CARBON

MONOXIDE

"CO"/

LOW-CO

GENERATORS

IMPORTANT

INFORMATION

DESCRIPTION

Carbon monoxide

"CO"

is

a component of engine

eXhaust.

It

is

a colorless, tasteless,

odorless,

lighter than air poisonous

gas

that

can

kill

you

without

any

warning.

CO

poisoning

is

one

of

the

major

safety

risks

associated

with

boating. It

is

a

threat that must not

be

underestimated.

Westerbeke

Low-CO

generators

are

designed

to

reduce

normal

levels of

CO

in

the

engine exhaust

by

approximately

99%.

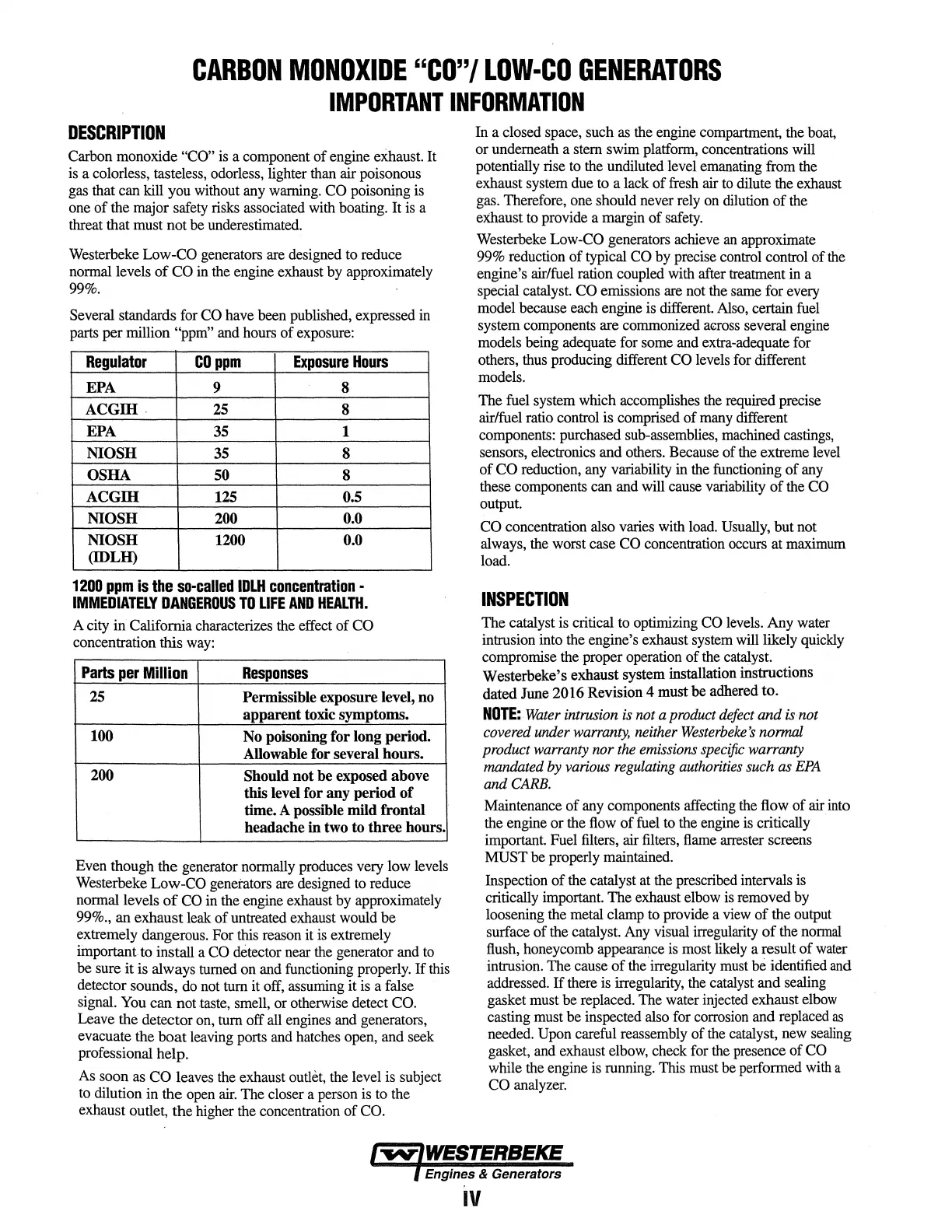

Several standards

for

CO

have

been

published, expressed

in

parts

per million

"ppm"

and

hours

of

exposure:

Regulator

CO

ppm

Exposure

Hours

EPA

9

8

ACGffi.

