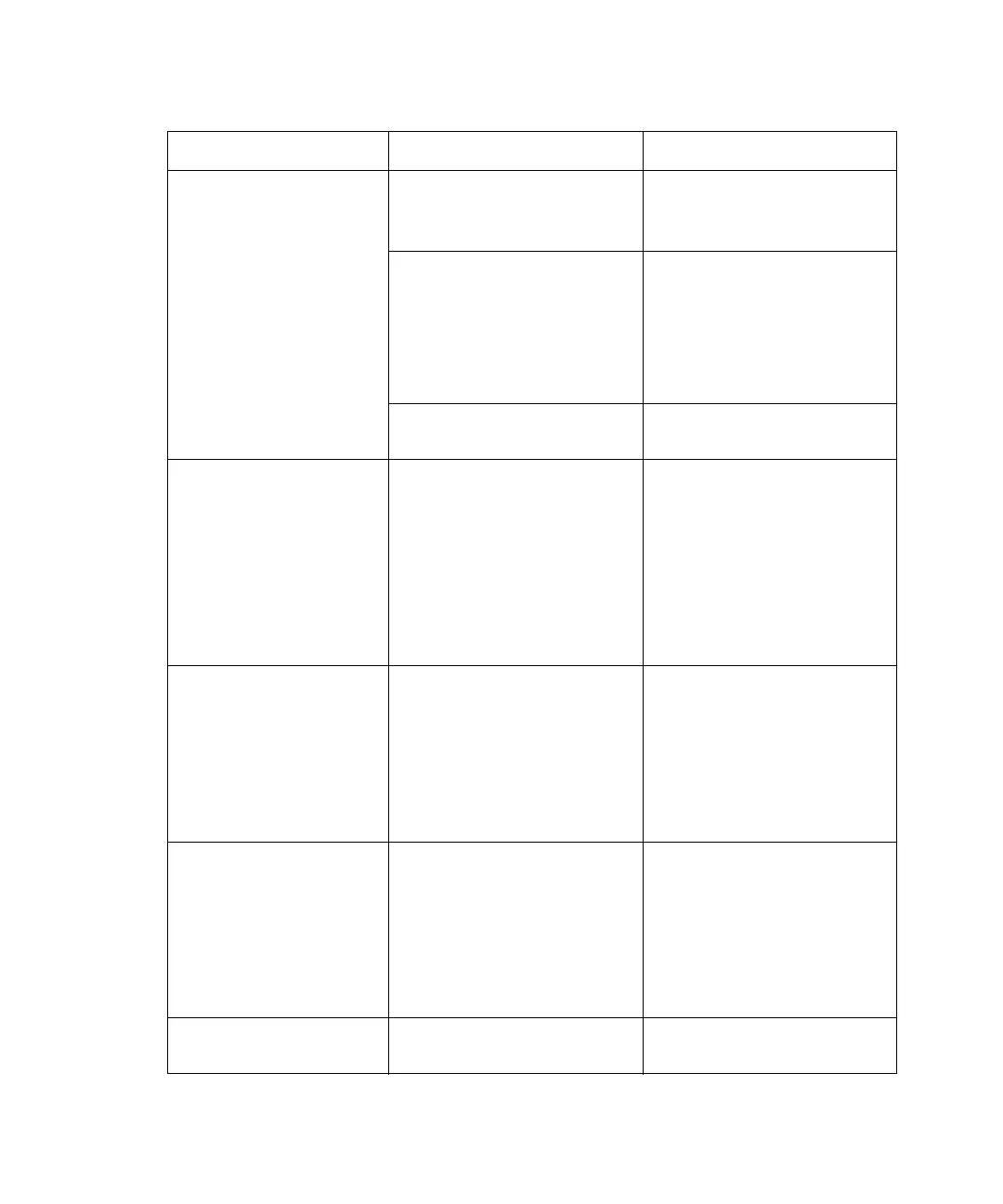

3-4 Troubleshooting, Testing, and Maintenance

Pump cavitating Solvent reservoirs

positioned below solvent

proportioning valve

Place solvents on bench

beside fluid handling

unit.

Leak in tubing

connections or loose

fittings prior to inlet

check valve, causing

aspiration of air (fluid

leak may not be visible)

Eliminate leak, tighten

fittings, replace ferrules.

Solvent inlet filter

restricting flow

Clean or replace filters.

RI detector leaking

internally or from

purge port

Cell damaged –

maximum flow rate or

pressure of RI cell

exceeded

Do not exceed 5 mL/min

(2414, 2410, and 410

Detectors). Do not exceed

100 psi for any Waters RI

detector.

