How it works

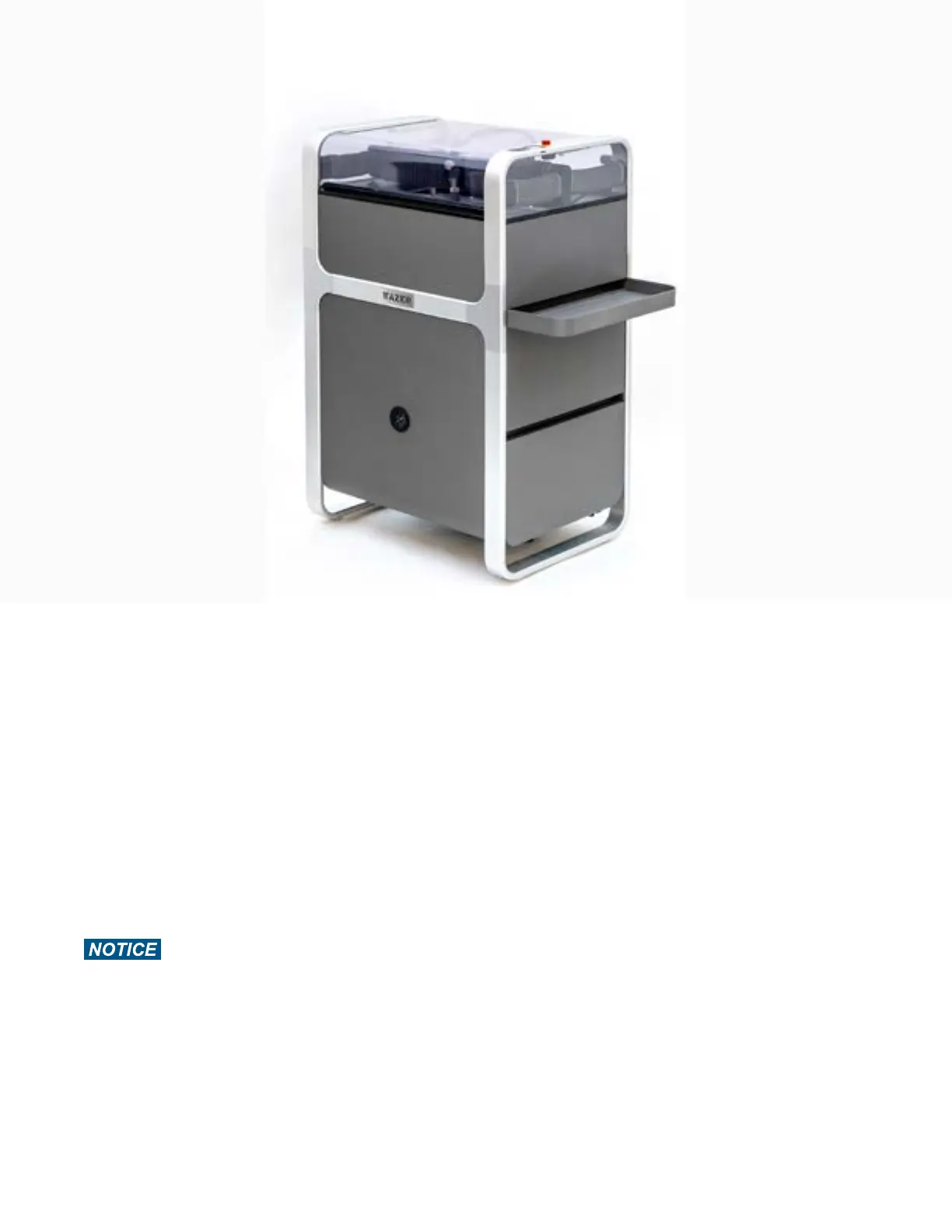

WAZER Pro combines high-pressure waterjet technology with several electro-mechanical systems to

bring you an all-in-one cutting solution.

The Pump section pressurizes water that is then routed to Main Unit section and expelled through a

small orifice, where it accelerates to a very high velocity. At this point the WAZER Pro introduces Abrasive

to the Jet to create a slurry of water and abrasive. This high-pressure stream of abrasive slurry performs

the cutting in a waterjet system. By controlling where this stream is ejected, WAZER Pro allows you to cut

your design with digital precision.

A Tank below the cut bed catches the slurry after it does its cutting work. A collection system allows

WAZER Pro to separate the slurry back into water and Used Abrasive. The water is expelled out of

WAZER Pro, while the used abrasive is separately collected inside of the machine for later removal.

