64

KEYPAD (HMI) OPERATION

NOTE!

(1) For parameters that can be changed with the motor running, the

inverter will use the new value immediately after it has been set. For

parameters that can be changed only with motor stopped, the inverter

will use this new value only after the key is pressed.

(2) By pressing the key after the reprogramming, the new

programmed value will be stored automatically and will remain stored

until a new value is programmed.

5.2.4 Parameter Viewing and

Programming

All CFW-08 settings are made through parameters. The parameter are

shown on the display by the letter P followed by a number:

Exmple (P101):

101 = Parameter Number

Each parameter is associated with a numerical value (parameter value),

that corresponds to the selected option among the available ones for this

parameter.

The parameter values define the inverter programming or the value of a

variable (e.g.: current, frequency, voltage).For inverter programming you

should change the parameter content(s).

To allow the reprogramming of any parameter value (except for P000 and

P121) it is required to set P000 = 5.

Otherwise you can only read the parameter values, but not reprogram

them. For more details, see P000 description in Chapter 6.

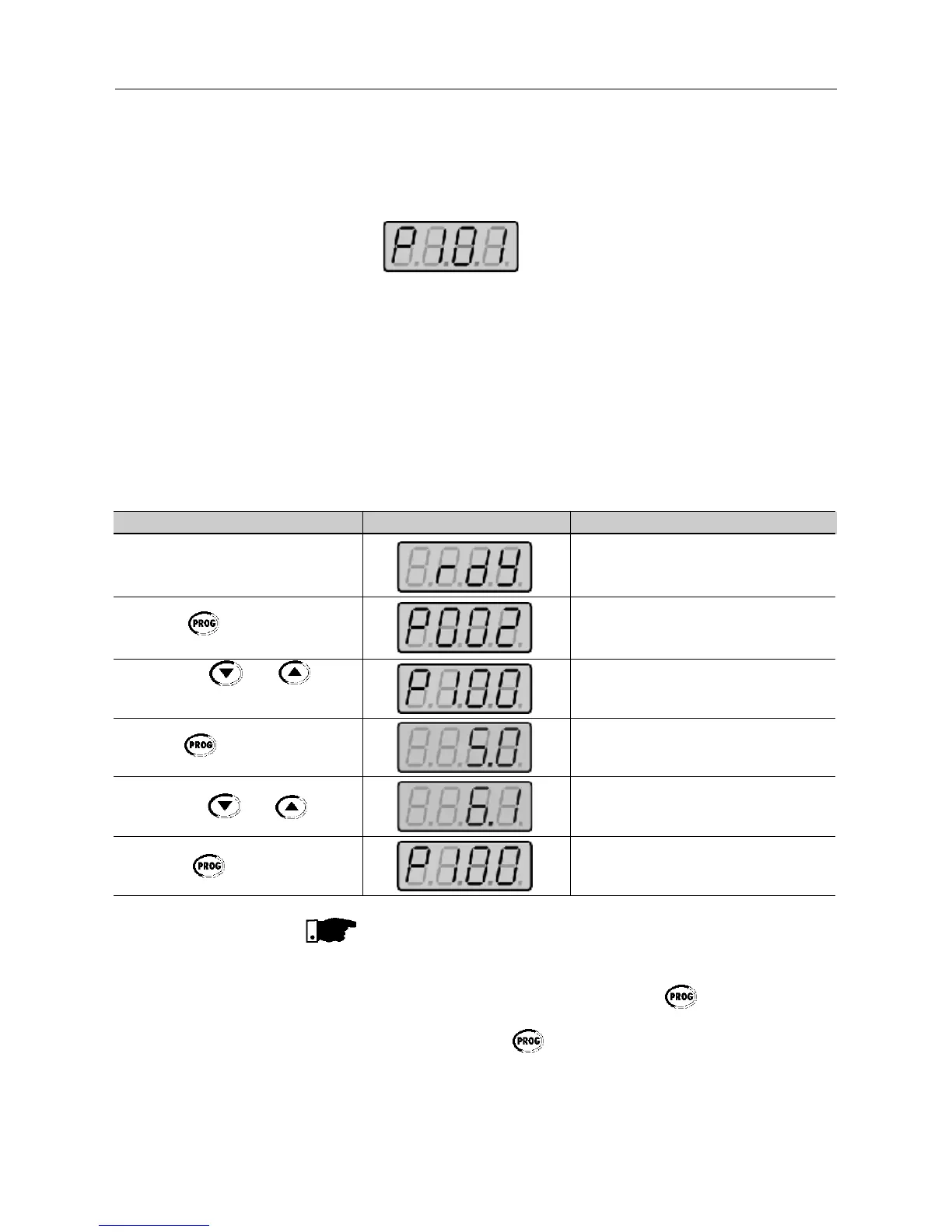

ACTION HMI DISPLAY DESCRIPTION

Turn ON the inverter

Press the key

Use the keys and to

reach P100

Press the key

Use the keys and keys

Press the key

Inverter is ready to be started

Select the desired parameter

Numerical value associated with the

parameter

(4)

Set the new desired value

(1) (4)

(1) (2) (3)

Loading...

Loading...