ROOM SEALED FLUE OPTIONS

I

NSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR CAMRAY KITCHEN 12/18-18/25-25/32

8 716 113 000a (01/07)

17

PRE -

INSTALLATION

R

OOM SEALED FLUE OPTIONS

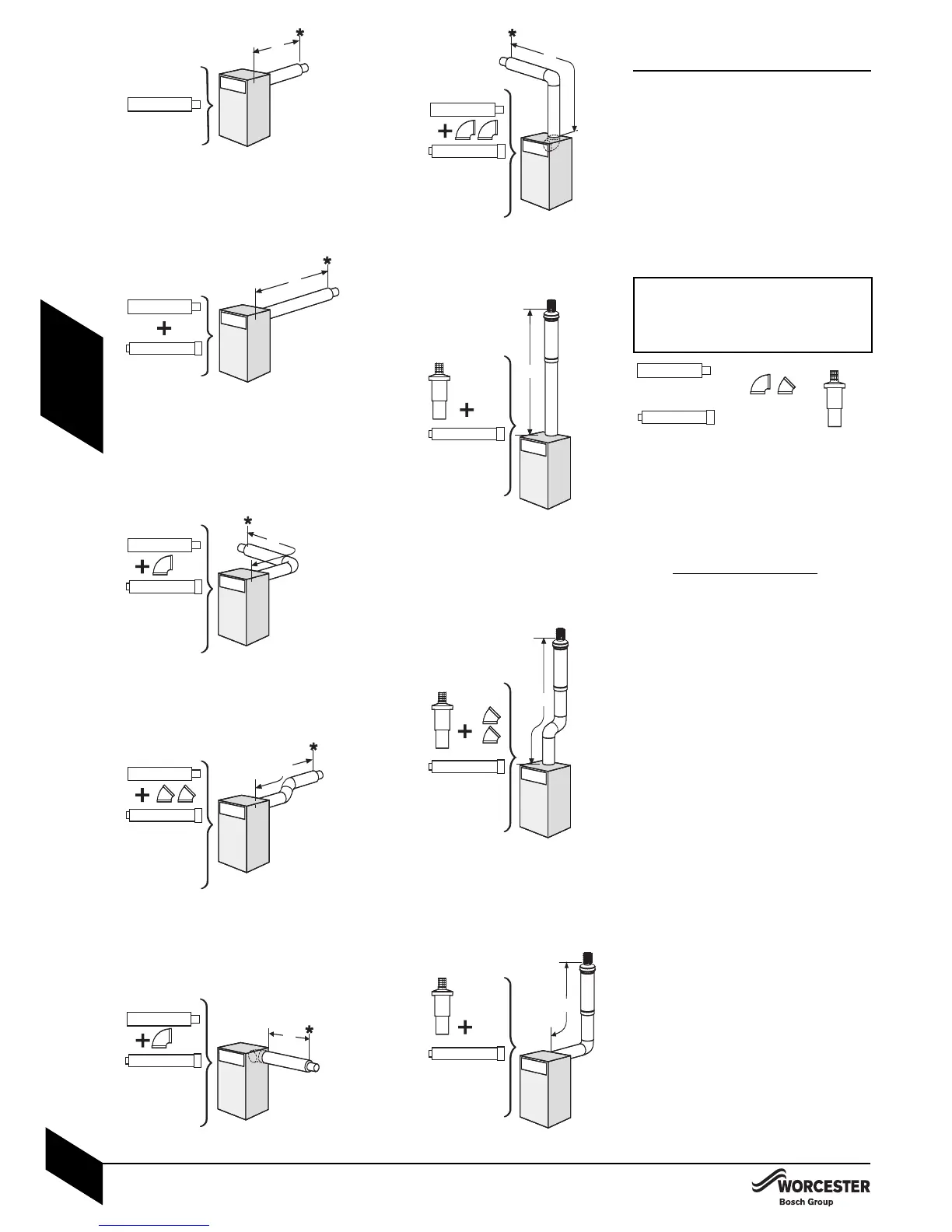

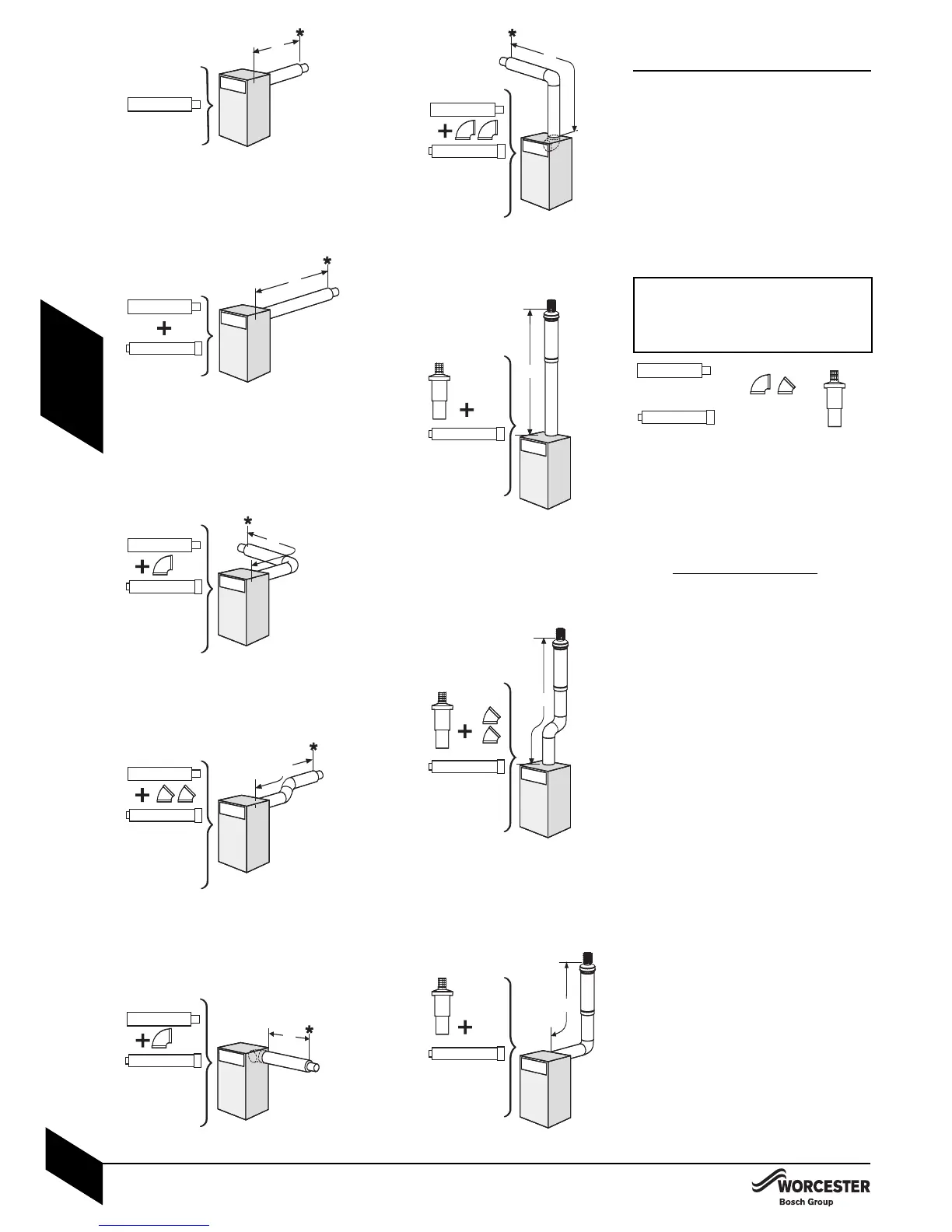

The diagrams (opposite) show the components

used and the maximum flue length (L) for

each flue configuration.

In all cases L is measured from the outside of

the boiler casing.

• To achieve the maximum flue length (L), a flue

section will have to be reduced in length.

• Only the flue terminal or straight flue

extensions can be reduced in length by

cutting.

• The flue terminal end can be fitted from the

inside or outside of the building.

IMPORTANT:

All horizontal sections must rise away

from the boiler by 52mm per metre (3°) to

allow the condensate to drain back to the

boiler.

A - Horizontal terminal

B - Straight flue extension

C - Flue bend 90°

D - Flue bend 45°

E - Vertical Terminal Kit (incl. 90° elbow)

Calculating the flue length:

Measure the total flue length required, noting

that the max

imum straight flue length including

the terminal is:

Horizontal 80/125mm Ø: 4000mm (excluding

120mm of terminal extending outside the building)

Vertical 80/125mm Ø & 100/150mm Ø:

8000mm (measured from the boiler top panel).

Then reduce the total straight flue length for

each extra flue bend (excluding the vertical flue

kit 90° elbow) by:

1000mm for 90°

500mm for 45

°

Flue Extension lengths:

Horizontal & Vertical 80/125mm Ø: 1000mm

overall length.

Effective length when engaged into sockets

within the flue run is 950mm.

Flue Terminal lengths:

Horizont

al 80/125mm Ø: 720mm

Vertical 80/125mm Ø: 1080mm + cage

V

ertical 1

00/

150mm Ø: 1290mm + cage

* to outside wall.

** The 180/125 to 100/150mmØ vertical

adaptor must be fitted vertically at the lowest

point of the vertical section of the flue.

Failure to fit the adaptor vertically will cause

the condensate to pool within the flue and

will adversely affect the flue’s per

formance.

Loading...

Loading...