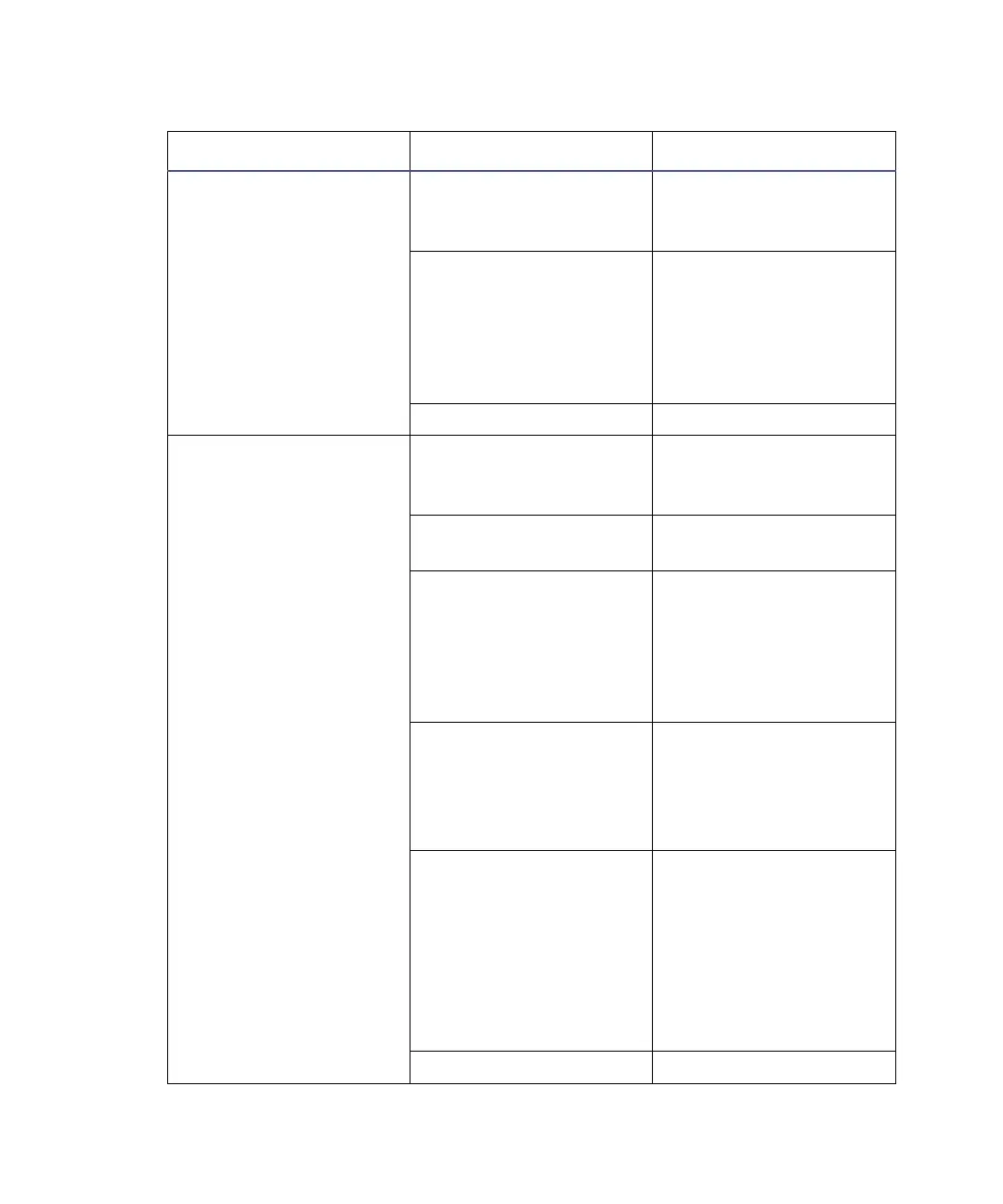

Autoinjector troubleshooting (Continued)

Symptom Possible cause Corrective action

Loading...

Loading...