Clean and Inspect

WARNING

Cleaning solvents can be flammable and toxic and

can cause skin irritation. When using cleaning

solvents, always follow the recommendations of

the manufacturer.

WARNING

Compressed air can move particles so that they

cause injury to the user or to other personnel.

Make sure that the path of the compressed air is

away from all personnel. Wear protective goggles

or a face shield to prevent injury to the eyes.

Clean all parts in cleaning solvent. Dry the parts with

compressed air. Inspect for wear, cracks, and any

other damage. Replace all parts as needed.

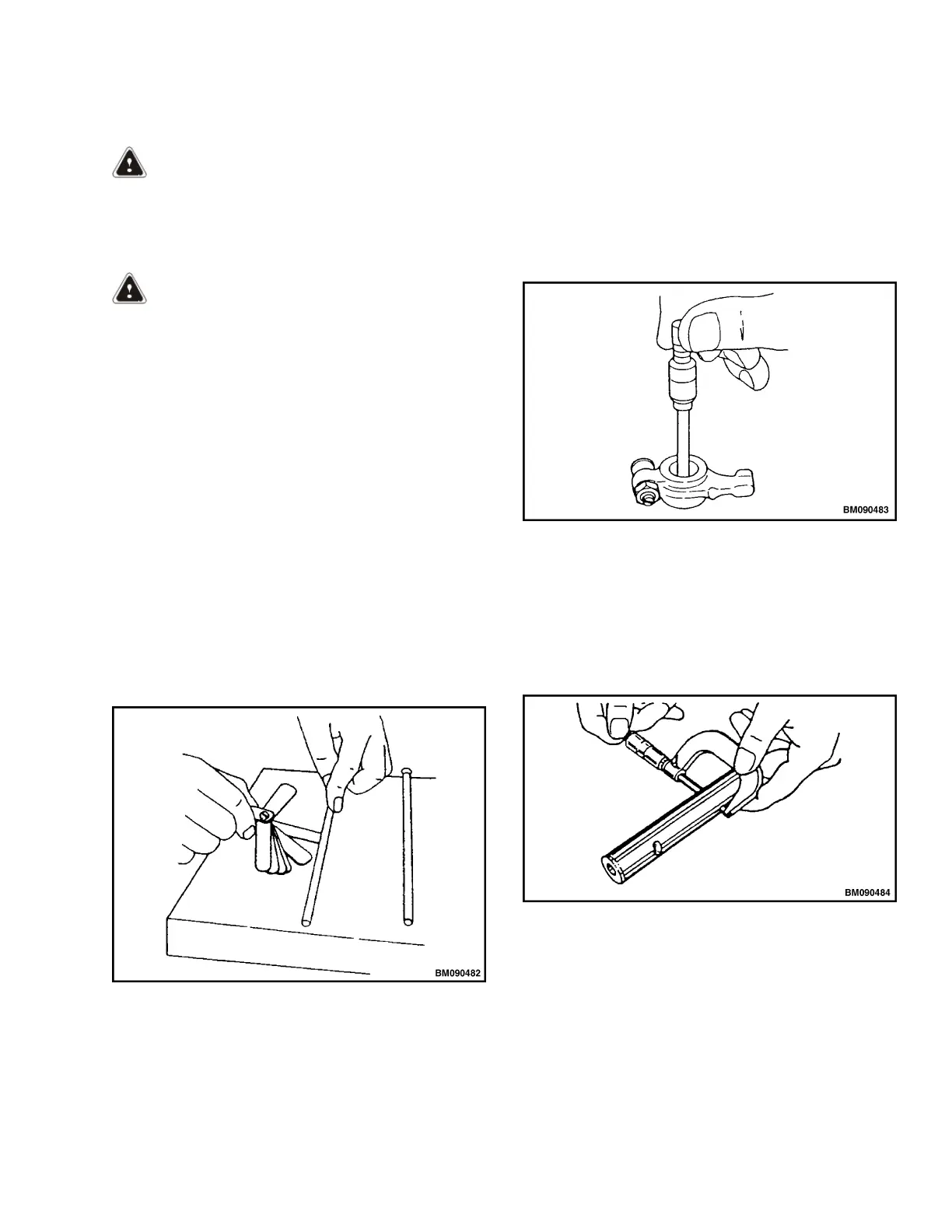

Push Rods

1. Place the push rods on a flat inspection block.

2. Roll the push rods until a gap can be observed

between a portion of the push rod and the surface

of the inspection block.

