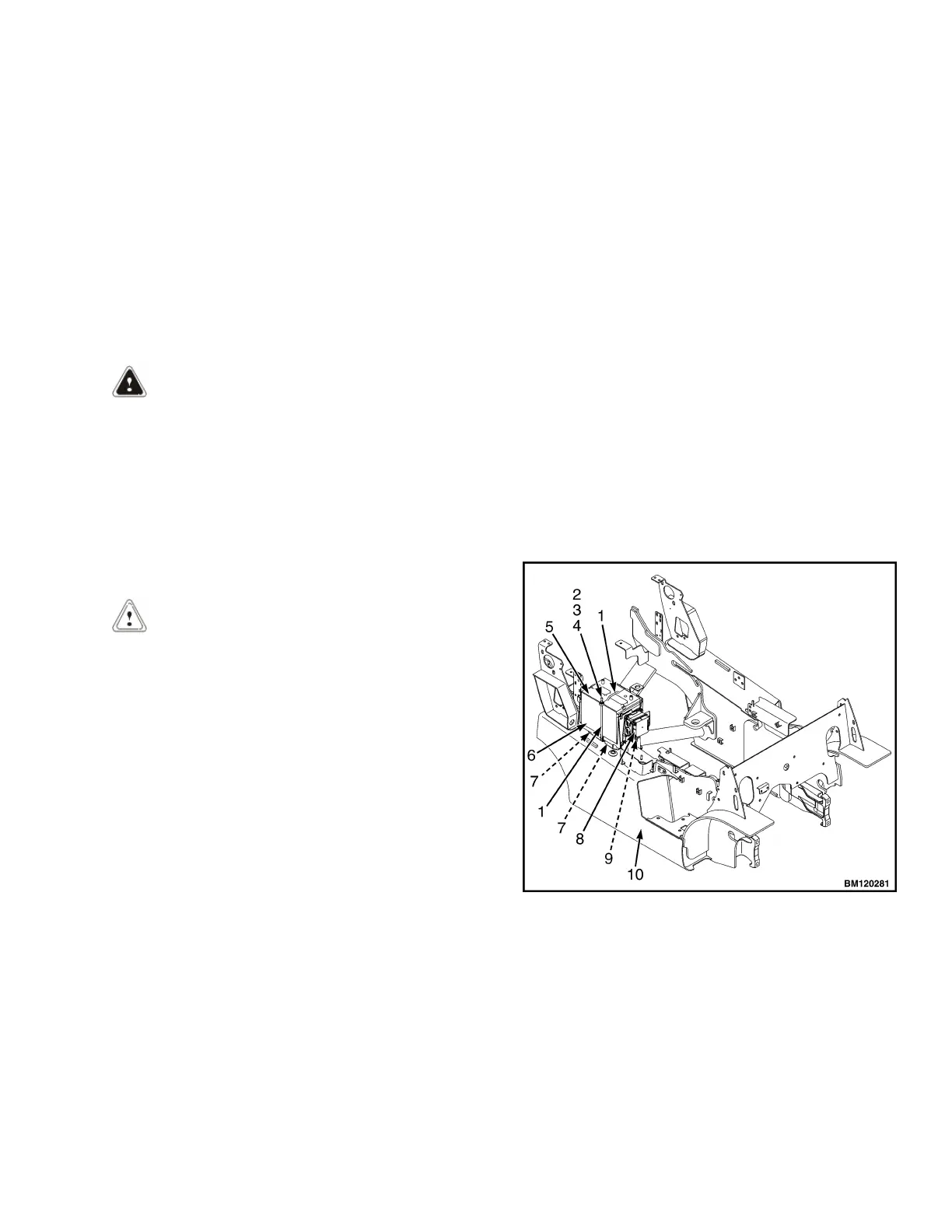

Legend for Figure 22

A. TOP VIEW B. LEFT VIEW

1. AIR FILTER AND BRACKET ASSEMBLY

2. AIR FILTER HOSE

3. SHROUD

4. RADIATOR CAP

5. COOLANT HOSES

6. NEGATIVE BATTERY CABLE

7. BATTERY AND BATTERY TRAY

8. POSITIVE BATTERY CABLE

9. PDM

10. ENGINE HARNESS CONNECTOR

11. HYDRAULIC RETURN HOSE

12. CHASSIS HARNESS

13. TRANSMISSION MOUNT

14. TRANSMISSION OIL COOLER LINES

15. LPG REGULATOR CONNECTOR

16. HYDRAULIC SUPPLY HOSE

17. EXHAUSTS PIPE TO EXHAUST MANIFOLD

18. LOWER RADIATOR HOSE

19. FAN

20. FAN PULLEY AND FAN SPACER

21. FUEL LINE

WARNING

DO NOT remove the radiator cap from the radiator

when the engine is hot. When the radiator cap is

removed, the pressure is released from the sys-

tem. If the system is hot, the steam and boiling

coolant can cause burns.

5. Let coolant cool to ambient temperature. Place a

drain pan with a capacity greater than the ca-

pacity of the cooling system under radiator. Re-

move radiator cap.

CAUTION

Disposal of lubricants and fluids must meet local

environmental regulations.

6. Open the drain plug or disconnect the bottom ra-

diator hose to drain coolant from radiator and en-

gine. See Figure 22.

7. Remove the hood and seat combination and rear

side covers. See section Hood, Seat, and Side

Covers Replacement for procedures.

8. Disconnect the ground strap from the frame and

remove the power distribution module (PDM) from

the battery tray. See Figure 23.

9. Remove battery and battery tray from lift truck as

described in the steps below:

a. Remove cap, flange nut, and lockwasher from

battery lockdown bar. See Figure 23.

b. Disengage battery lockdown bars and remove

bar from top of battery. See Figure 23.

c. Remove battery from battery tray. See Fig-

ure 23.

d. Remove three capscrews and battery tray from

frame. See Figure 23.

10. Disconnect the remaining coolant hoses from the

radiator and cap them to prevent leakage. See

Figure 22.

11. Remove the radiator fan pulley, shroud, and fan

assembly. See Cooling System - PSI 2.4L En-

gine 0700YRM1767 for the removal procedures.

1. BATTERY LOCKDOWN BAR

2. CAP

3. FLANGE NUT

4. LOCKWASHER

5. BATTERY

6. BATTERY TRAY

7. CAPSCREW

8. PDM

9. GROUND STRAP

10. FRAME

Figure 23. Power Distribution Module and Battery

Tray

0100 YRM 1766 Engine Replacement

25

Loading...

Loading...