Counterweight Replacement

REMOVE

WARNING

The lift truck must be put on blocks for some

types of maintenance and repair. The removal of

the following assemblies will cause large changes

in the center of gravity: mast, drive axle, engine

and transmission, and counterweight. When the

lift truck is put on blocks, put additional blocks in

the following positions to maintain stability:

• Before removing the mast and drive axle,

put blocks under the counterweight so the

lift truck cannot fall backward.

• Before removing the counterweight, put

blocks under the mast assembly so the lift

truck cannot fall forward.

The surface must be solid, even, and level when

the lift truck is put on blocks. Make sure that any

blocks used to support the lift truck are solid,

one-piece units. See the Operating Manual or Peri-

odic Maintenance 8000YRM1774.

WARNING

DO NOT operate the lift truck if the capscrew for

the counterweight is not installed. When the cap-

screw is removed, the counterweight can fall from

the lift truck.

WARNING

LPG can cause an explosion. DO NOT cause

sparks or permit flammable material near the LPG

system. LPG fuel systems can be disconnected

indoors only if the lift truck is at least 8 m (26 ft)

from any open flame, motor vehicles, electrical

equipment, or ignition source.

Close the shutoff valve on the LPG tank before

any part of the engine fuel system is disconnec-

ted. Run the engine until the fuel in the system is

used and the engine stops.

If the engine will not run, close the shutoff valve

on the LPG tank. Loosen the fitting on the supply

hose from the LPG tank where it enters the filter

unit. Permit the pressure in the fuel system to de-

crease slowly. Fuel leaving the fitting removes

heat. Use a cloth to protect your hands from the

cold fitting.

NOTE: The counterweight is held in position on the

frame by two hooks that are part of the frame. One

M24 × 3 × 110 capscrew holds the counterweight to

the lower part of the frame on lift truck models See

Figure 16.

NOTE: Perform Step 1 for lift trucks equipped with

LPG.

1. Use the procedures in Fuel System PSI 2.4L

0900YRM1757 to remove the LPG tank and

bracket so that the counterweight can be re-

moved.

Additional information on the LPG fuel system can

be found in Fuel System PSI 2.4L 0900YRM1757.

WARNING

The counterweight is heavy. Make sure that the

eyebolts and lifting devices have enough capacity

to lift the weight. The approximate weights of the

counterweight castings are shown in Table 1.

2. Install washers, lifting eyebolts, and nuts into lift

holes of the counterweight. See Figure 17. Con-

nect a crane to the lifting eyebolts and raise the

crane until it holds part of the weight of the coun-

terweight.

3. Remove the tow pin from counterweight.

4. Remove the capscrew from counterweight and

frame. See Figure 16 and Figure 17. Use the

crane to lift the counterweight from the lift truck.

Put counterweight on the floor so that it has stabil-

ity and will not fall over. Take care not to damage

exhaust or cooling system components.

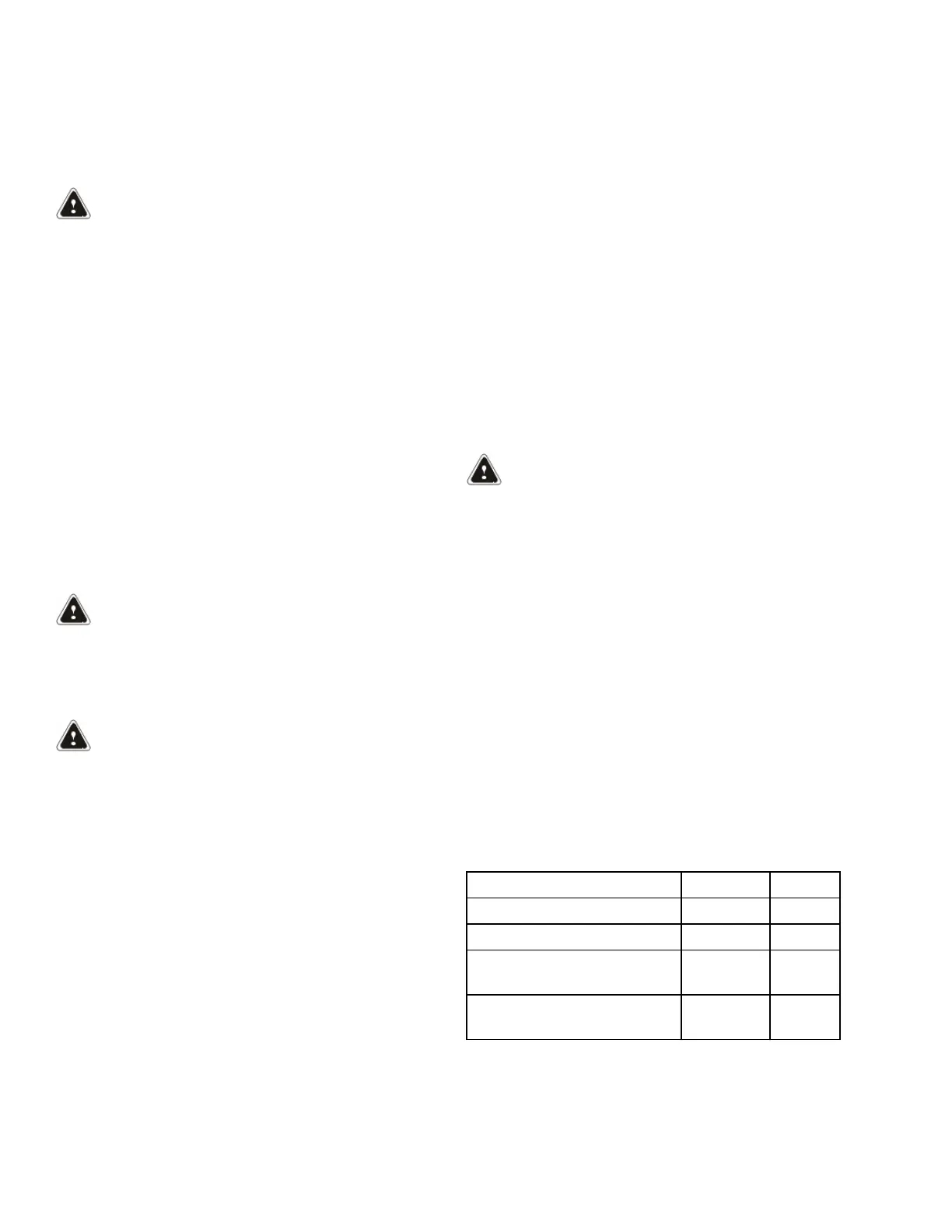

Table 1. Weight of Counterweights

Model kg lb

GLC050LX (B967) 1401 3088

GLP/GDP20LX (B974) 950 2094

GLP/GDP25LX (GLP/

GDP050LX) (B974)

1230 2712

GLP/GDP25LX (GLP/

GDP050LX) (B974)

1335 2943

Counterweight Replacement 0100 YRM 1766

16

Loading...

Loading...