en – Translation of the Original Instructions

e-SV series – Additional Installation, Operation and Maintenance Instructions 37

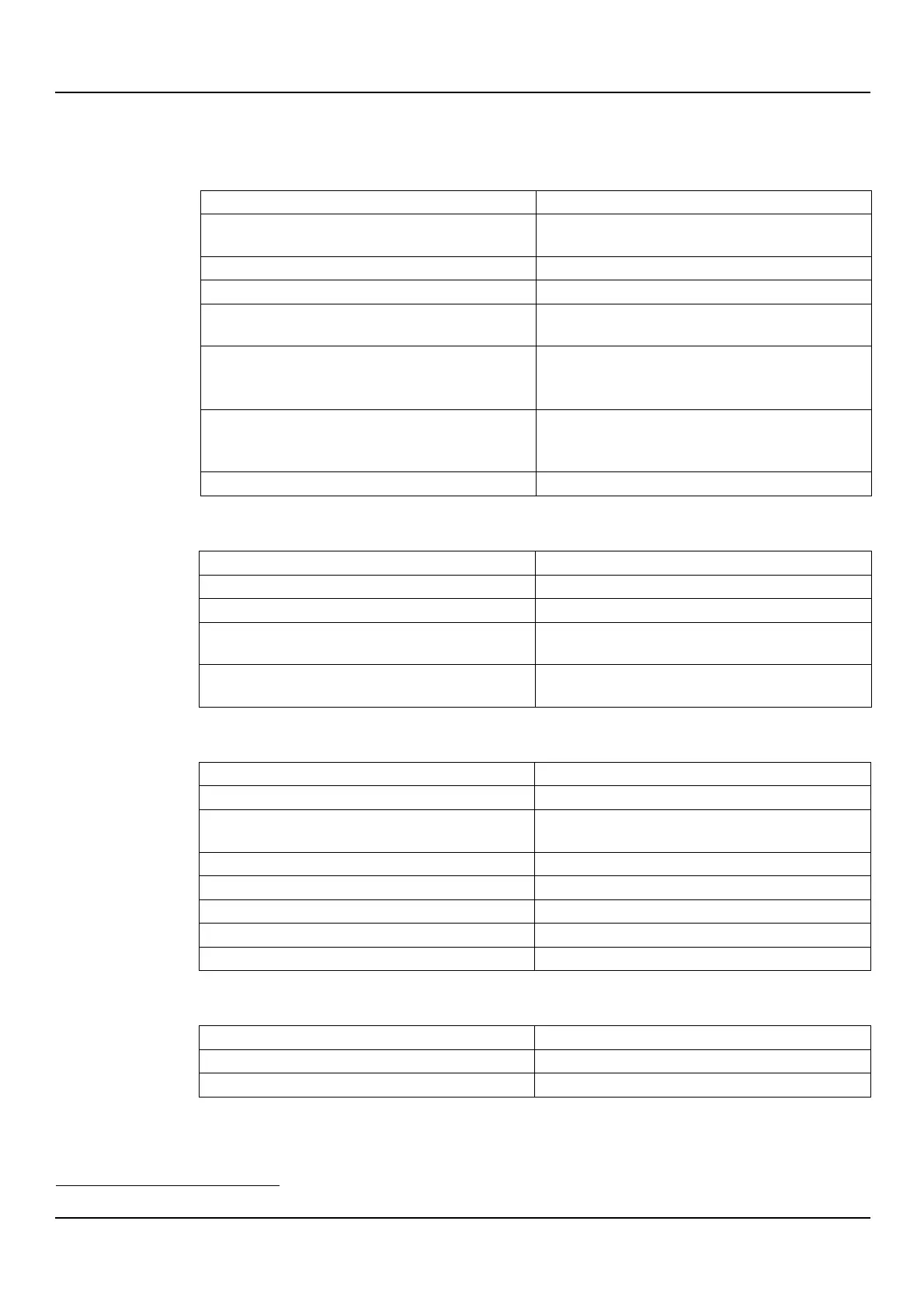

7.5 The thermal overload protection triggers

The motor thermal overload protection triggers occasionally, or after the unit has been

running for a few minutes.

