STARTING THE APPLIANCE

IMPORTANT: Never run the appliance when

the appliance/system is unpressurised

(sealed systems) or empty.

14Check the oil supply is correctly fitted and

in good working order before turning on

the oil supply valves to the boiler.

4Turn on the main oil supply valve at the tank

and draw off oil until a steady flow of clear

uncontaminated oil can be seen as follows:

• The oil supply to the boiler should be

primed before the burner is operated to

avoid unnecessary pump wear.

• The use of an oil suction pump will prime

and flush through any oil supply set up

simply and easily. Alternatively the

following procedures can be used:

4Single pipe gravity feed systems:

4Disconnect the flexible oil pipe and open

the isolating valve to discharge the oil into a

suitable container.

4If a top entry tank has been used the

pipework will need to be primed before the

oil will discharge under gravity.

4When completed, close the isolating valve,

reconnect the flexible oil pipe.

4Double pipe sub-gravity feed systems

and single pipe suction lift with de-aerator:

4Prime the oil supply pipework to prevent oil

pump damage .

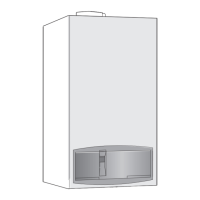

4To prime a de-aerator, disconnect the

flexible oil inlet hose (F) from the isolation valve

and place in a container of kerosene (G).

Connect a spare flexible oil hose (E), to

discharge into container (G). Open the

isolating valve, turn on the power to the boiler

and set the programmer to ON. Prime the

de-aerator until there is a steady flow of oil into

container (G). Turn off the boiler then

reconnect the flexible oil inlet hose (F).

4Turn on the boiler, the oil level in the de-aerator

will drop as the oil is used until the oil is drawn

from the tank. If the de-aerator empties and the

burner locks out before the oil is drawn from

the tank prime the de-aerator again.

4Open the isolating valve and the oil pump

bleed valve (A) to discharge into a suitable

container once the boiler is started up.

4Switc

h on the electricity supply to the boiler

.

4Set the programmer to ON.

4Turn on the boiler control thermostat.

4Allow the burner to run through to 'lock-out'

indicated by the illumination of the lockout

indicator (

H

), (

note: some systems will not

loc

k out

).

4If lockout occurs wait 2 minutes then press

the lockout reset button ( I ).

4Repeat the procedure at least 3 times or

until a steady stream of oil, without air, runs

from the bleed port, then relock bleed port.

4Switc

h off the boiler.

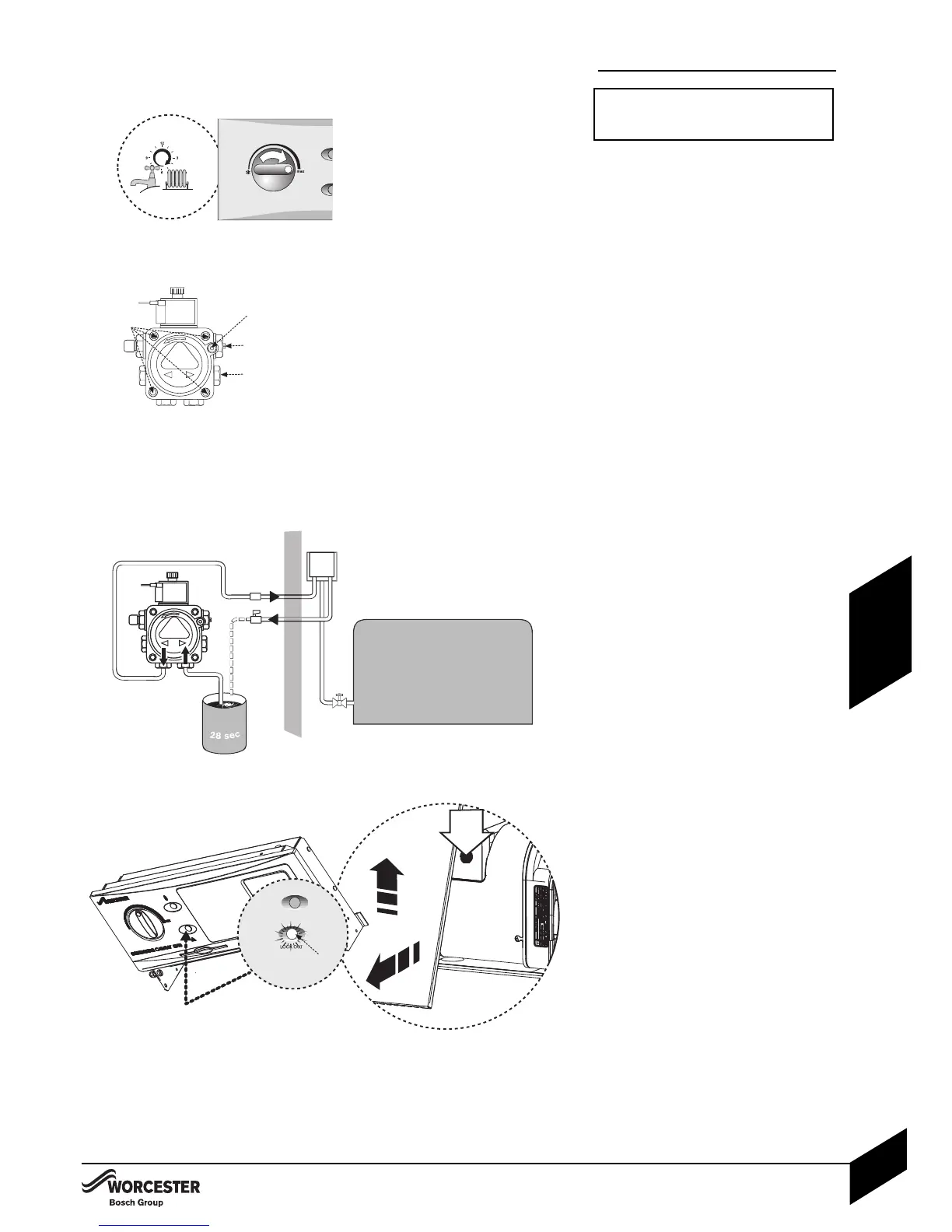

4Remove the oil pump filter, clean with

kerosene and refit.

The internal filter is accessed by removing the

oil pump cover.

4Safely dispose of the container/discharge.

S

T

ARTING THE APPLIANCE

I

N

S

TALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR CAMRAY KITCHEN 12/18-18/25-25/32

8 716 113 000a (01/07)

34

COMMISSIONING

TAN K

Loading...

Loading...