Multi 9420 Dissolved oxygen (D.O.)

ba75964e04 04/2015 71

Criteria for a stable

measured value

The Stability control function checks whether the measured values are stable

within the monitored time interval.

The minimum duration until a measured value is assessed as stable is the mon-

itored time interval. The actual duration is mostly longer.

7.1.2 Measuring the temperature

For reproducible D.O. measurements, it is essential to measure the tempera-

ture of the test sample.

IDS D.O. sensors measure the temperature with a temperature sensor inte-

grated in the IDS sensor.

7.2 FDO

®

Check procedure

7.2.1 Why should you check the sensor?

With the FDO

®

Check procedure, you can find out in a simple manner

whether the FDO

®

925 D.O. sensor should be cleaned or calibrated.

7.2.2 When should you check the sensor?

Checking can be useful in the following cases:

When the check interval has expired

(the [check] status indicator is displayed).

If the measured values seem to be implausible

If you assume that the sensor cap is contaminated or at the end of

its lifetime

After the sensor cap was exchanged

Routinely within the framework of the company quality assurance

7.2.3 Carrying out the FDO

®

Check procedure

FDO

®

Check

procedure

Check in water vapor-saturated air.

Use the check and storage beaker (FDO

®

Check) to carry out theFDO

®

Check

procedure.

