12. Disconnect engine wiring harness connectors

from proportional valve connectors, transducer

connectors, solenoid valve connector, tempera-

ture sensor connector, and transmission. See Fig-

ure 32.

13. Use the access port on the side of engine and re-

move four bolts attaching flywheel to torque con-

verter. See Figure 33.

14. Connect lifting device to engine. Put a block un-

der transmission housing to support transmission.

15. Remove four flange bolts from torque converter

housing and flywheel housing on transmission

side. See Figure 34.

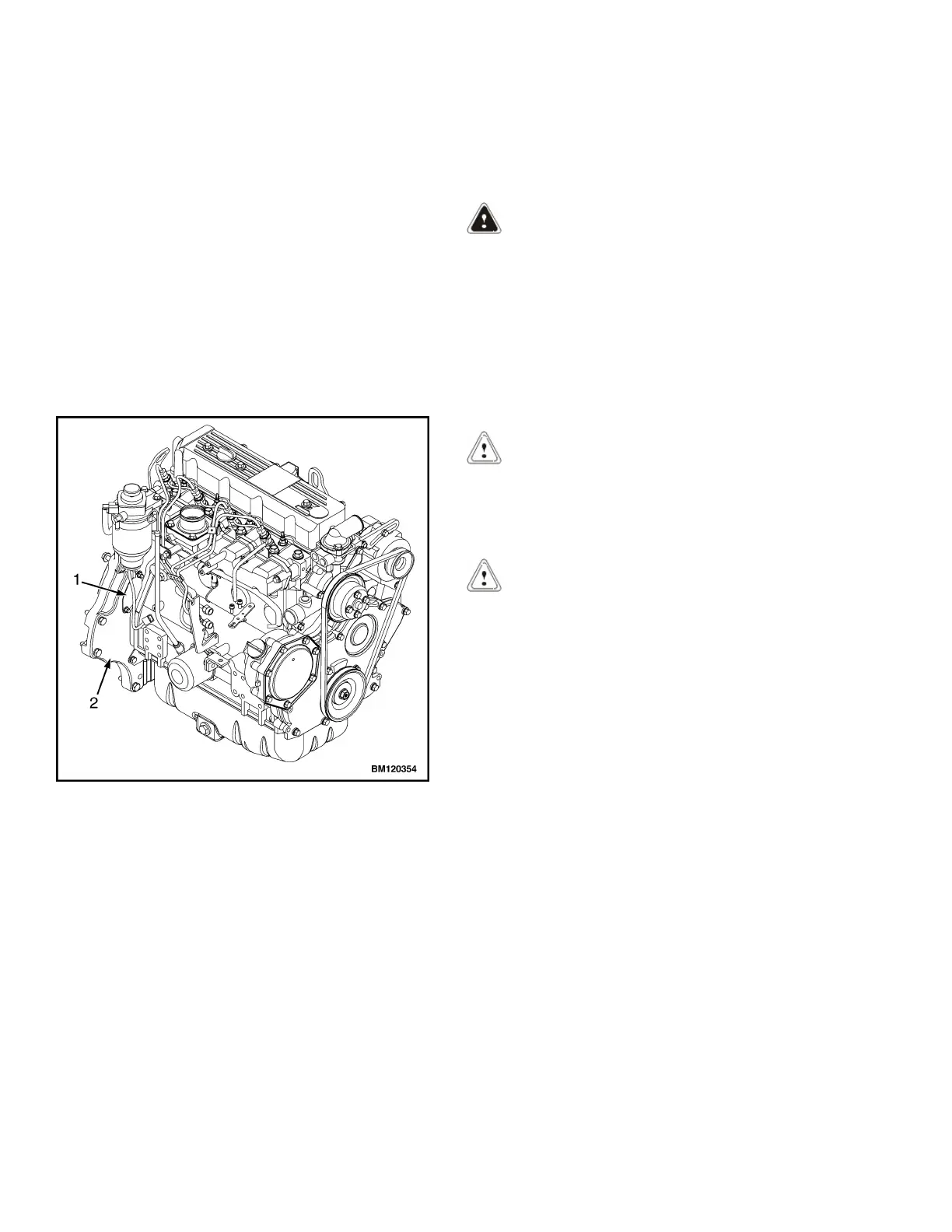

1. ACCESS PORT

2. FLYWHEEL HOUSING

Figure 33. Yanmar Torque Converter Bolt Access

16. Remove six hex head capscrews and six lock-

washers from flywheel housing and torque con-

verter housing on flywheel housing side. See Fig-

ure 34.

WARNING

The engine is heavy. Make sure that any lifting de-

vice has enough capacity to lift the engine.

The engine can weigh approximately

194 kg (428 lb).

17. Remove flange locknuts, washers, snubbing

washers, capscrews, and isolators from the en-

gine mounts. Remove engine adapter to transmis-

sion bolts, if equipped. See Figure 35.

CAUTION

When separating the engine away from the trans-

mission, place a piece of plywood in front of radi-

ator. This will keep the engine from damaging the

radiator.

CAUTION

Keep the engine level when the engine is separa-

ted from the transmission so the drive plate is not

damaged.

18. Use a lifting device to carefully move engine away

from torque converter. Make sure all hoses, wires,

and cables are disconnected from the engine,

then lift the engine from the frame and place en-

gine on blocks.

19. Remove torque converter from torque converter

housing.

Engine Replacement 0100 YRM 1766

34

Loading...

Loading...