Waters Prep series 1-5

• Space for three analytical or semi-prep columns

• One 2-inch preparative column, and/or an M-1000 compression chamber

for PrepPak

®

cartridges.

Rheodyne 7725i injector – For small scale injections, incorporates a 100-µL

fixed sample loop, though you can install loops whose injection volumes vary.

Optional loops, available from Waters, handle fixed volumes from 5 to 200-µL.

Rheodyne 3725i injector – For large-scale injections, incorporates a 20-mL

fixed sample loop, though you can install loops of varying injection volumes.

Optional loops, available from Waters, handle fixed volumes from 2 to 20 mL.

Purge valve – Lets you divert pump output to waste (e.g., when purging the

system) or through the injector, columns, etc.

Scale switching valve – Lets you choose large- or small-scale tubing

systems. In the small-scale system, the injector is in a flow path plumbed with

0.009-inch ID tubing. In the large-scale system, solvent flows from the pump

to the large-scale injector through 0.040-inch ID tubing.

Inlet and outlet ports – Accepts pump outflow. The inlet port receives

solvent for both small- and large-scale flow paths, which flow to separate

outlet ports. The flow from these outlets goes to the detector flow cell.

Purge outlet port – Flow goes from the inlet port to this outlet port when

you set the purge valve to Purge.

Waters Prep series modules

This section addresses these Prep Series major modules:

• Fluid handling unit

• PrepLC controller

• Rheodyne 3725i injector (PrepLC and Delta-Prep systems)

• Rheodyne 7725i injector (Delta-Prep system only; optional for PrepLC

system)

• Column rack (Delta-Prep system only)

• Injector panel (PrepLC system only)

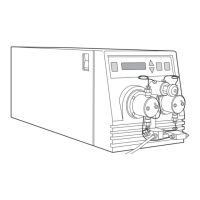

Fluid handling unit

The figure below shows the internal workings of the fluid handling unit, which

delivers solvents from their reservoirs to the injector.

Loading...

Loading...