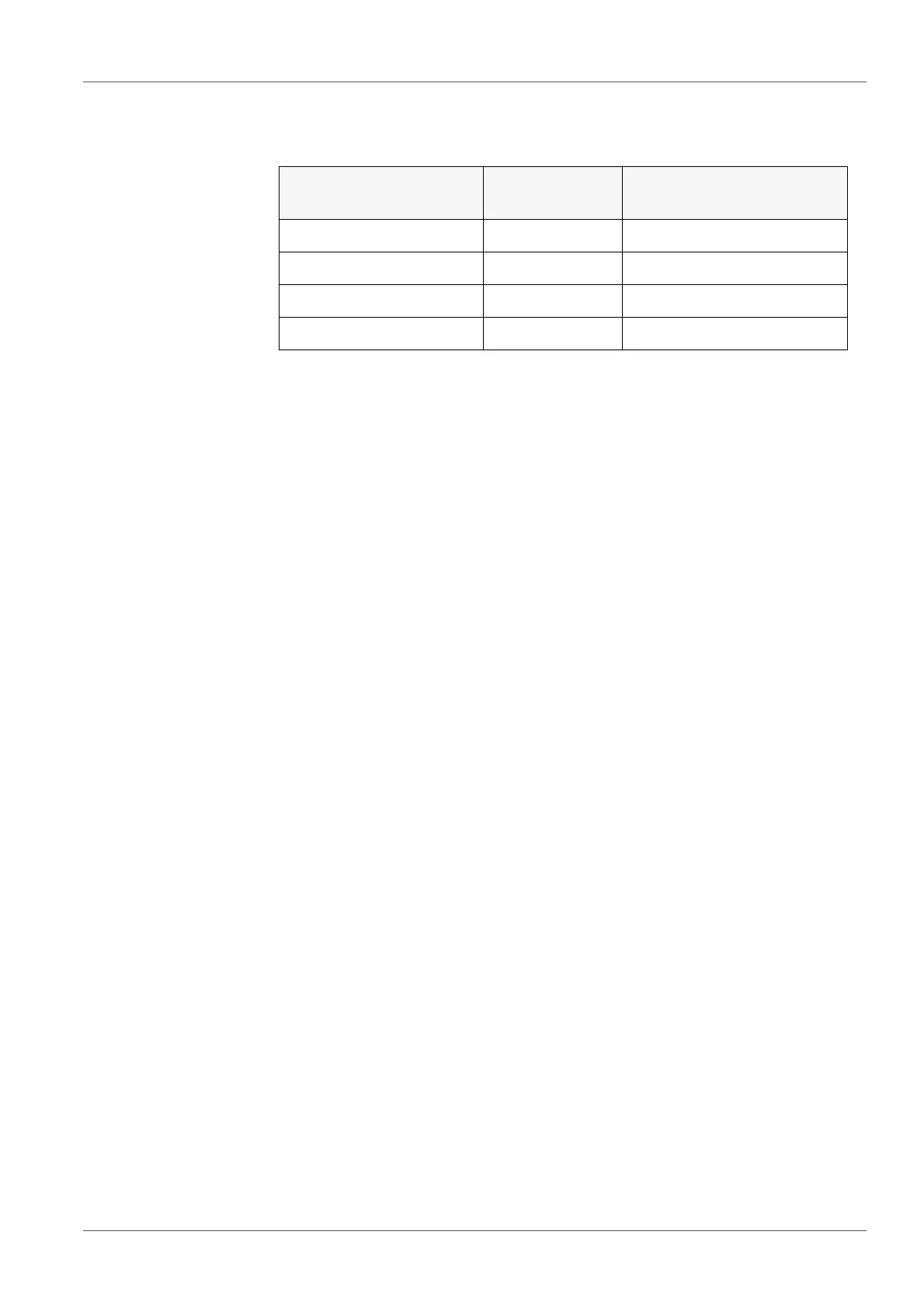

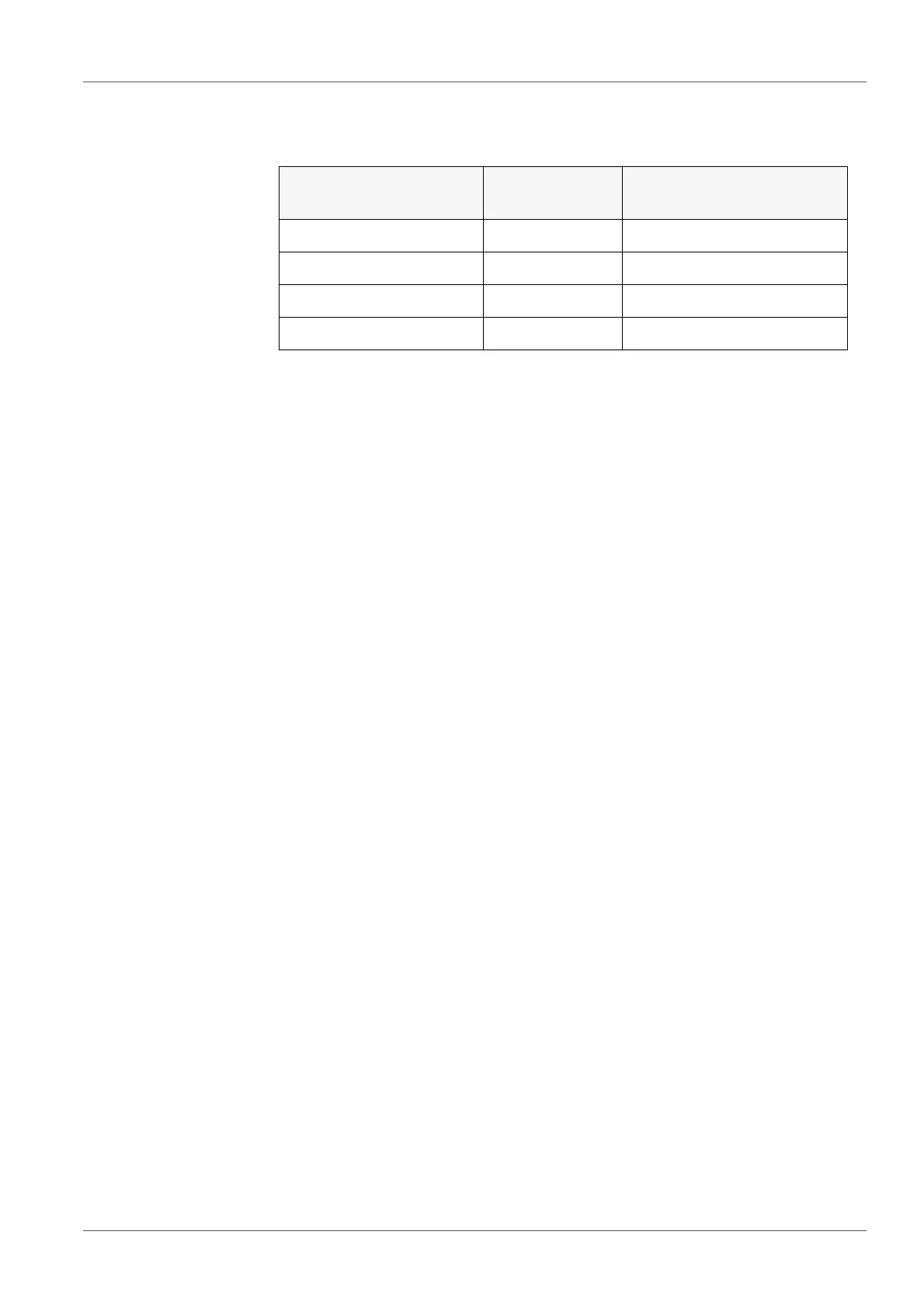

Measured parameter Time interval Stability in the time

interval

D.O. concentration 20 seconds

∆ : better than 0.03 mg/l

D.O. saturation 20 seconds

∆ : better than 0.4 %

D.O. partial pressure 20 seconds

∆ : Better than 0.8 mbar

Temperature 15 seconds

∆ : Better than 0.5 °C

Loading...

Loading...