INSTALLATION

COMMISSIONING

SAFETY:

All relevant safety precautions must be undertaken.

Protective clothing, footwear, gloves and safety

goggles must be worn as appropriate.

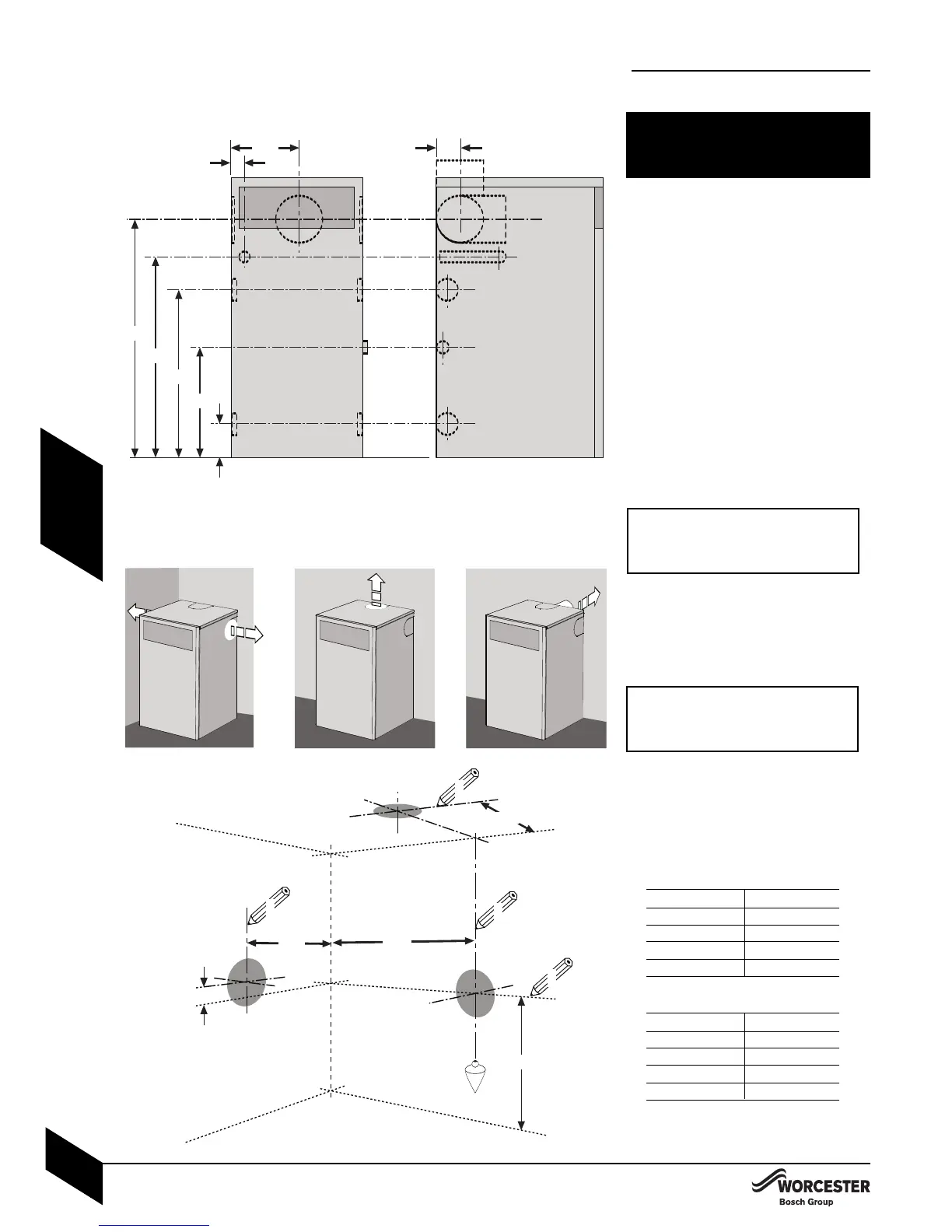

PIPEWORK POSITIONS:

A to E (opposite) show the flue and pipe positions:

A - Flow/open vent 1” BSP 12/18, 18/25.

1

1

/

4

” BSP 25/32.

B - Primary drain/cold feed

3

/

4

” Ø BSP.

C - Return 22mm Ø copper 1

2/18, 18/25.

28mm Ø copper on 25/32 model.

D - Flue outlet 80/125mm Ø.

E - Condensate outlet 21.5mm Ø.

NOTE: For servicing purposes, keep

condensate and pressure relief discharge

pipes away from components and pipework

connections.

IMPORTANT: The flue and pipework

openings are covered with tabbed blanks.

Remove carefully as necessary.

