132

CFW-08 OPTIONS AND ACCESSORIES

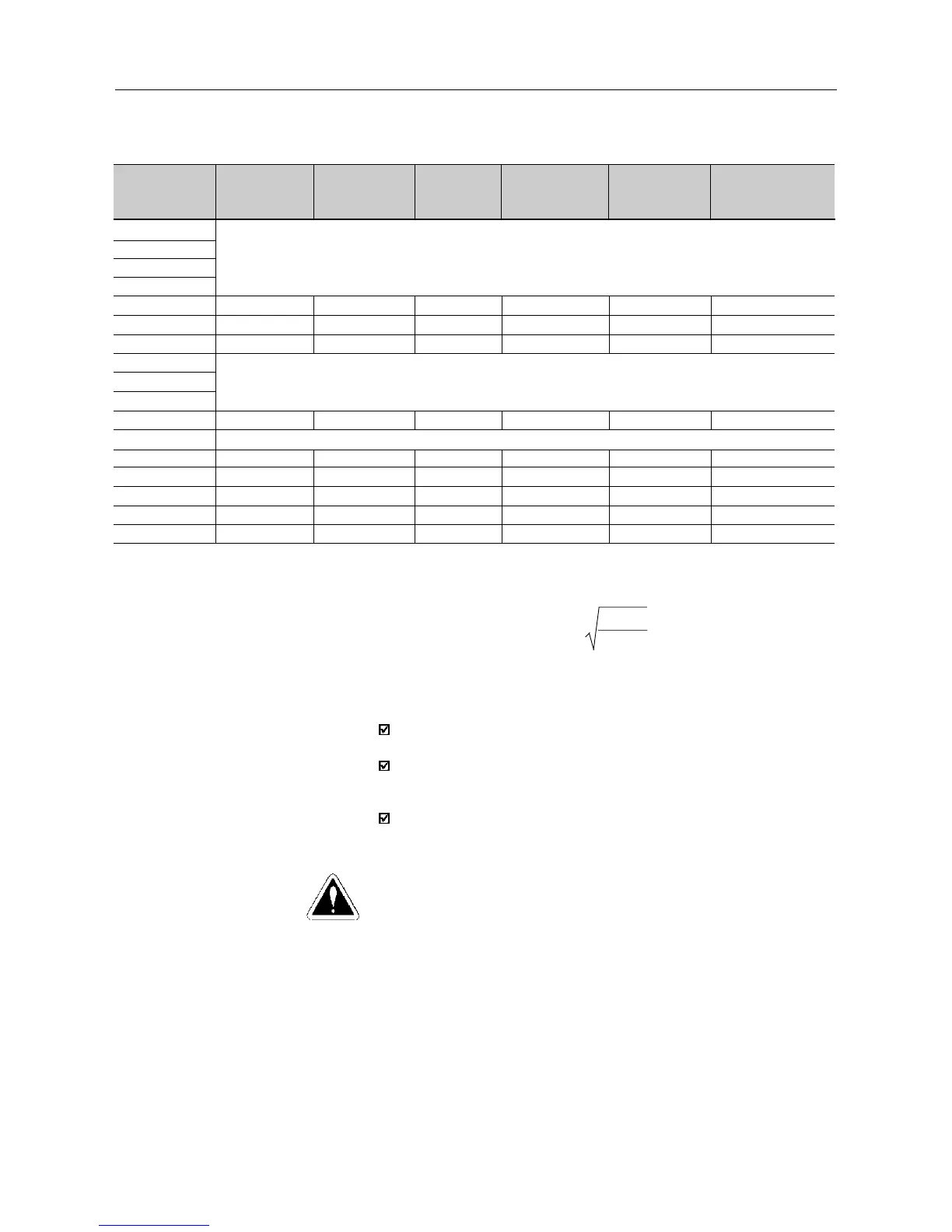

Inverter Model

1.6A / 200-240V

2.6A / 200-240V

4.0A / 200-240V

7.0A / 200-240V

7.3A / 200-240V

10A / 200-240V

16A / 200-240V

1.0A / 380-480V

1.6A / 380-480V

2.6A / 380-480V

2.7A / 380-480V

4.0A / 380-480V

4.3A / 380-480V

6.5A / 380-480V

10A / 380-480V

13A / 380-480V

16A / 380-480V

Maximum

Braking Current

10 A

15 A

20 A

6 A

6 A

8 A

16 A

24 A

24 A

RMS

Braking

Current (*1)

5 A

7 A

10 A

3.5 A

3.5 A

4 A

10 A

14 A

14 A

Recommended

Resistor

39 Ω

27 Ω

22 Ω

127 Ω

127 Ω

100 Ω

47 Ω

33 Ω

33 Ω

Recommended

Wiring

2.5 mm

2

/ 14 AWG

2.5 mm

2

/ 14 AWG

4 mm

2

/ 12 AWG

1.5 mm

2

/ 16 AWG

1.5 mm

2

/ 16 AWG

2.5 mm

2

/ 14 AWG

4 mm

2

/ 12 AWG

6 mm

2

/ 10 AWG

6 mm

2

/ 10 AWG

P

max

(Maximum

Resistor Power)

3.9 kW

6.1 kW

8.8 kW

4.6 kW

4.6 kW

6.4 kW

12 kW

19 kW

19 kW

P

rated

(Rated

Resistor Power)

0.98 kW

1.3 kW

2.2 kW

1.6 kW

1.6 kW

1.6 kW

4.7 kW

6.5 kW

6.5 kW

Braking not available

Braking not available

Braking not available

Table 8.5 - Recommended Braking Resistors

(*1) The rms braking current can be determined by:

I

rms

=

I

max

.

t

br

[min]

5

where t

br

corresponds to the sum of the braking times during the most

severe 5 minute cycle.

8.18.2 Installation

Connect the braking resistor between the +UD and BR power terminals

(refer to section 3.2.2).

Make this connection with a twisted pair. Run this cable separately

from any signal or control wire. Size the cable cross section according

to the application, by considering the maximum and the rms current.

If the braking resistor is installed inside the inverter panel, consider

the heat dissipated by the resistor when defining the panel ventilation.

DANGER!

The internal inverter braking circuit and the braking resistor can be damaged

when not correctly sized or when the line voltage exceeds the maximum

allowed value

In this case, the only guaranteed method to avoid burning the braking

resistor and eliminate risk of fire is the installation of a thermal overload

relay in series connected with the resistor and/or the installation of a

thermostat on the resistor body, wiring it in such a way that it disconnects

the inverter power supply in case of overheating, as shown in figure 8.22

below:

Loading...

Loading...