*

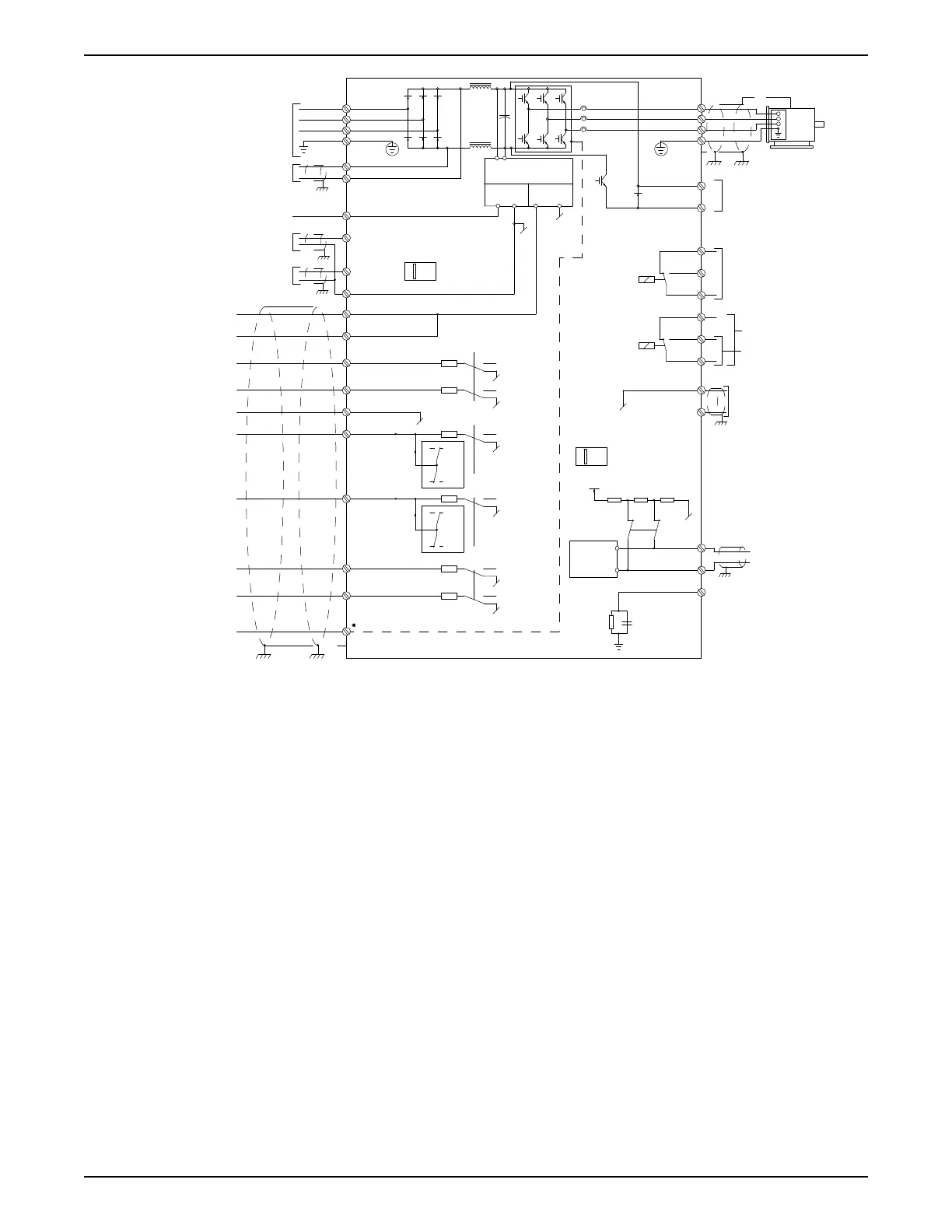

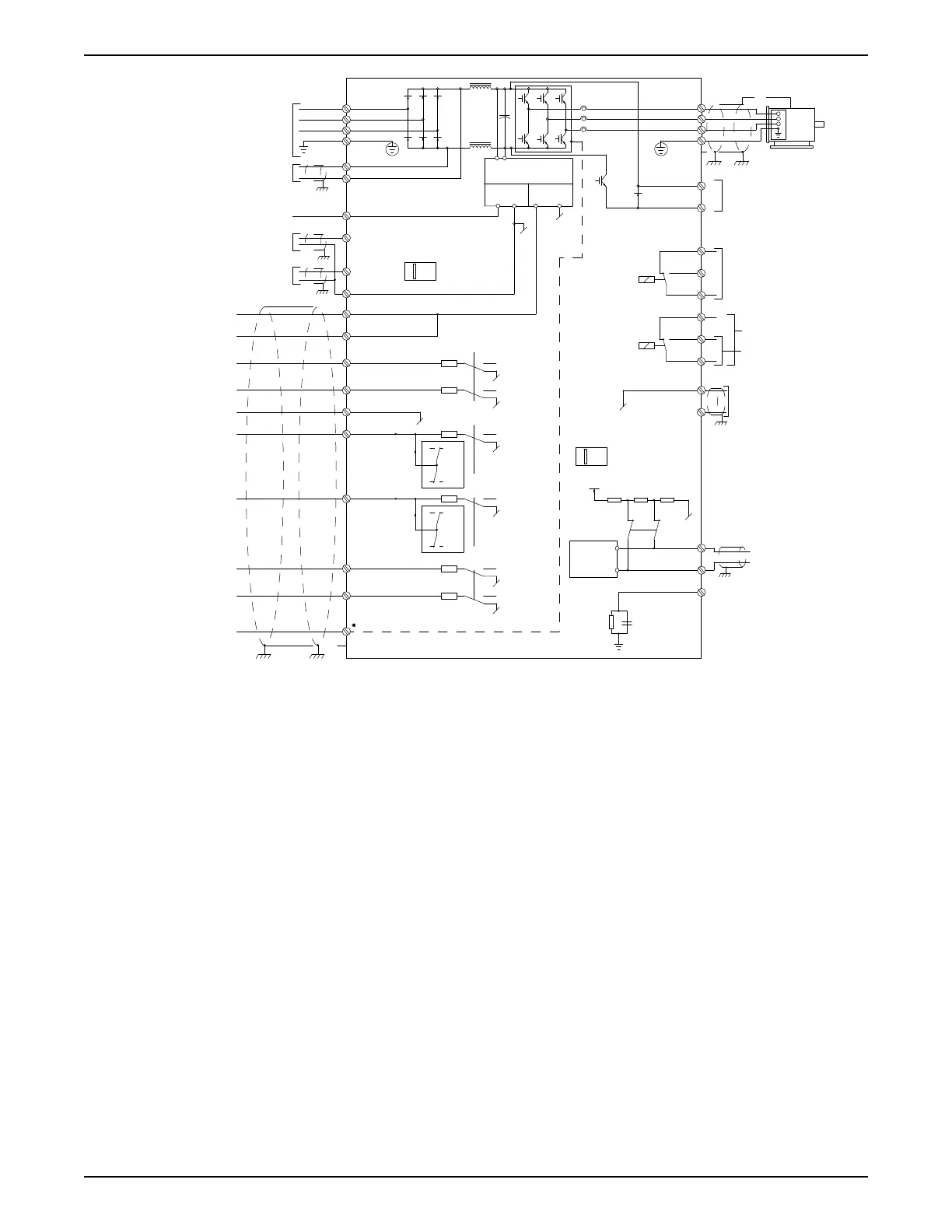

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4–20 mA

12 (+24 V OUT)

13 (+24 V OUT)

18 (D IN)

20 (COM D IN)

15 mA 200 mA

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

0/4–20 mA

03

0–10 V DC

+10 V DC

0/4–20 mA

240 V AC, 2 A

24 V DC

02

01

05

04

06

240 V AC, 2 A

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

19 (D IN)

24 V (NPN)

0 V (PNP)

27

24 V

0 V

(D IN/OUT)

0 V (PNP)

24 V (NPN)

(D IN/OUT)

0 V

24 V

29

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

33 (D IN)

32 (D IN)

ON

2

1

S202

ON=0–20 mA

OFF=0–10 V

95

400 V AC, 2 A

P 5-00

(R+) 82

(R-) 81

37 (D IN)

+ - + -

130BA544.13

(P RS485) 68

(N RS485) 69

(COM RS485) 61

0V

5 V

S801

RS485

RS485

21

ON

S801

3-phase

power

input

DC bus

Switch mode

power supply

Motor

Analog output

Interface

Relay1

Relay2

ON=Terminated

OFF=Open

Brake

resistor

(NPN) = Sink

(PNP) = Source

Figure 47: Basic electrical connection

Terminal 37 is the input to be used for Safe Stop. For instructions on safe stop installation,

refer to the section Safe Stop Installation in the adjustable frequency drive Design Guide.

See also section Safe Stop and Safe Stop Installation.

In rare cases, very long cables and analog signals may, depending on installation, result in

50/60 Hz ground loops due to noise from power line supply cables.

If this occurs, it may be necessary to break the shield or insert a 100 nF capacitor between

shield and chassis.

Digital and analog inputs and outputs

The digital and analog inputs and outputs must be connected to the adjustable frequency

drive common inputs (terminal 20, 55, 39) to avoid ground currents from both groups to

affect other groups. For example, switching on the digital input may disturb the analog

input signal.

5 Electrical Installation

42 Aquavar

®

Intelligent Pump Controller - 150 HP to 600 HP INSTRUCTION MANUAL

Loading...

Loading...