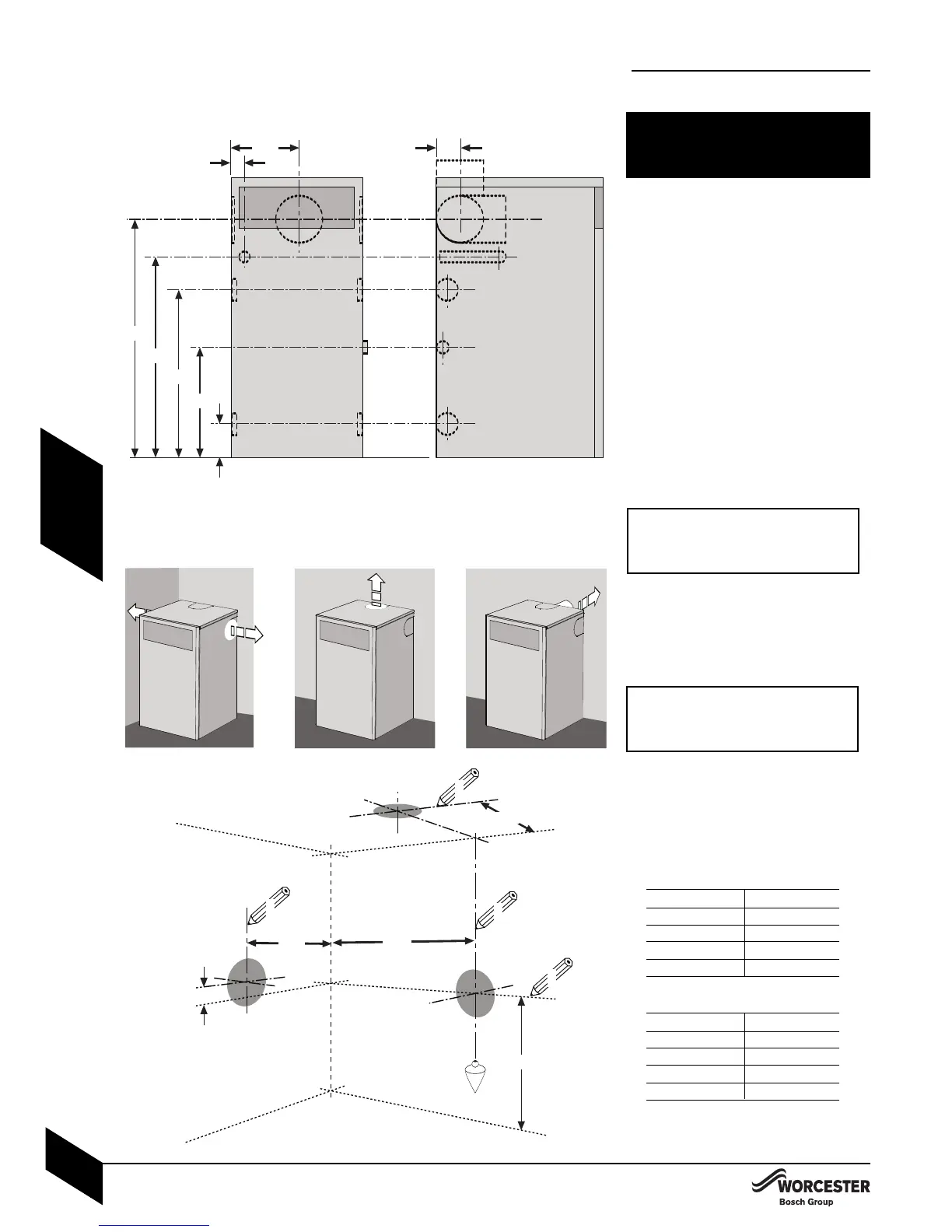

FLUE OPENING:

4 Follow the diagram opposite to mark the

centre of the flue (1, & 2) for rear opening,

(2 & 3) for side opening or

(1 & 4) for top opening.

** IMPORTANT: for horizontal flues, increase

this height by 52mm for every 1000mm of

horizontal length that the flue opening is

away from the

boiler

.

N

OTE: all horizontal flue sections must rise away

from the boiler by 52mm per metre to ensure that

condensate flo

ws back into the boiler for safe

discharge via the condensate waste pipe.

4 Make an opening (F, G or H) through the wall

using a core drill or similar at a size relative to

the wall thic

kness as shown below:

125mm Ø flue:

Wall thickness Flue hole size

150 - 240mm 155mm Ø

240 - 330mm 160mm Ø

330 - 420mm 165mm Ø

420 - 500mm 170mm Ø

150mm Ø flue:

Wall thickness Flue hole size

150 - 240mm 180mm Ø

240 - 330mm 185mm Ø

330 - 420mm 190mm Ø

420 - 500mm 195mm Ø

4 Clear away any debris.

CAUTION: Ensure there are no pipes,

electric cables, damp proof courses or

other ha

zards before drilling.

PIPEWORK POSITIONS &

FLUE OPENING

PIPEWORK POSITIONS &

FLUE OPENING

I

NSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR CAMRAY KITCHEN 12/18-18/25-25/32

8 716 113 000a (01/07)

19

RS - 155

CF - 170

R

S - 155

CF - 1

7

0

1

55

Loading...

Loading...