Connecting a helium tank to the fluid handling unit 2-31

Sparging

Sparging minimizes dissolved gases in the solvent. This decreases the

potential for degassing when different mobile phases mix in the gradient

proportioning valve. The helium flow through the system is as follows:

• The helium is introduced into the solvent through a diffuser, which

disperses the gas into small bubbles. The bubbles increase sparge

efficacy by increasing the surface area of solvent exposed to helium.

• A reduction in total dissolved gas occurs as the pure helium equilibrates

at the gas-liquid interface.

• The displaced gases are carried to the surface and then expelled through

the reservoir vent.

Tip: For more information on this process, see Appendix D.

Connecting compression fittings

Use 1/16-inch stainless steel tubing with an ID of at least 0.020 inches

(preferably 0.040-inch ID) to connect the fluid handling unit with the helium

supply. Connect each end of the tubing with compression fittings. See “Liquid

line connections” on page 2-21 for details.

Connecting the helium supply

Shutoff valve assembly

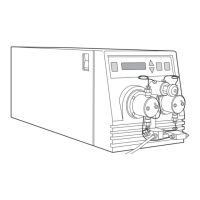

Assemble the shutoff valve and sparge tubing as shown in the figure below.

Use these Startup Kit components:

• 0.062-inch × 0.040-inch ID stainless steel tubing

• Compression screws

• Ferrules

Loading...

Loading...