1. FEELER GAUGE

Figure 11. Valve Clearance Measurement

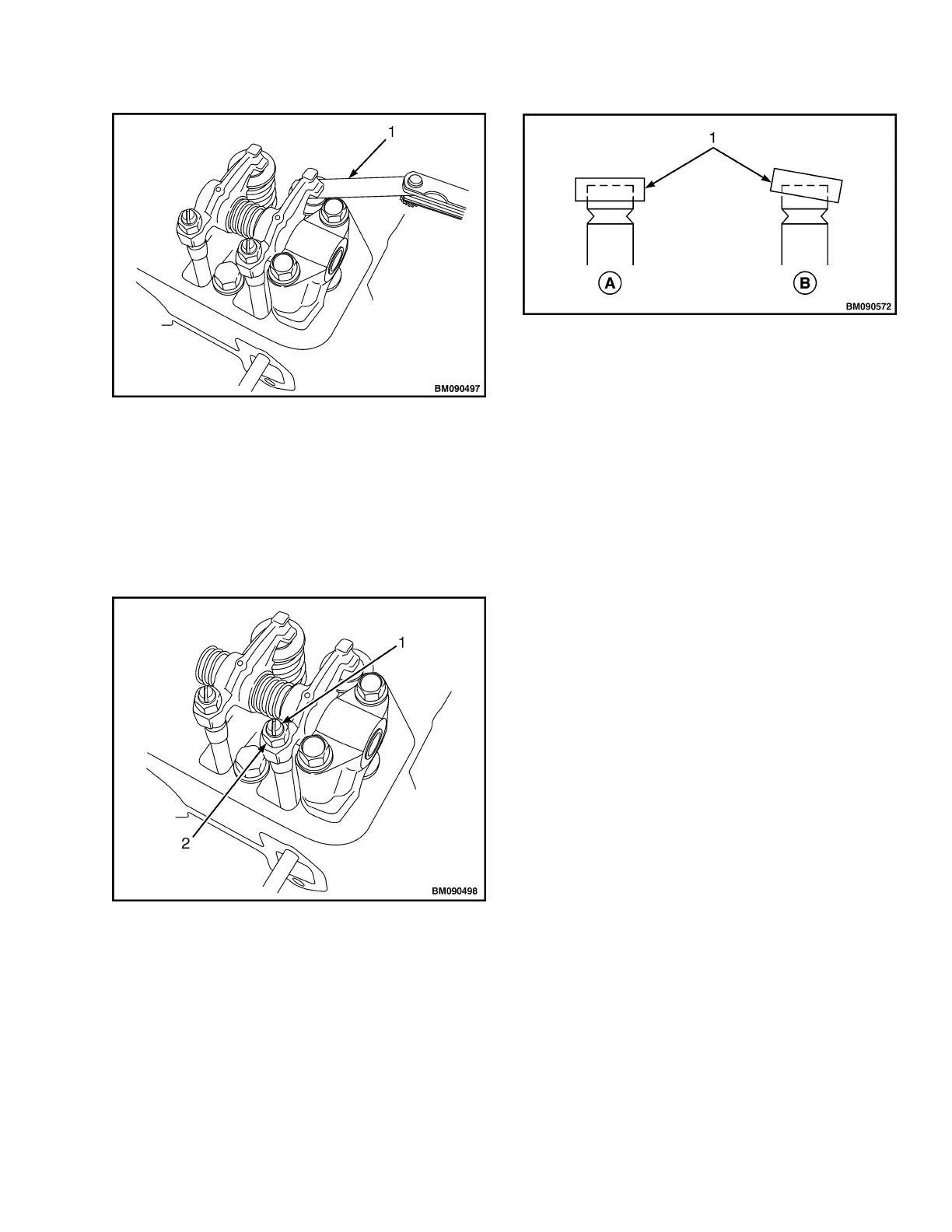

4. If adjustment is needed, loosen the valve adjust-

ing screw lock nut and valve adjusting screw on

the rocker arm (see Figure 12) and check the

valve for any inclination of valve cap, entrance of

dirt, or wear. See Figure 13.

