113

DIAGNOSTICS AND TROUBLESHOOTING

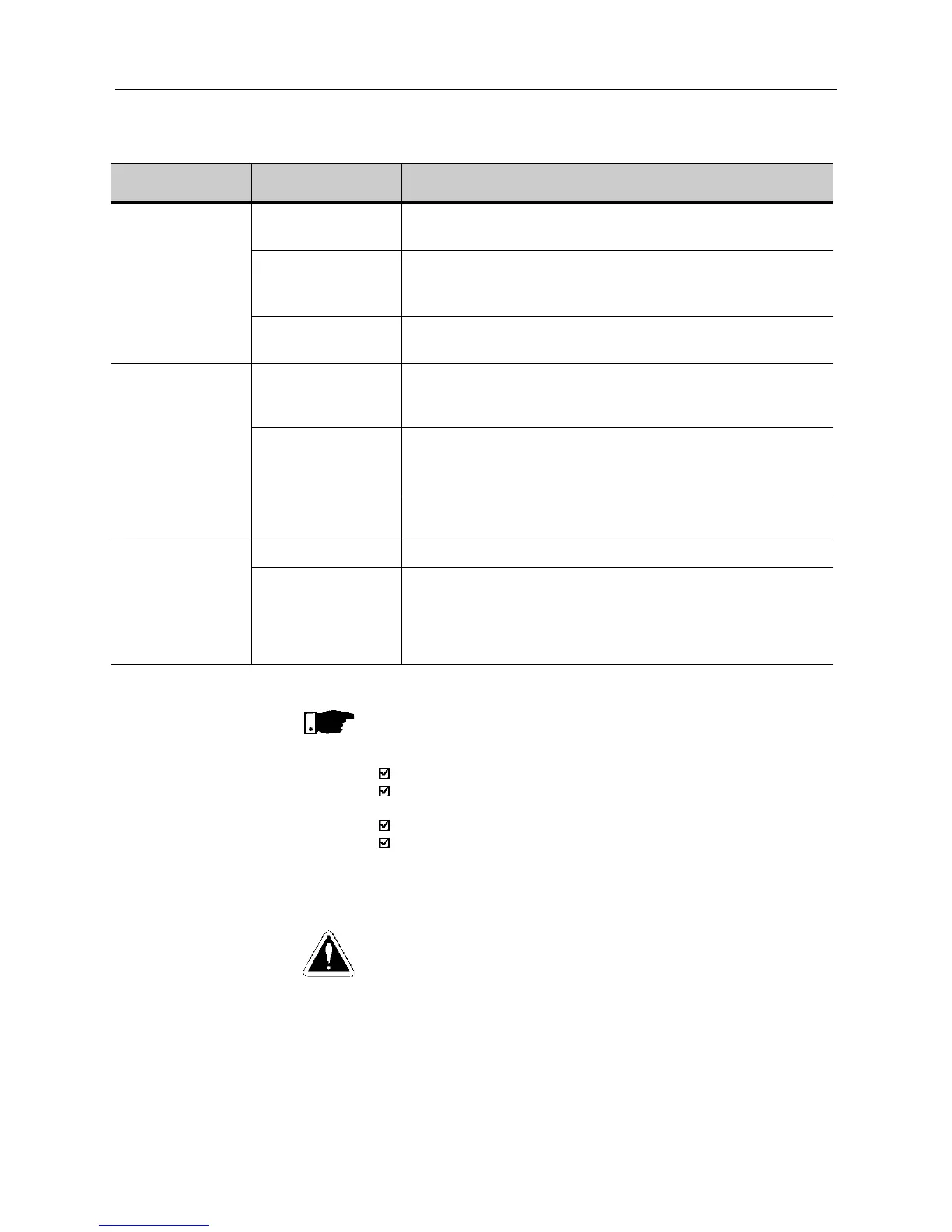

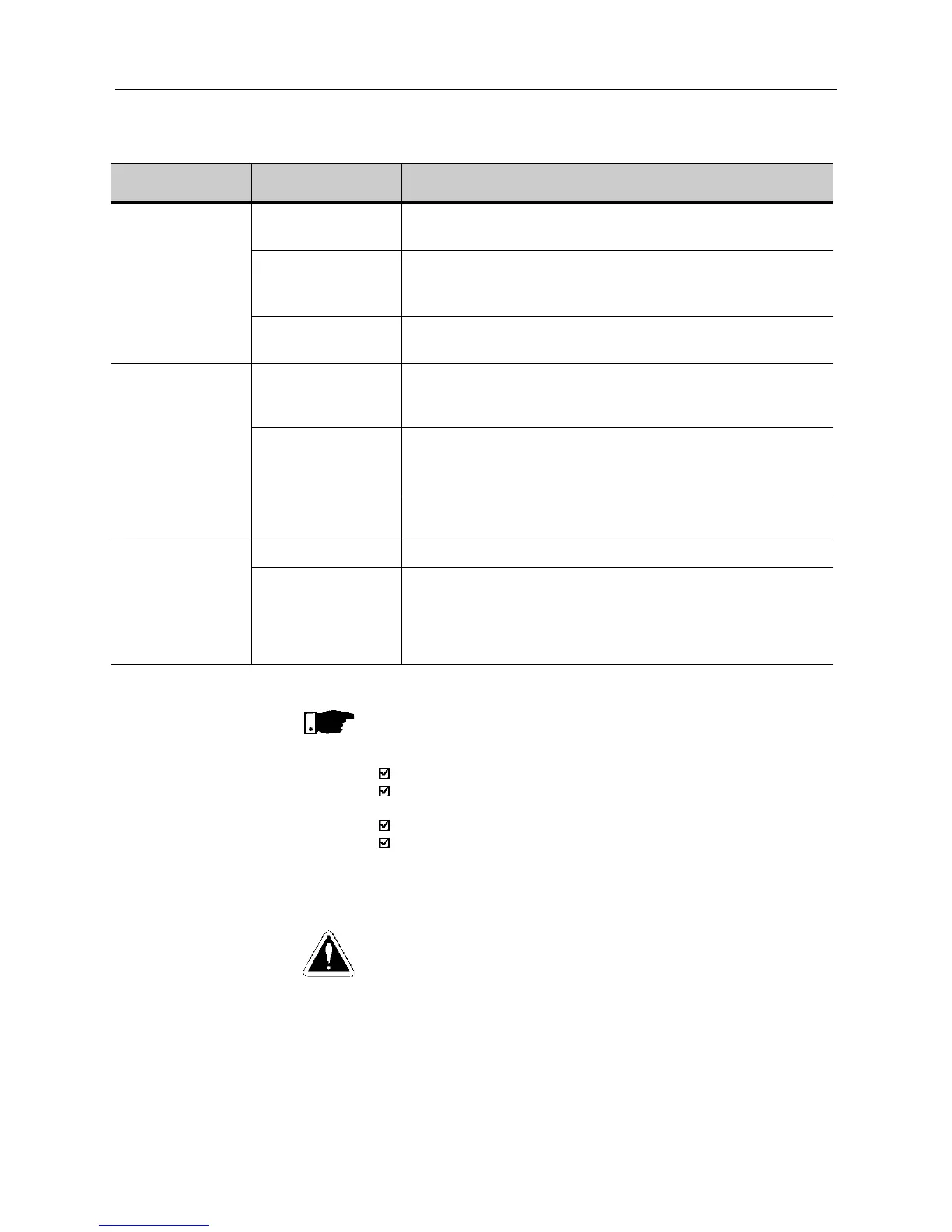

PROBLEM

POINT TO BE

CORRECTIVE ACTION

CHECKED

Motor speed Loose connections 1.Disable the inverter, switch OFF the power supply and tighten all

varies connections.

(oscillates) Defective speed 1.Replace the defective speed potentiometer.

potentiometer

Variation of the external 1.Identify the cause of the variation.

analog reference

Motor speed Programming error 1.Check if the contents of P133 (minimum frequency)

too high or (reference limits) and P134 (maximum frequency) are according to the motor

too low application.

Signal of the 1.Check the control signal level of the reference.

Reference Control 2.Check the programming (gains and offset) at P234 to P240.

Motor nameplate 1.Check if the used motor meets the application requirements.

data

Display OFF Keypad connection 1.Check the keypad connections to the inverter.

Power supply 1.The power supply must be within the following ranges:

200-240V models: - Min: 170V

- Max: 264V

380-480V models: - Min: 323V

- Max: 528V

NOTE!

When contacting WEG for services, please have the following data on

hand:

Inverter model;

serial number, manufacturing date and hardware revision, as indicated

on the inverter nameplate (refer to section 2.4);

Software version (refer to section 2.2);

information about the application and inverter programming.

7.3 CONTACTING WEG

7.4 PREVENTIVE

MAINTENANCE

DANGER!

Always disconnect the power supply voltage before touching any

component of the inverter.

Even after switching OFF the inverter, high voltages may be present.

Wait 10 minutes to allow complete discharge of the power capacitors.

Always connect the equipment frame to a suitable ground (PE) point.

Loading...

Loading...