Installation Xerox

®

Versant™ 2100 Press

Customer Expectation and Installation Guide Xerox Confidential 34

Floor Information

Floor Specifications

The installation site floor must meet certain specifications and

requirements before the system is installed:

The customer must ensure and approve the floor composition and

strength.

The surface of the floor should be a hard, non-compressible surface such

as bare concrete, wood, or industrial grade floor tile. If the surface is

compressible/covered (for example, carpets or non-industrial tile), the

covering should be removed under the press.

Mobility (floor) plates are required for any installation occurring on

carpeting.

Additionally, mobility assist devices (supplied by the customer), such as

masonite or plywood, must be used for installations occurring on

ceramic tiles, uneven floors (which meet required specifications), or

carpeting. The mobility assist devices will ensure that the flooring is not

damaged during the installation process.

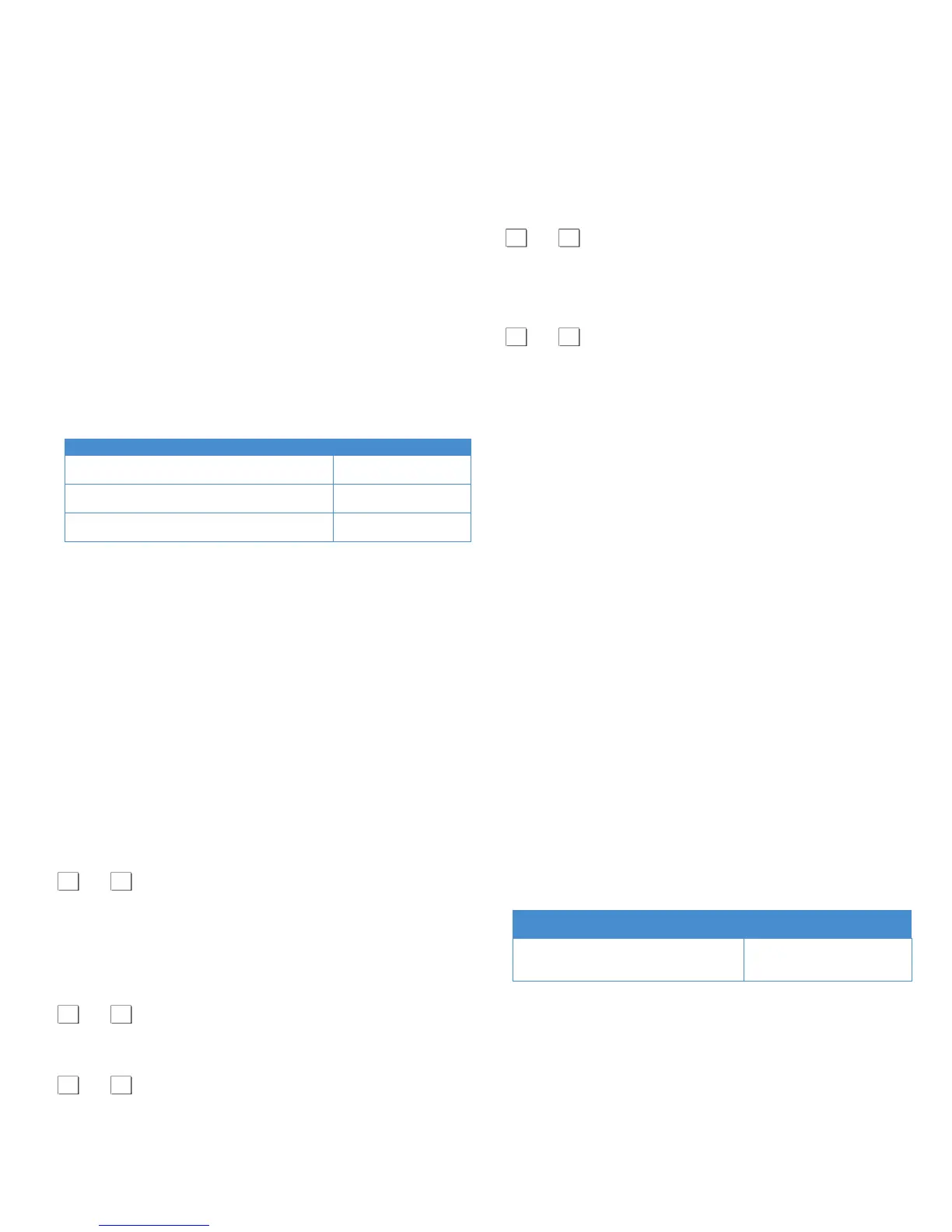

Floor Requirements

The following table lists the floor readiness activities and the person

responsible for completing that activity.

Activity Responsible Person

Certify the floor strength from the loading dock

to the installation site

Customer (and

structural engineer)

Certify the floor strength and composition for

the installation site

Customer (and

structural engineer)

Certify or remove

loor covering under press

location (if applicable)

Customer (and

structural engineer)

Floor Strength Information

As part of the structural inspection process, a structural engineer should

inspect and approve the site where the system will be installed.

The customer site floor must safely support the weight of the entire press

and all its components. This includes the weight of all optional feeding and

finishing devices that the customer intends to add. Therefore, the

structural engineer and customer must evaluate and calculate the weight of

all the modules and optional accessories (including any third-party

finishing devices) in order to accurately determine the appropriate floor

strength and weight distribution needed at the installation site.