1. VALVE ADJUSTING SCREW

2. VALVE ADJUSTING SCREW LOCK NUT

Figure 12. Valve Clearance Adjustment

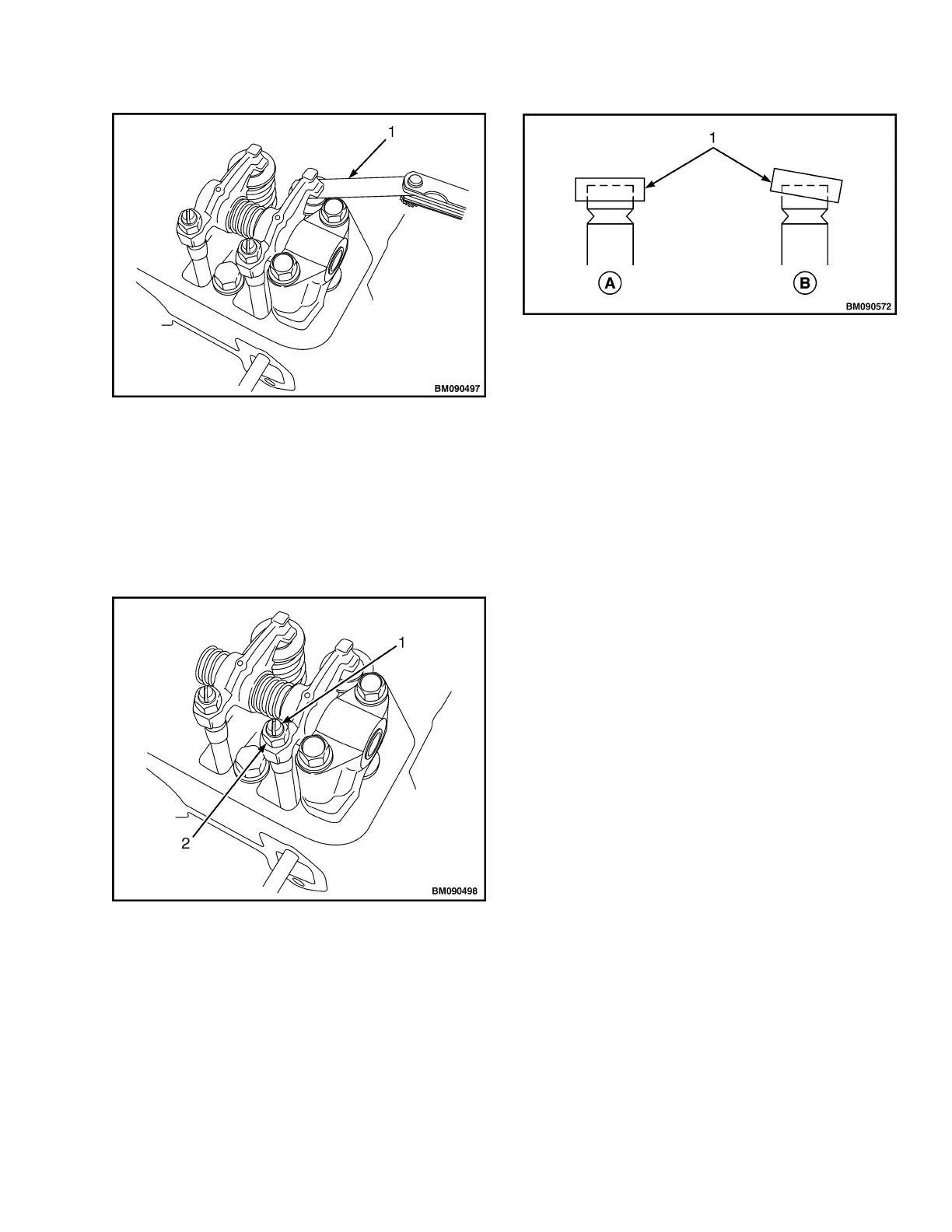

A. NORMAL B. ABNORMAL

1. VALVE CAP

Figure 13. Valve Cap Check

NOTE: There is a tendency for the clearance to de-

crease slightly when the lock nut is tightened. It is

suggested that you make the clearance adjustment

slightly on the loose side before tightening the lock

nut.

5. Insert a 0.2 mm (0.008 in.) feeler gauge between

the rocker arm and valve cap and adjust the

clearance so there is a slight drag on the feeler

gauge when sliding it between the rocker arm and

valve cap. Tighten the valve adjusting screw lock

nut and recheck the clearance. The valve clear-

ance should be between 0.15 to 0.25 mm (0.006

to 0.010 in.).

6. Apply clean engine oil to the contact surface be-

tween the adjusting screw and push rod.

7. Turn the crankshaft 180 degrees and make the

measurement and adjustment for the number

three cylinder. Then turn the crankshaft 180 de-

grees and make the measurement and adjust-

ment for the number four cylinder. Then turn the

crankshaft 180 degrees and make the measure-

ment and adjustment for the number 2 cylinder.

8. Install the valve cover. See Valve CoverInstall.

0600 YRM 1205 Cylinder Head Assembly Repair

11

Loading...

Loading...