Setting up the plunger wash 2-35

4. Put the inlet tube back into the wash solvent reservoir.

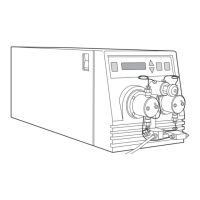

Connecting to the injection panel (PrepLC system)

Tip: Refer to the figure “Injector panel (PrepLC system)” on page 1-13 when

following the procedure in this section.

Connecting to the purge valve and Rheodyne 3725i injector

The pump outlet connects to the injection panel with 0.020-inch ID tubing.

The PrepLC system uses the same size tubing to connect to the injector panel.

The Rheodyne injector, designed for large-scale operation, has flow passages

of 1.0-mm ID.

To connect the pump outlet to the injection panel:

1. Cut a length of tubing to extend from the pump outlet to the unused

fitting on the injector panel’s purge valve, or that goes directly to the

column inlet.

2. Install compression fittings on the pump end of the tubing as described

in “Liquid line connections” on page 2-21.

3. Tighten the fitting at the pump outlet.

4. Remove the unused nut and ferrule from the purge valve, and install

them on the other end of the pump outlet tubing. Attach the tubing to

the purge valve and tighten (see the figure “Pump outlet connection to

the column rack inlet (Delta-Prep system)” on page 2-39).

Put a waste beaker under the injector’s waste tubing (see the figure “Pump

outlet connection to the purge valve (PrepLC system)” on page 2-36).

Loading...

Loading...