P

I

P

EW

O

R

K C

O

N

N

ETIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR CAMRAY KITCHEN 12/18-18/25-25/32

8 716 113 000a (01/07)

23

INSTALLATION

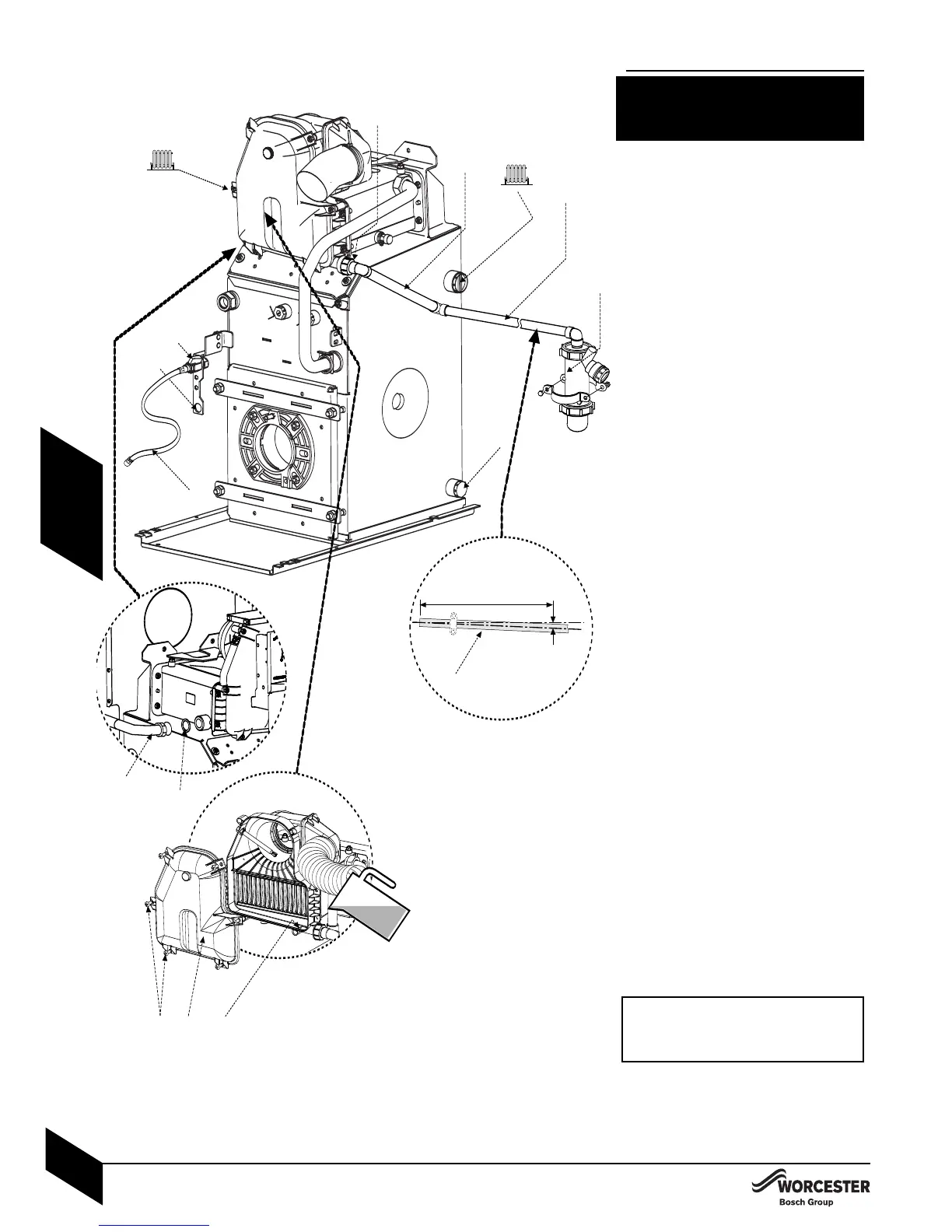

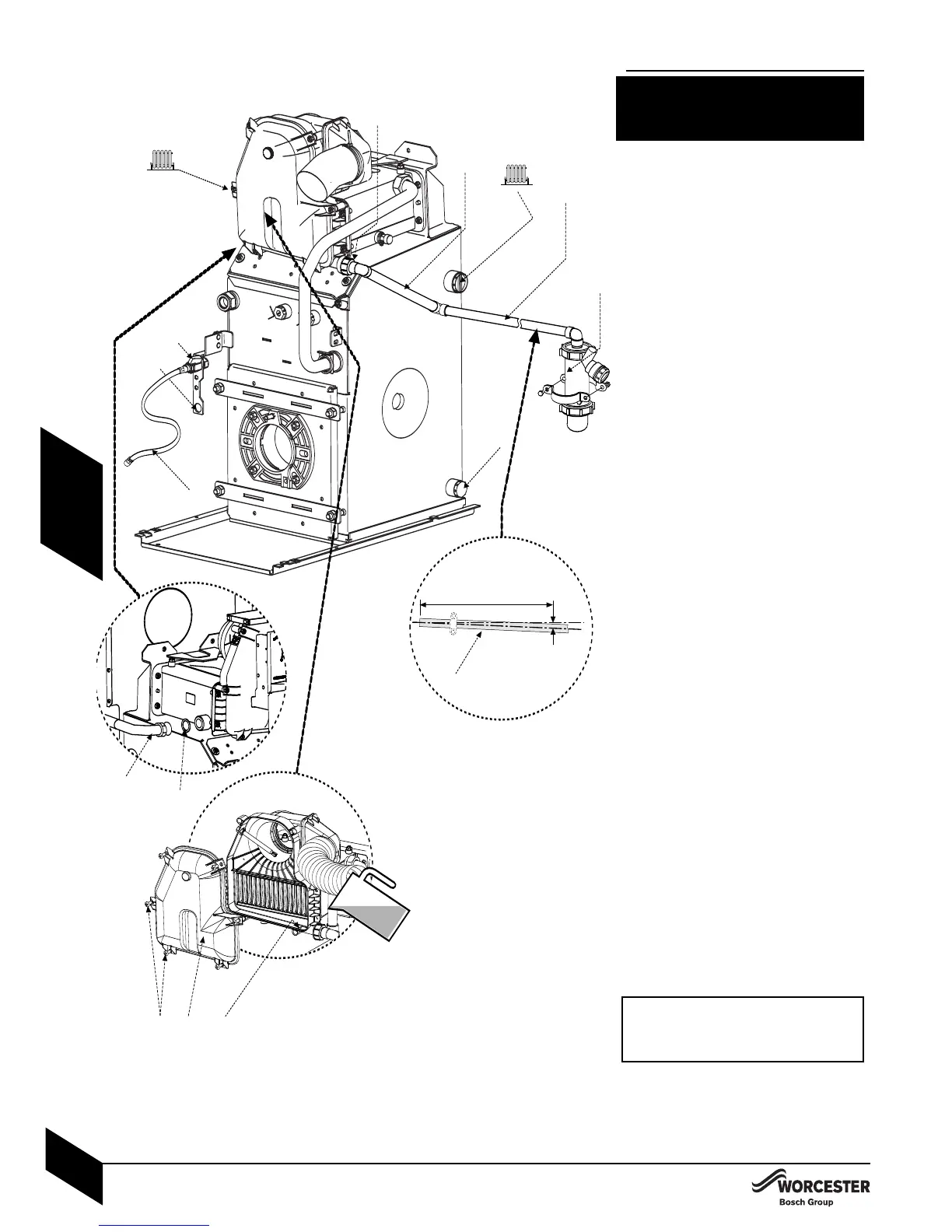

PIPEWORK CONNECTIONS

CAUTION: ISOLATE THE OIL & WATER

MAINS SUPPLY BEFORE STARTING ANY

WORK AND OBSERVE ALL RELEVANT

SAFETY PRECAUTIONS.

A - Flow/open vent 1” BSP on 12/18,

18/25 (1

1

/

4

” BSP on 25/32 models)

B - Primary drain/feed

3

/

4

” BSP

C - Return 22mm Ø copper (28mm Ø on

25/32 models)

D - Fixing point for optional return oil pipe.

E

- Oil isolating valve (10mmØ)

F - Flexible oil pipe

G - Flue manifold condensate outlet

H - Condensate outlet (21.5mmØ) -

supplied

I - Condensate pipe - not supplied

J - Condensate trap with wall clamp - supplied

WATER CONNECTIONS:

4Remove the transit bungs from the pipework

connections on the boiler.

NOTE: Surplus water may be present due to

factory testing

.

4Ensure all pipework is clean.

4Fit the return pipe (C) to the secondary heat

exchanger using the sealing washer supplied.

4Align water pipework and connect.

4Check that all unused sockets have been capped.

OIL SUPPLY CONNECTIONS:

4Route the oil supply pipe along the left

side of the boiler and connect to the isolating

