Maintenance procedures 3-55

4. Place the ball in the seat.

5. Lower the sleeve around the ball, placing it on the seat.

6. Place the retainer over the ball and seat assembly. Center it within the

pump head.

7. Place the seal guide into the outlet check valve housing. Press it into

place.

8. Place the outlet check valve housing over the retainer.

9. Hand tighten the assembly.

10. Tighten the outlet check valve, and attach the tubing.

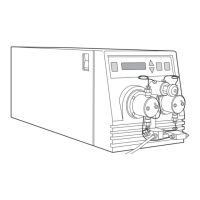

To disassemble and reassemble dual outlet check valves:

Pumps fitted with 1000-µL heads require a dual outlet check valve

, shown in

exploded view in the figure “Dual check valve assembly” on page 3-56.

1. If the flushing procedure in “Cleaning check valves” on page 3-51 does

not sufficiently clean the dual outlet check valve, disassemble the check

valve assembly as described in “Disassembling inlet check valves” on

page 3-51 and “To disassemble outlet check valves:” on page 3-53.

2. Check the valve parts for damage. If none is apparent, put the parts in

methanol, in an ultrasonic bath, for 10 minutes. If a part is damaged,

replace it as necessary.

3. Reassemble the check valve assembly as described in “To reassemble

inlet check valves:” on page 3-53 and “To reassemble outlet check

valves:” on page 3-54.

Loading...

Loading...