CAUTION: ISOLATE THE OIL & WATER

MAINS SUPPLY BEFORE STARTING ANY

WORK AND OBSERVE ALL RELEVANT

SAFETY PRECAUTIONS.

OIL BURNER:

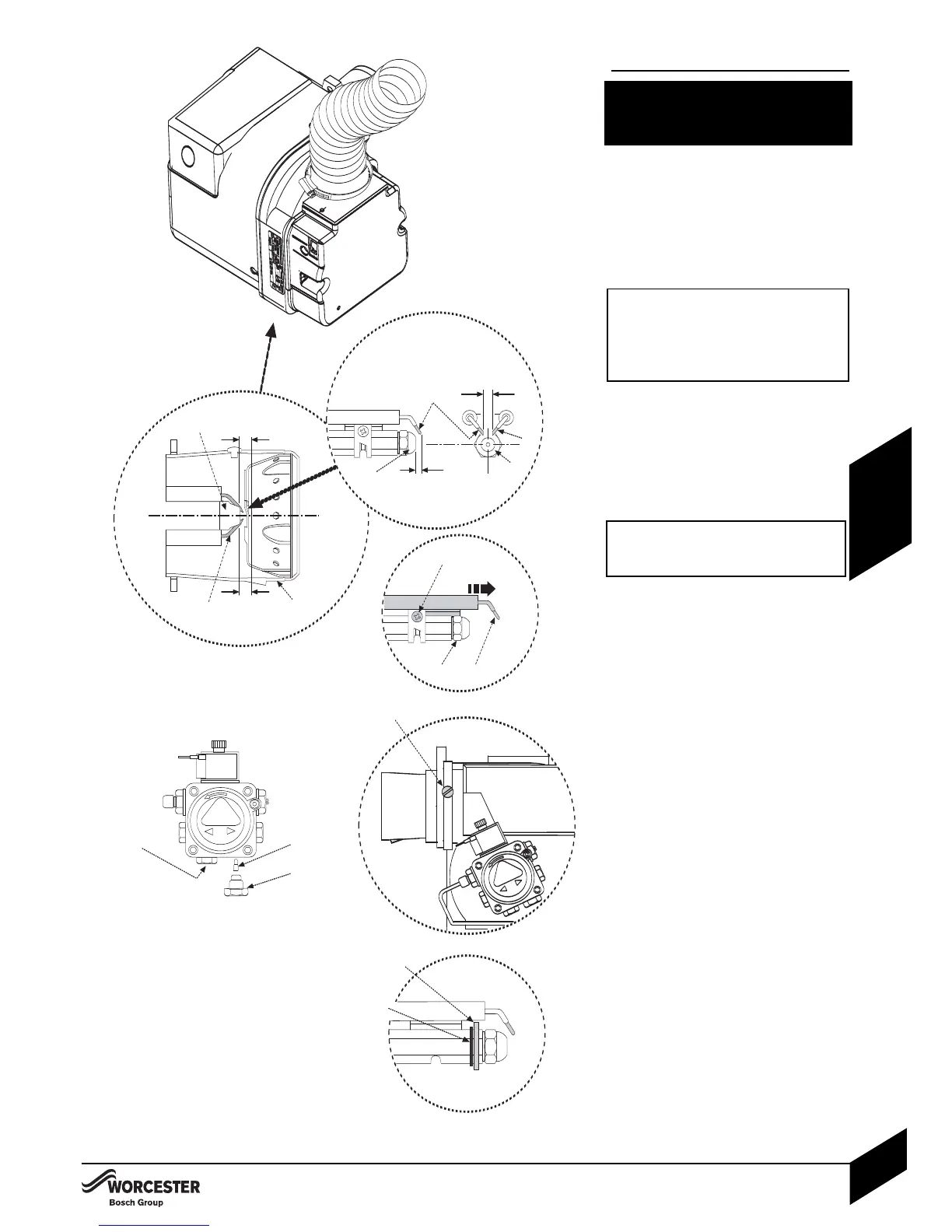

14 Check the nozzle (A) and electrode (B)

settings are correct as shown opposite.

4 Ensure nozzle (A) is aligned centrally within

the combustion head (C).

4 Inspect for any visible defects.

2 IMPORTANT: Before removing or fitting a

nozzle (A), loosen screw (D) and move

the electrodes (B) forward.

Aft

er refitting check that the electrode

gaps are correct, as shown opposite.

NOTE: the 12/18 model has a brass deflection

washer and locating circlip behind the nozzel.

