2-30 Installing the System

2. Connect the other end of the vent tube to an eluent filter (see the figure

“Solvent reservoir filter and diffuser placement” on page 2-28).

3. Place the filter end of the vent tube in a fume hood.

4. Insert the solvent reservoir cap into the top of the reservoir.

5. Repeat steps 1 to 4 for each solvent reservoir.

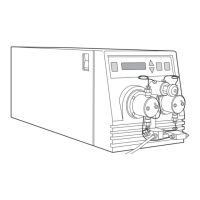

Connecting a helium tank to the fluid handling unit

This section describes how to connect a helium tank to the fluid handling unit.

Tip: The system does not include the high-pressure gas regulator required to

connect the sparge inlet to a helium tank. The Startup Kit includes the shutoff

valve, tubing, and other fittings for connecting the sparge inlet to a 50 to 90

psi helium supply.

Helium sparging reduces the total dissolved gas in the solvent reservoirs and

maintains that condition during operation. Use an ultra-pure carrier (UPC)

grade of helium to prevent solvent contamination.

Helium specifications

Regulate the supply source to between 50 and 90 psi (3.4 and 6.1 atm) before

connecting to the sparge inlet connection (see the figure “Sparge gas inlet

connection” on page 2-33).

The required specifications for UPC-grade helium are as follows:

• Less than 5.0 Mppm (molar parts per million) nitrogen

• Less than 5.0 Mppm oxygen

• Less than 1.0 Mppm total water

• Less than 0.5 Mppm total hydrocarbon

Caution: Using an inferior grade of helium can void your system’s

warranty.

Loading...

Loading...