For product specification information on all third-party finishing devices,

refer to the specific third-party customer documentation.

Floor Worksheets

Floors/Floor Coverings Worksheet

Are the floors or floor coverings along the delivery route concrete or

industrial tile?

Yes No

If No: Customer must supply Carriers with hardboard/plywood or metal

plates/Masonite for rolling the press over the floors that are not concrete

or industrial tile.

Raised Floors Worksheet

Are there any raised floors on the delivery route?

Yes No

If Yes: Has a structural engineer or the customer signed off/approved that

the floors meet requirements?

Yes No

If No: Sign off/Approval is required.

NOTE: Carriers MUST lift all the raised-floor tiles on the route to ensure

the support structure integrity.

NOTE: Carriers will use hardboard or metal plates (such as masonite or

plywood) when rolling the press over the raised floor.

Floor Strength/Load Worksheet

Has a structural engineer or the customer signed off/approved that the

floor meets requirements?

Yes No

If No: Sign off/Approval is required.

Is the floor of the pathway route and destination area able to hold the

combined weight of the press left and right modules (1,248 lb./566.1 kg)?

Yes No

If No: An alternative route/destination site must be considered.

Mobility Plate Information

Mobility Plates

All installations occurring on carpeted flooring surfaces require the

installation of a mobility plate to allow the product to be moved during

normal maintenance.

Mobility plates are available from your Sales Representative.

Mobility Plate Kit

Part number: 497K5270 is the only mobility plate kit that is available for

the press and its optional feeding/finishing devices. The kit includes the

following contents:

1 Plate

4 Bracket assemblies

8 Nuts

1 set of kit instructions

Each plate is:

19.68 in./500 mm (width) x 29.52 in./750 mm (depth)

0.12 in./3 mm (thickness)

19 lb./8.6 kg

Optional kits must be ordered for any optional feeding/finishing devices

that are attached to the press. Refer to the next section in this guide for

specific information on each feeding/finishing device.