These must be in place for the correct

operation of the burner.

IMPORTANT: Whenever replacing the

combustion head, ensure that the

photocell is lined up with the sight hole.

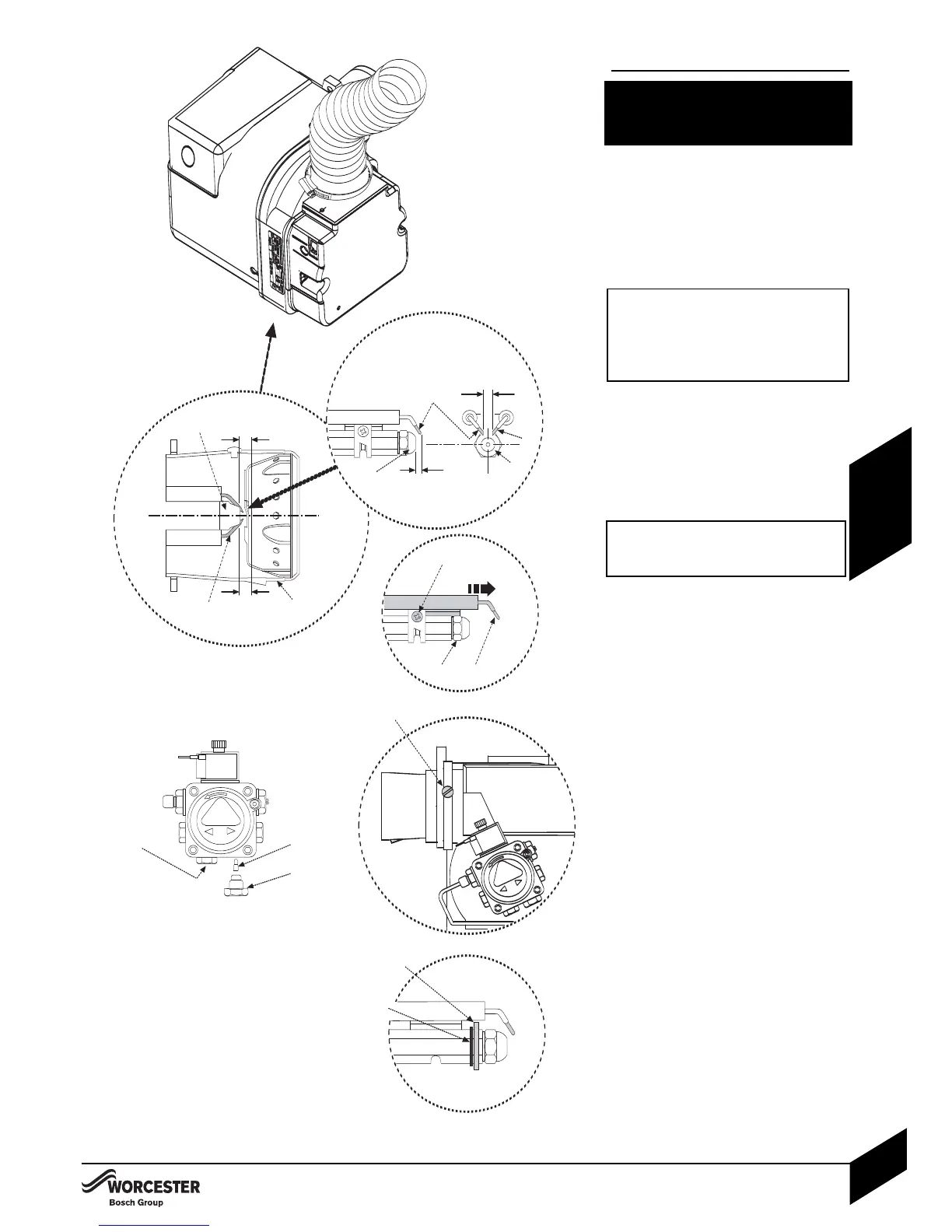

OIL PUMP:

Connecting the oil pump for a single pipe

system:

4 The pump is factory set for single pipe

operation with the flexible oil pipe fitted.

4 Chec

k connections before use.

Converting the oil pump for a double pipe

system:

14 Check the inlet pipe connection (1).

4 Unscrew return plug (2).

4 Screw in by-pass screw (3).

24 C

onnect the flex

ible oil pipe

ret

urn

hose

(not supplied) to the oil pump and return

pipe fixing (D on page 23) and tighten

to secure.

Loading...

Loading...