Product Overview Xerox

®

Versant™ 2100 Press

Customer Expectation and Installation Guide Xerox Confidential 1

1 Product Overview

Introduction

This document is intended to help you understand the performance and

capabilities of the Xerox® Versant™ 2100 Press, including information on

optional accessories. Installation planning information is provided later in

this document and it contains specifications and guidelines for installing

your press. Specifications and data in this document include Xerox and

customer proprietary information. The customer will use all reasonable

efforts to safeguard the document, will not disclose its contents to third

parties, and should only circulate it within the organization on a need-to-

know basis.

Product Highlights

Productivity

Improvements in imaging and fusing technology enable more sellable

prints to more customers

- New compact belt fuser drives up to 100 ppm speeds (single-

sided letter/A4)

- New Ultra HD Resolution that produces incredibly smooth

sweeps and spectacularly sharp images, graphics and text.

- New low gloss, low melt EA dry ink/toner that provides brilliant,

vibrant and powerful images

- Full Width Array for automatic color control and media

alignment

Production Accurate Registration (PAR) ensures you spend more time

printing and less time adjusting the press

- Provides a combination of sensors, hardware and software

controls from the tray to the finisher

- Ensures the registration is true from the first print to the last run

Increased media latitude and mixed media performance improvements

enable more applications

- Supports an incredible array of substrates including linen, poly,

vinyl, magnet stock and more

- Superior mixed media, low-density color and mixed color/black

performance

Cost Control

Remote Services ensures market-leading press availability

Longer-life components

Precision automation with the Xerox-exclusive Full Width Array for

critical imaging automation that reduces time and waste

Scalable and modular solutions simplify workflows for one or many

presses

Automated Color Quality Suite delivers consistent, accurate, and

automated color, which reduces waste, cost and time

System / Product Configuration

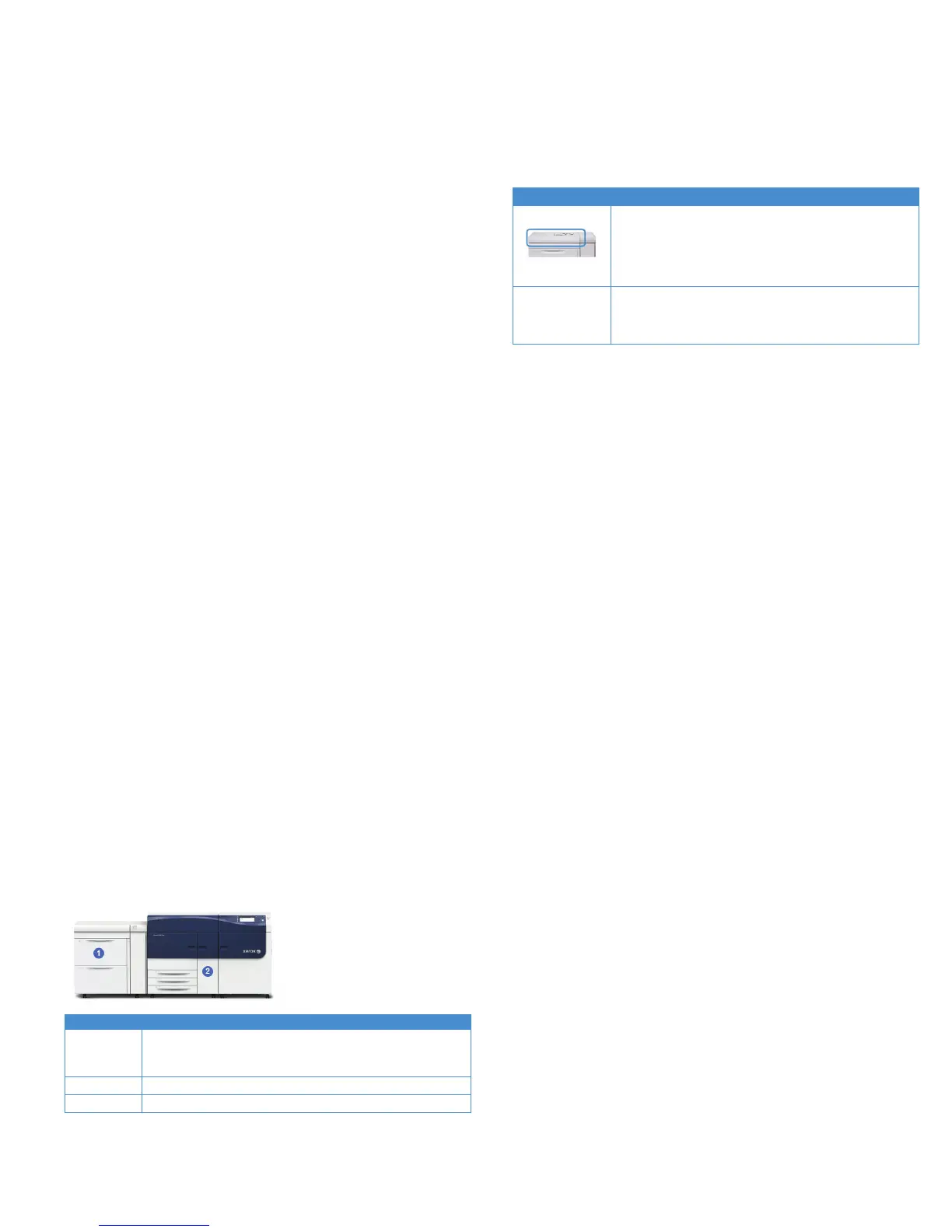

Base Configuration

Feeding

1. 2-Tray Advanced High Capacity Feeder

2. Press with three main trays and embedded control

panel with touch screen

Output

3. (Not shown) Choice of Finishing Options.

Print Server

4. (Not shown) Choice of one of three Print Servers.

Feeding / Finishing Options

Feeding

Bypass/Tray 5

The optional Bypass/Tray 5 mounts on top of the 2-

Tray OHCF

This tray is sometimes called the Multisheet Inserter

(MSI)

Maximum 250 sheet capacity

Dual

Advanced

High Capacity

Feeder

The optional Dual Advanced High Capacity Feeder is

added to the standard 2-Tray OHCF

IMPORTANT: Refer to Configuration Dependencies for information on

configuration requirements for the finishing devices

Loading...

Loading...