Replace detector flow cell

if necessary (see detector

operator’s guide).

Peak retention times

halved

Incorrect pump head

volume entered on

PUMP

CONFIGURATION

screen

For PrepLC operation

with 1000-µL pump

heads, enter 1000 for

pump head volume on

the PUMP

CONFIGURATION

screen.

Unable to enter a

flow rate above

150 mL/min

Incorrect pump head

volume entered on

PUMP

CONFIGURATION

screen

For operation with

1000-µL pump heads,

enter 1000 for pump

head volume on the

PUMP

CONFIGURATION

screen.

Pulsing flow from

waste line

Dirty check valve(s) Clean check valve(s).

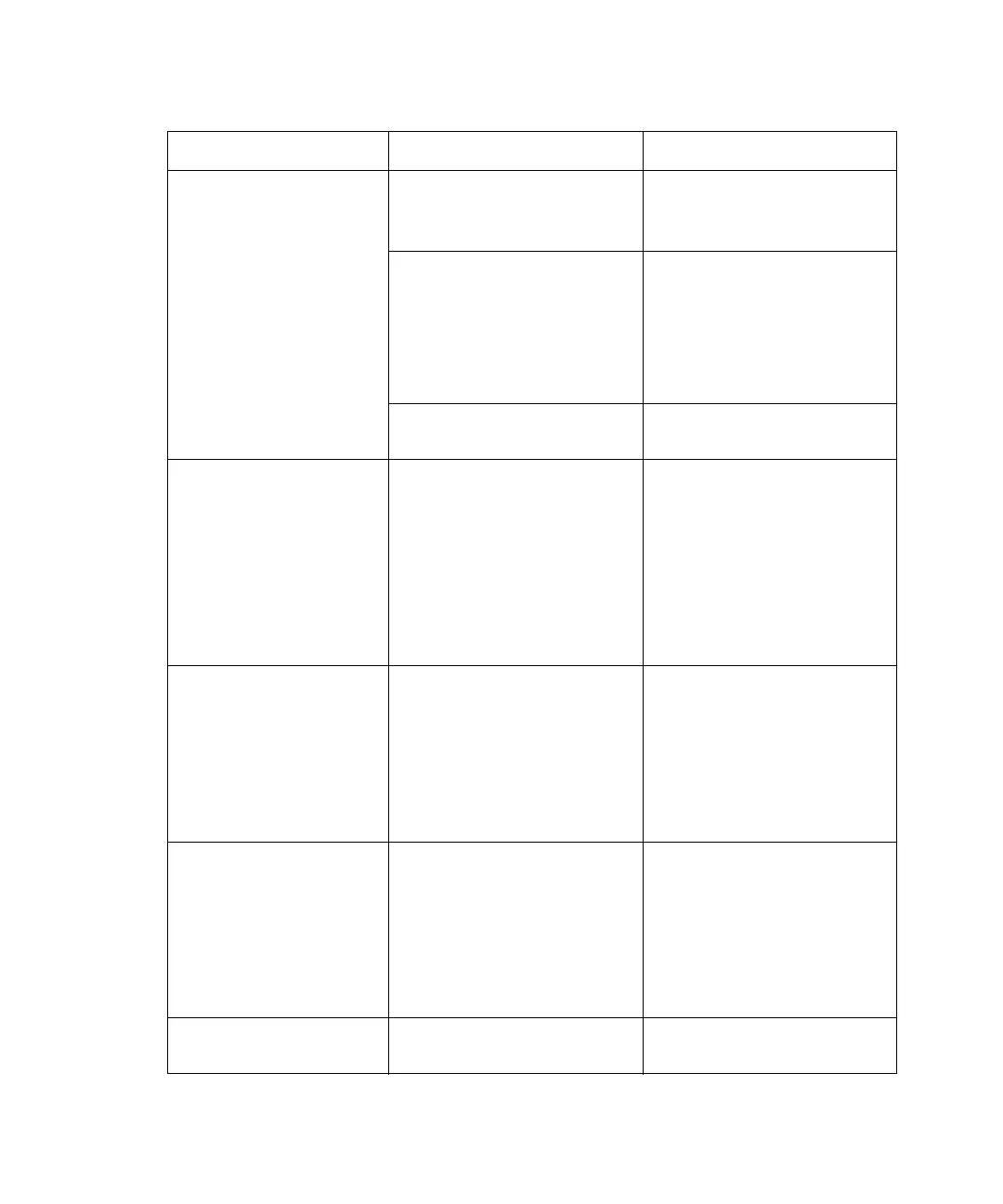

General PrepLC troubleshooting (Continued)

Symptom Possible cause Corrective action

Loading...

Loading...