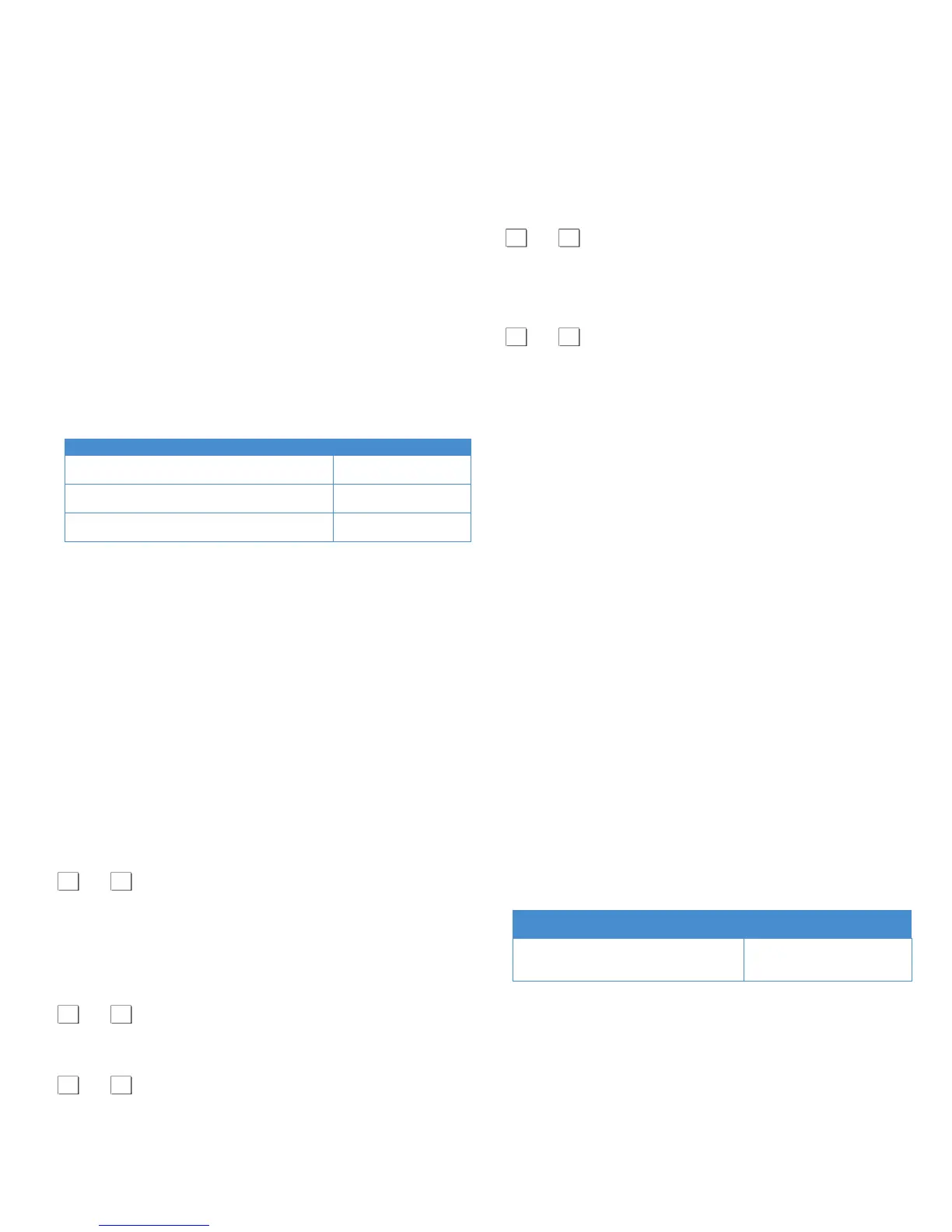

Mobility Plate Charts

The following tables show the number of mobility plates required for the

base configuration and for the various optional feeding and finishing

devices.

Base Configuration

Module name

Required number of kits

Press (Advance HFC + Left and Right

modules)

5 kits (3 for the left and right

modules and; 2 for the

Advanced HCF)

Optional Devices Chart

The following table lists the number of ADDITIONAL plates required

for the various optional devices. The number of plates listed does not

include the base press (left and right modules and Advanced HCF).

NOTE: The Interface Module is required with any system configuration that

has one or more finishing device, except the Offset Catch Tray (OCT).

Loading...

Loading...