An on-board Control Box runs the logic behind WAZER Pro. This Control Box is connected to all the

input and output components of WAZER, allowing the machine to operate all the individual systems in

harmony. Additionally, it allows the user to interact with WAZER Pro through an onboard Control Panel.

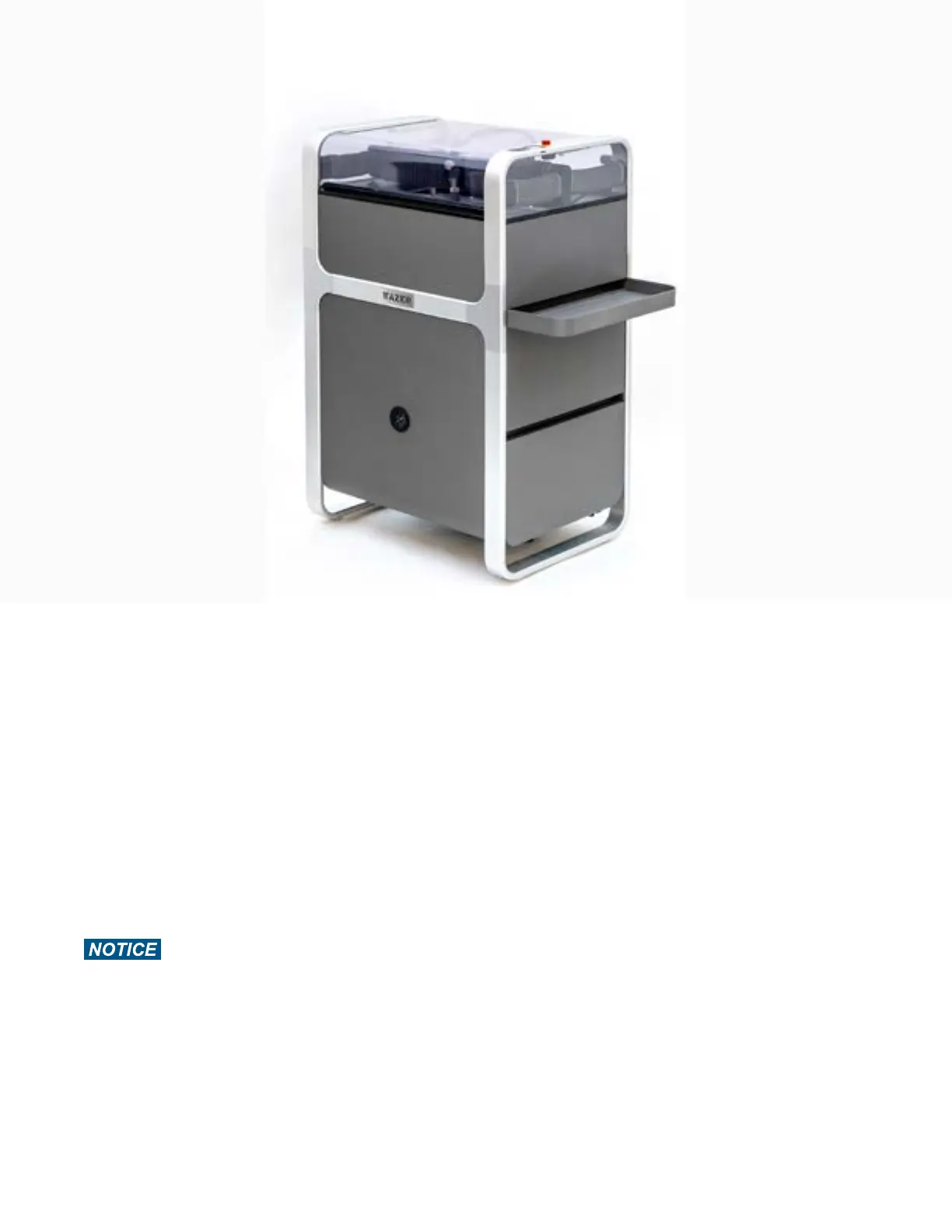

The nature of the water jet stream allows for very accurate cutting in thinner materials and the kerf

shape is still acceptable for most users up to 1” (25mm) thickness. Beyond that the WAZER Pro may still

be capable of cutting the material but it is important to remember that cut accuracy will decrease as the

material thickness is increased. Moreover, attempts to engrave or surface etching material with WAZER

Pro will result in damage of machine. Engraving and Etching are strictly prohibited.

15

Loading...

Loading...