Troubleshooting 3-3

3. Evaluate parameters in this sequence to rule out simple problem causes:

a. System pressure

b. Baseline

c. Peak retention time

d. Peak resolution

e. Qualitative and quantitative chromatography results

Isolate the parameter whose behavior varies from its usual

performance during normal system operation.

4. Run the performance test for a specific module to quickly determine

whether a problem exists.

5. Use the troubleshooting flowcharts in “Troubleshooting flowcharts” on

page 3-5 to deduce a symptom’s possible cause.

6. See the table below to determine corrective actions.

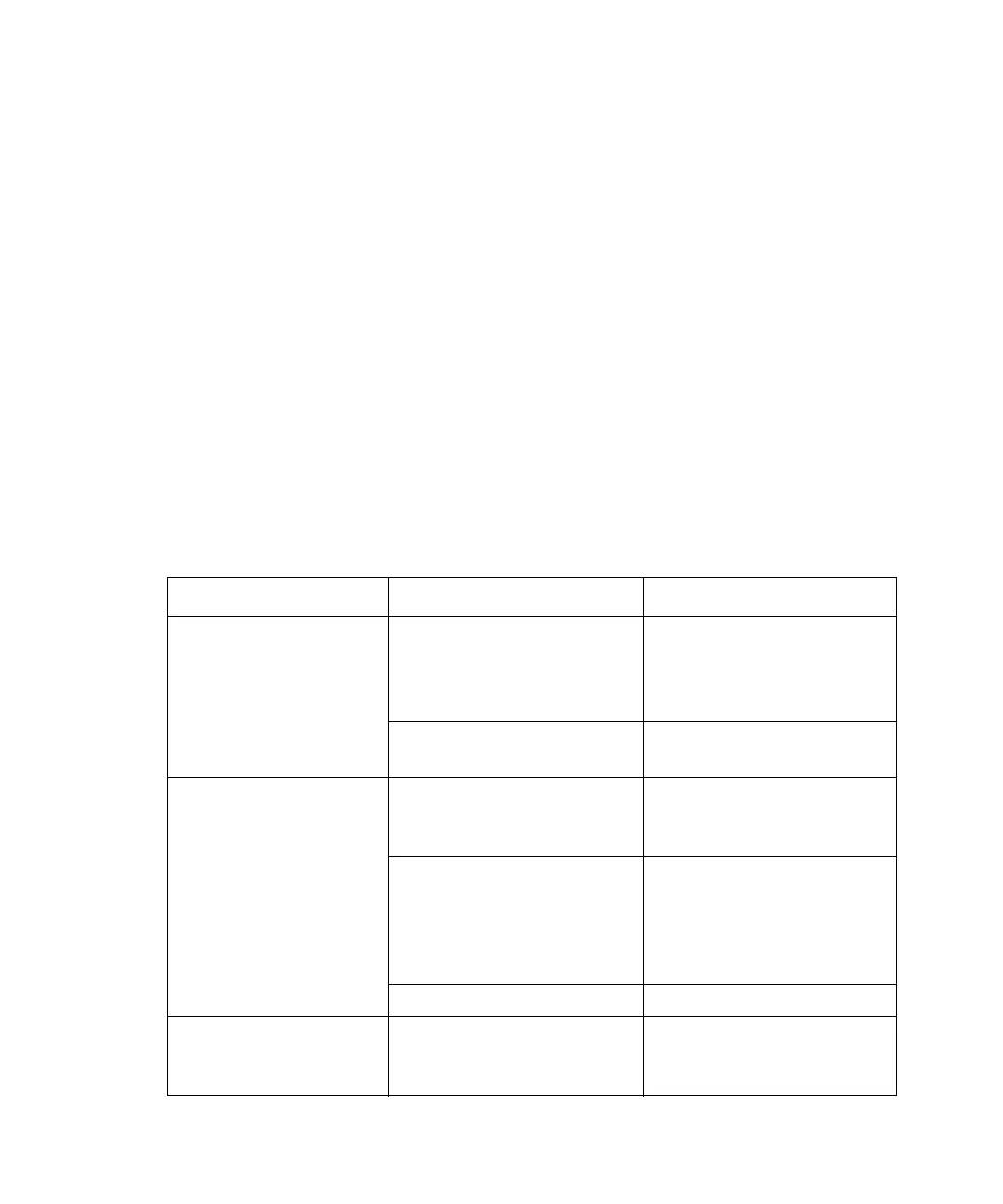

General PrepLC troubleshooting

Symptom Possible cause Corrective action

Grinding or

shuddering noise

from pump - high

pressure shutdown

not exceeded

Blockage in system

before transducer

Clean pump head outlet

tubing, outlet check

valve and tubing to

transducer.

Mechanical problem Call Waters Technical

Service.

Pump shutting down,

high pressure limit

exceeded

High flow rate during

injection valve actuation

caused pressure spike

Decrease flow rate

during injection.

Blockage in system after

transducer

Remove components

between pump and end

of system to determine

source of blockage.

Eliminate blockage.

Column plugged Clean or replace column.

Pump shutting down,

low pressure limit

exceeded

Leaks, empty reservoirs,

or bubbles in the pump

head

Eliminate leaks, fill

reservoirs, prime pump.

Loading...

Loading...