valve (E) and ensure the valve is closed.

4Connect the flexible oil pipe (F) to the isolating

valve (E).

CONDENSATE CONNECTION:

4Fit the elbow (supplied) onto the

condensate pipe (H) (supplied).

4Fit the sealing washer to the condensate

pipe (H) and connect it to the flue manifold

outlet (G).

4Fit the condensate trap in a serviceable

position using the clamp supplied.

4C

onnect 21.5mm polypropylene pipe ( I ) (not

supplied) to the condensate pipe (H) and

condensate trap (J) before terminating to

waste.

4Ensure that the condensate pipe runs away

from the boiler at a constant fall of 50mm

(min.) for every metre.

4Carefully pour 500ml of water into the

condens

at

e collect

ion (

K

) t

o fill condens

ate

trap.

4Check the water is running away and the

condensate pipework joints are water tight.

4Check the flue manifold seal is undamaged

and seated correctly.

4Refit flue manifold access cover (

M

) and

secure with screws (L).

IMPORTANT: The condensate trap must be

correct

ly filled t

o prevent the possibility of

potentially harmful flue products escaping

via the condensate pipework.

A

B

C

located at the side

of the secondary

heat exchanger

H

J

G

I

D

I

E

F

Return pipe

(C)

W

asher

K

M

L

Loading...

Loading...