en – Original instructions

43

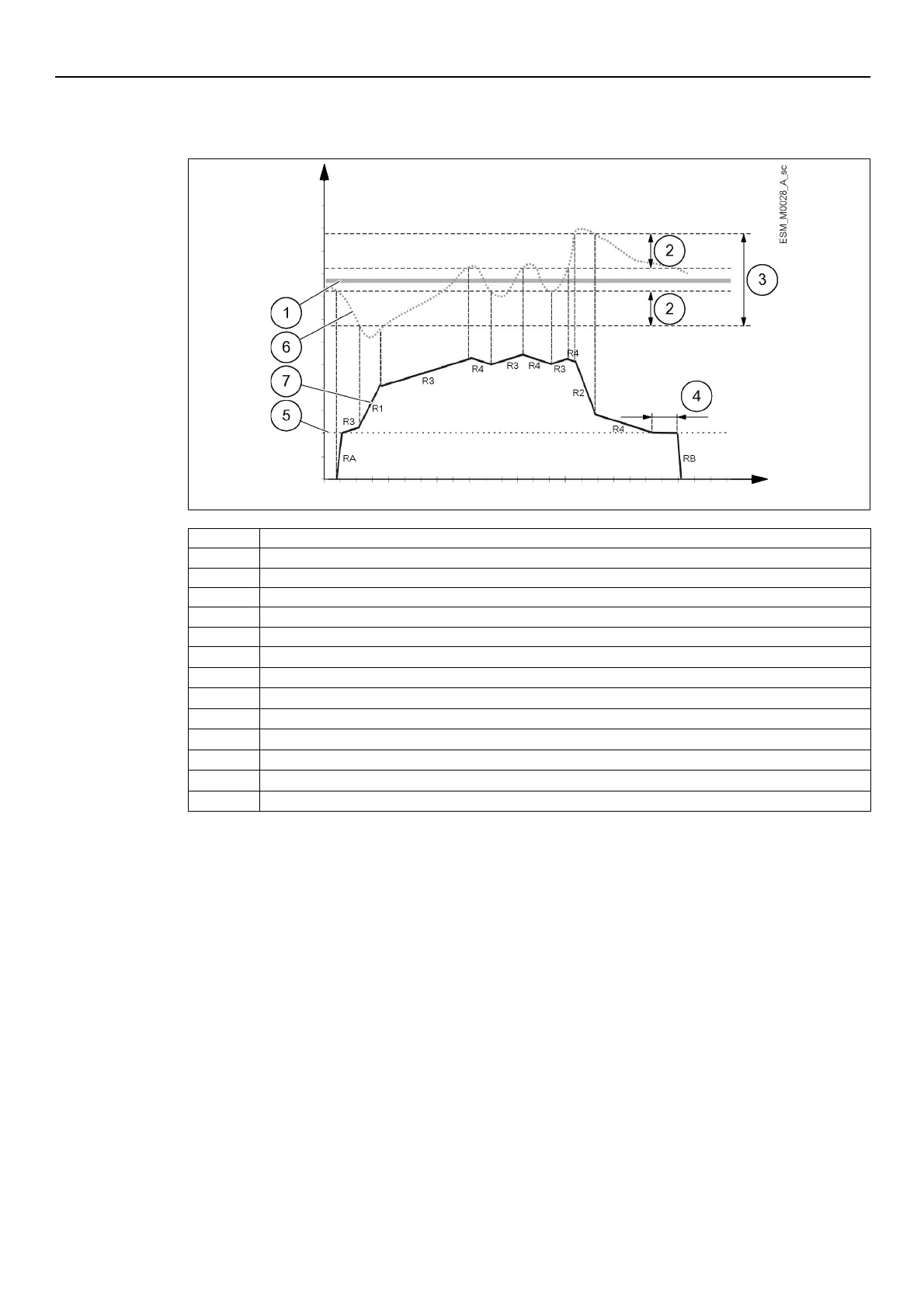

6.6.2 Example: Ramp Settings

The illustration shows the ramp settings.

P37 (Adjustment hysteresis) as a % of P36 (Adjustment window)

P36 (Adjustment window) as a % of P01 (Required Value)

P35 (Minimum speed - Duration)

→

P32 (Acceleration ramp at startup)

→

P32 (Deceleration ramp at shutdown)

→

P28 (Ramp 1) - Fast ramp speed increase

→

P29 (Ramp 2) - Fast ramp speed decrease

→

P30 (Ramp 3) - Slow ramp speed increase

→

P31 (Ramp 4) - Slow ramp speed decrease

For further information on the adjustment of the ramps, see Par. 6.5.3.

6.6.3 Example: Effective Required Value

Pumps activation in cascade modes:

1. Lead pump reaches its P60 (Enable Speed).

2. Actual value falls to the cut in-value of the 1st assist pump.

The 1st assist pump switches on automatically. (Cut-in value = P01 (Required Value) - P59

(Actual Value Decrease))

3. A new required value, P02 (Effective Required Value) is calculated after the start up.

Calculation of Effective Required Value in Cascade Serial (MSE):

K = number of active pumps

Pr = pump priority

P02 (Actual Required Value) = P01 (Required Value) + (K – 1) * P58 (Actual Value Increase) –

(Pr – 1) * P59 (Actual Value Decrease)

Calculation of Effective Required Value in Cascade Synchronous (MSY):

K = number of active pumps (K ≥ Pr)

P02 (Actual Required Value) = P01 (Required Value) + (K – 1) * (P58 – P59)

Loading...

Loading...