INSPECTION AND SERVICE

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR CAMRAY KITCHEN 12/18-18/25-25/32

8 7

16 113 000a (01/0

7)

43

SERVICING

& S

P

AR

E

S

INSPECTION AND SERVICE

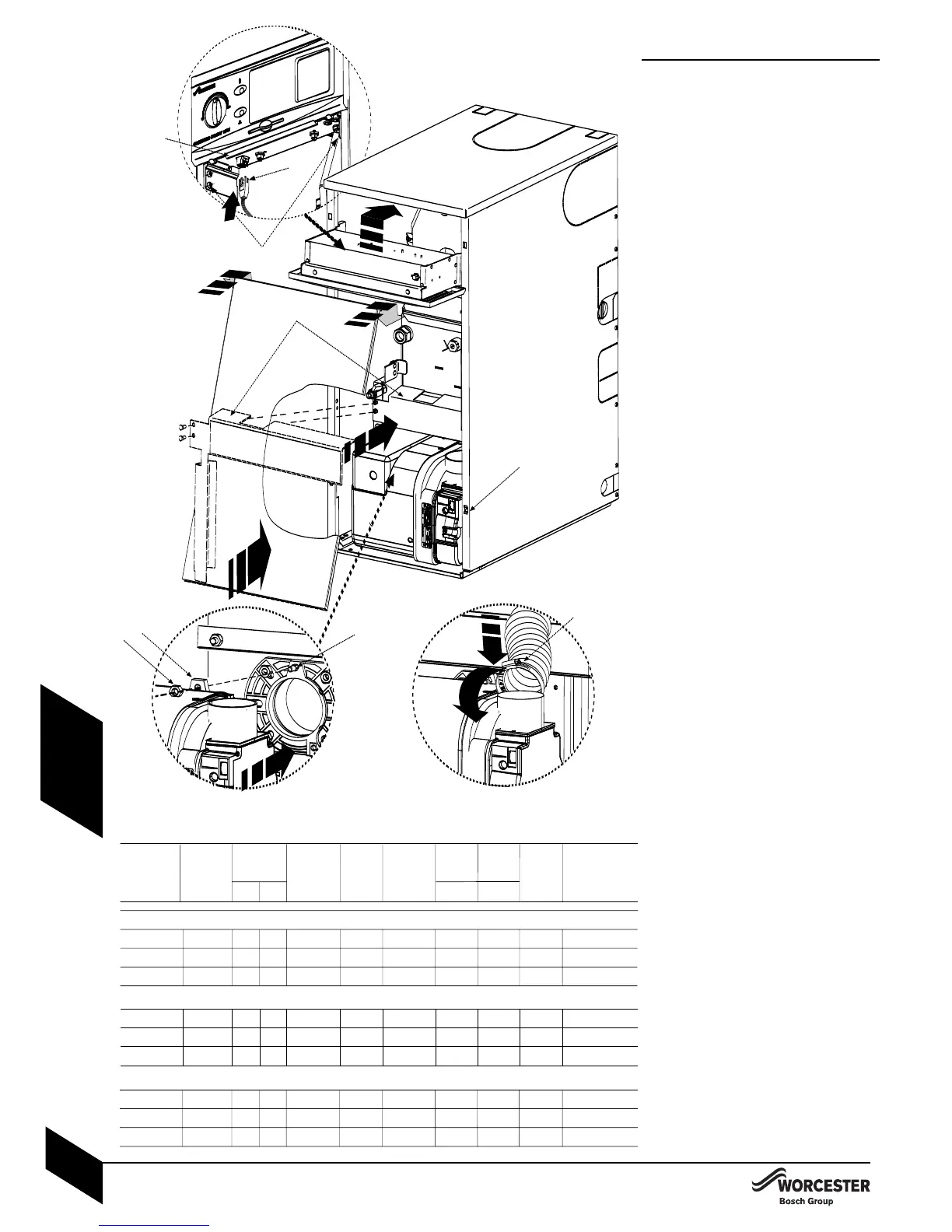

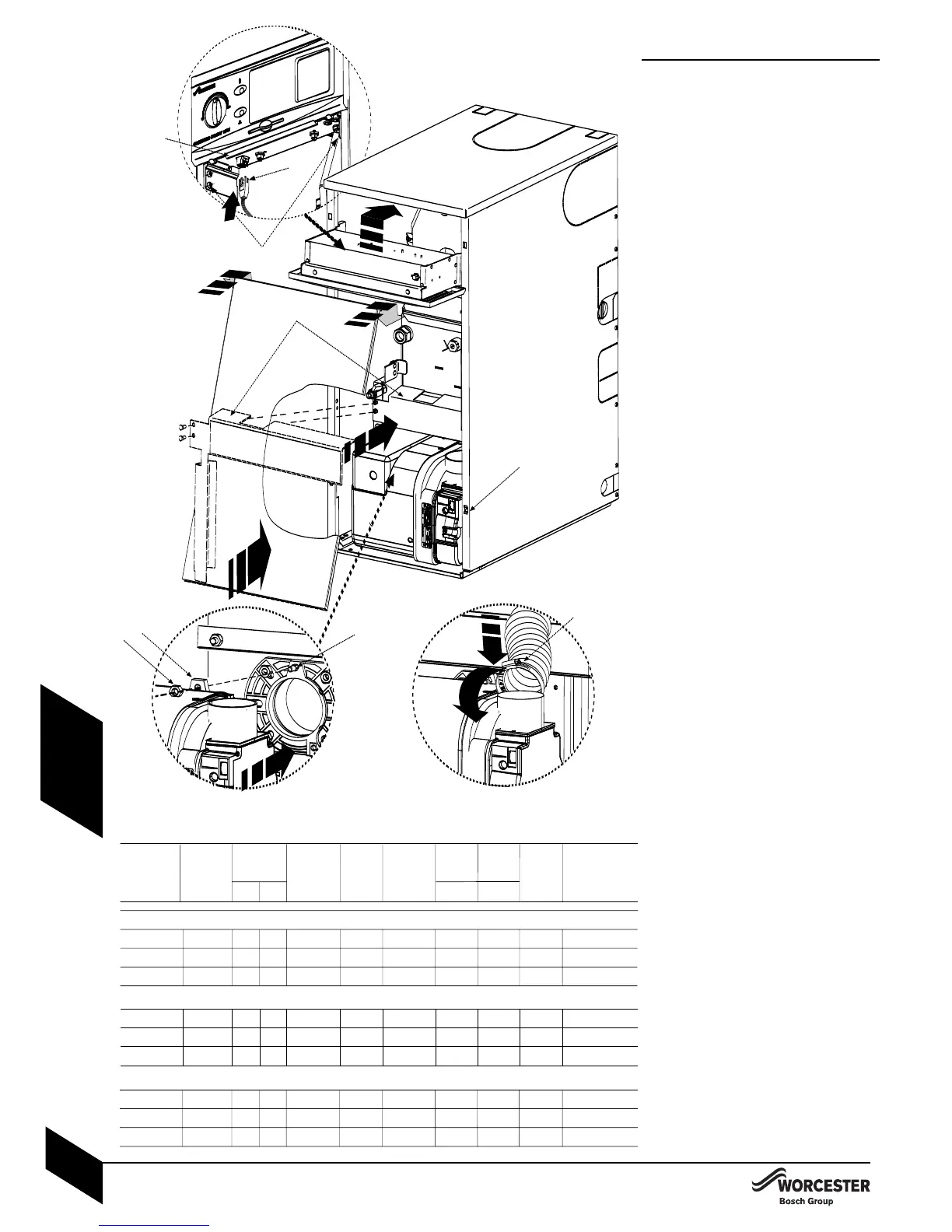

Re-commission the burner:

14 Align burner combustion head into boiler

collar.

4 Locate the burner retainer (A) over the

threaded lug on the collar (B). Push the

burner firmly onto the flange and secure in

place with the retaining nut (C). Tighten

sufficiently but refrain from overtightening.

4 Check that the burner is seated correctly

on its mounting flange and that the oil

pipe/s are not trapped in front of or

underneath the burner.

2

4 Refit the deflector plate (D) and secure

with screws (E). Ensure that the flexible oil

pipe/s are not positioned between the

deflector plate and the combustion

chamber door.

3

4 Attach air duct pipe and tighten clip (F) to

secure to the burner air intake.

44 Swing control box bac

k up into operating

position and retain in place by replacing

the two securing screws (G) in the bottom

locations

.

4 Plug burner lead (H) into control box.

4 Run the burner and check the combustion

settings as indicated in the table below

and check that the smoke reading is

between 0 - 1.

54 Locate the top edge of panel ( I ) onto the

supporting ledge ( J ) and secure at the

bottom by gently pushing home the ball

studs into the retaining slots ( K ).

Remember always to apply pressure at the

edges of the panels to avoid damage.

Aft

er service handover:

4Make a note of the date of any water treatment.

4Set the controls back to the users

requirements.

4Complete the service interval record at the

bac

k of this manual and the CD1

1 or an

equivalent form

.

4If the appliance is unused and exposed to

freezing conditions; shut off all the mains

supplies, isolate the boiler and drain the

system and boiler, including the secondary

heat exchanger.

* 25/32 model for 25kW remove the plastic

air guide (see page 36).

Loading...

Loading...