25

8

EPA

35

1

NIOSH

35

8

OSHA

50

8

ACGffi

125

0.5

NIOSH

200

0.0

NIOSH

1200

0.0

(IDLH)

1200

ppm

is

the

so-called

IDLH

concentration·

IMMEDIATELY

DANGEROUS

TO

LIFE

AND

HEALTH.

A city

in

California characterizes

the

effect

of

CO

concentration this

way:

Parts

per

Million

Responses

25

Permissible exposure

level,

no

apparent

toxic

symptoms.

100

No

poisoning for long period.

Allowable

for several hours.

200

Should not

be

exposed above

this

level

for any period of

time. A

possible

mild frontal

headache

in

two

to three hours.

Even though the

generator

normally

produces

very low

levels

Westerbeke Low-CO

generators

are

designed

to

reduce

normal levels

of

CO

in

the

engine exhaust

by

approximately

99%.,

an exhaust

leak

of untreated

exhaust

would

be

extremely dangerous. For this

reason

it

is

extremely

important

to

install a

CO

detector

near

the

generator

and

to

be sure it is always

turned

on

and

functioning

properly.

If

this

detector sounds,

do

not

tum it

off,

assuming

it

is

a false

signal.

You

can not taste,

smell,

or

otherwise

detect

CO.

Leave

the detector

on,

tum off

all

engines

and

generators,

evacuate the boat

leaving

ports

and

hatches

open,

and

seek

professional help.

As

soon

as

CO

leaves

the

exhaust

outlet,

the

level

is

subject

to

dilution

in

the

open

air.

The closer a

person

is

to

the

exhaust outlet, the higher

the

concentration

of

CO.

In

a closed

space,

such

as

the

engine

compartment,

the

boat,

or underneath a stem

swim

platform,

concentrations

will

potentially rise

to

the

undiluted level

emanating

from

the

exhaust system

due

to a lack of

fresh

air

to

dilute

the

exhaust

gas.

Therefore,

one

should never

rely

on

dilution of

the

eXhaust

to

provide a margin of

safety.

Westerbeke

Low-CO

generators

achieve

an

approximate

99%

reduction of typical

CO

by

precise

control

control of

the

engine's air/fuel ration coupled

with

after treatment

in

a

special catalyst.

CO

emissions

are

not

the

same

for

every

model because

each

engine is

different.

Also,

certain

fuel

system components are

commonized

aeross

several

engine

models

being adequate

for

some

and

extra-adequate for

others,

thus

producing different

CO

levels

for

different

models.

The fuel system which

accomplishes

the

required

precise

air/fuel ratio control

is comprised of

many

different

components:

purchased

sub-assemblies,

machined

castings,

sensors, electronics and

others.

Because of

the

extreme

level

of

CO

reduction,

any

variability

in

the

functioning of

any

these

components

can and will

cause

variability of

the

CO

output.

CO

concentration also

varies

with

load.

Usually,

but not

always,

the

worst

case

CO

concentration

occurs

at

maximum

load.

IV

INSPECTION

The catalyst is critical to

optimizing

CO

levels.

Any

water

intrusion into

the

engine's exhaust

system

will

likely

quickly

compromise

the

proper

operation

of

the

catalyst.

Westerbeke's exhaust system installation instructions

dated June

2016 Revision 4 must be adhered to.

NOTE:

Water

intrusion

is

not a

product

defect

and

is

not

covered

under

warranty,

neither

Westerbeke

s normal

product

warranty

nor

the

emissions

specific

warranty

mandated

by

various

regulating

authorities

such

as

EPA

andCARB.

Maintenance of

any

components

affecting

the

flow

of air

into

the engine or

the

flow

of

fuel

to

the

engine

is

critically

important. Fuel

filters,

air

filters,

flame

arrester

screens

MUST

be

properly

maintained.

Inspection of

the

catalyst

at

the

prescribed intervals is

critically

important.

The

exhaust

elbow

is

removed

by

loosening

the

metal

clamp

to

provide a

view

of the

output

surface of

the

catalyst.

Any

visual

irregularity

of

the

nonnal

flush,

honeycomb

appearance

is

most

likely

a result of

water

intrusion. The

cause

of

the

irregularity

must

be identified

and

addressed.

If

there

is

irregularity,

the

catalyst

and

sealing

gasket must

be

replaced. The

water

injected

exhaust

elbow

casting

must

be

inspected

also

for

corrosion

and

replaced

as

needed.

Upon

careful reassembly of

the

catalyst,

new

sealing

gasket,

and

exhaust

elbow,

check

for

the

presence

of

CO

while

the

engine

is

running.

This

must

be

performed

with

a

CO

analyzer.

Loading...

Loading...