It is calibrated at a value too low in relation to the rated

current of the motor

Input voltage outside the rated limits

Make sure the voltage values are correct

Make sure the voltage of the three phases is balanced

Incorrect working curve (flow rate greater than the maximum

permitted flow rate)

Reduce the required flow rate

Liquid too dense, presence of solid or fibrous substances

(unit overloaded)

Reduce the density of the liquid and/or

•

Remove the solid substances and/or

•

Increase the size of the motor

Room temperature too high, exposure to sunlight

•

Lower the temperature at the point of the thermal

overload protection and/or

•

Protect against direct sunlight

Send the unit to an authorised workshop for testing

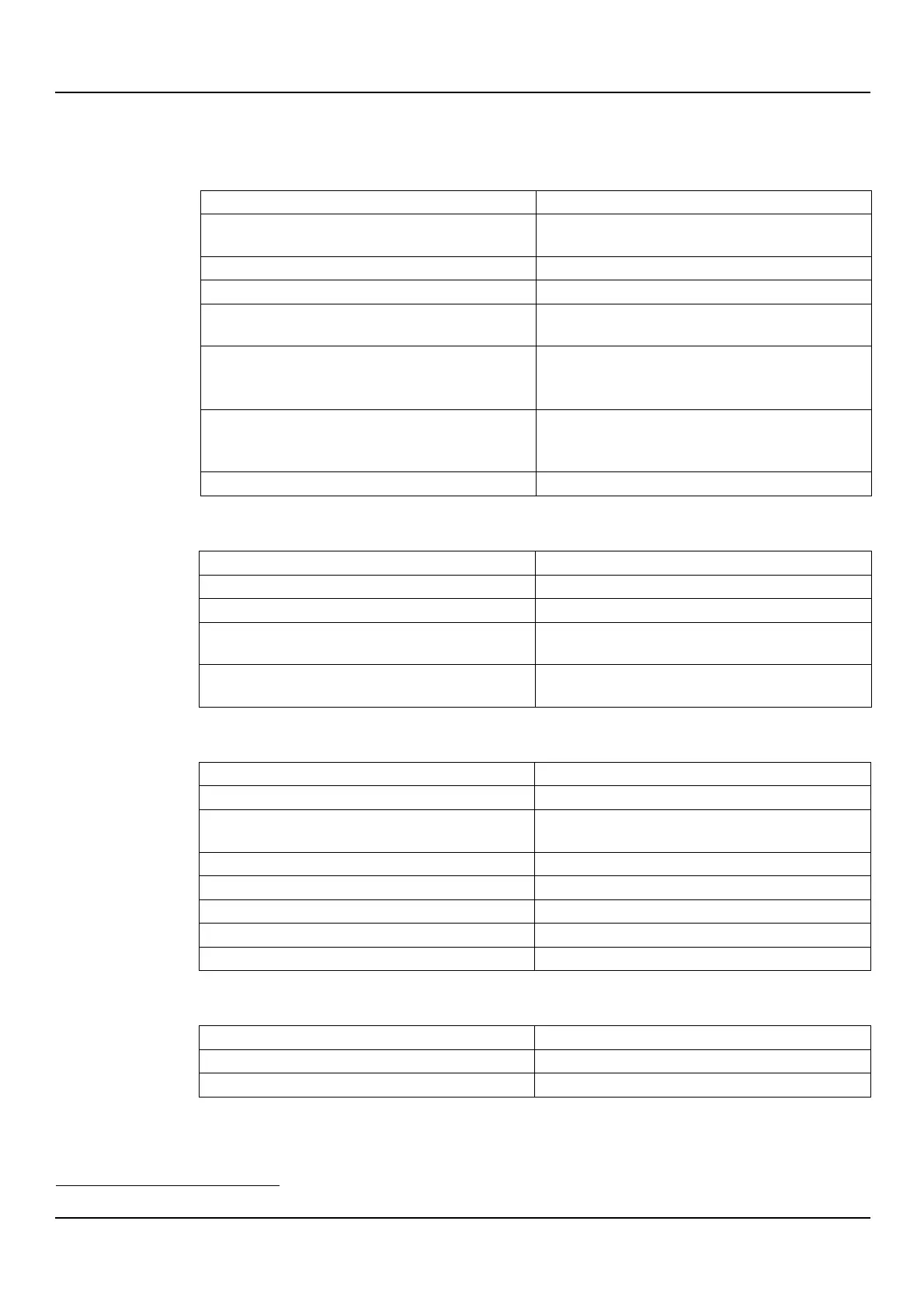

7.6 The motor becomes excessively hot

Room temperature outside the rated limits

Lower the room temperature

Cooling fan of the motor clogged or damaged

Clean or replace the cooling fan

The unit starts up too frequently

See the section: The unit produces excessive noise and/or

vibrations

The frequency converter, if present, has not been calibrated

properly

See the frequency converter manual

7.7 The unit runs but there is little or no flow rate

Motor turns in the wrong direction

Check the direction of rotation and change it if necessary

Incorrect priming (there are air bubbles in the suction pipe or

in the unit)

Repeat the priming procedure

Increase the NPSH

2

available in the system

Check valve locked in closed or partially closed position

Foot check valve locked in closed or partially closed position

Replace the foot check valve

Piping and/or unit clogged

7.8 When switched off, the unit turns in the opposite direction

Replace the foot check valve

2

Net Positive Suction Head

Loading...

Loading...