3. Use a feeler gauge to measure the gap. Refer to

the Engine Specifications for the service limit. See

Figure 8.

Figure 8. Push Rod Inspection

Rocker Arm Assembly

Rocker Arm and Support Bracket Inside Diameter

- Use a test indicator and micrometer to determine if

the inside diameter of all the rocker arm support

brackets and rocker arms are within limits. Refer to

the Engine Specifications for the service limit. See

Figure 9.

Figure 9. Rocker Arm Inside Diameter

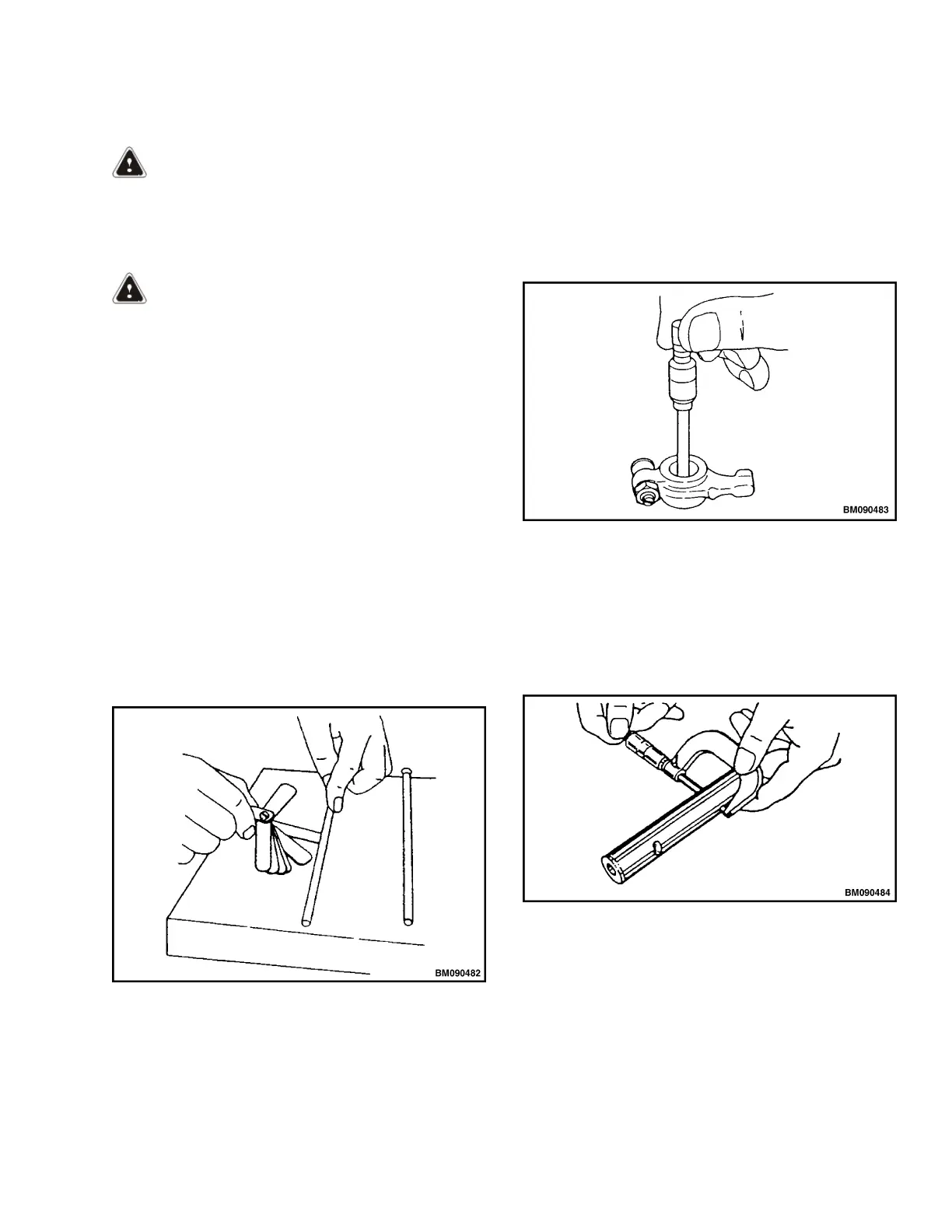

Shaft Outside Diameter - Use a micrometer to

measure the rocker arm shaft outside diameter. Refer

to the Engine Specifications for the service limit. See

Figure 10.

Figure 10. Rocker Arm Shaft Outside Diameter

0600 YRM 1205 Cylinder Head Assembly Repair

9

Loading...

Loading...