9 Maintenance and Inspection

MS80W Manipulator 9.1 Inspection Schedule

9-2

159328-1CD

HW1480497

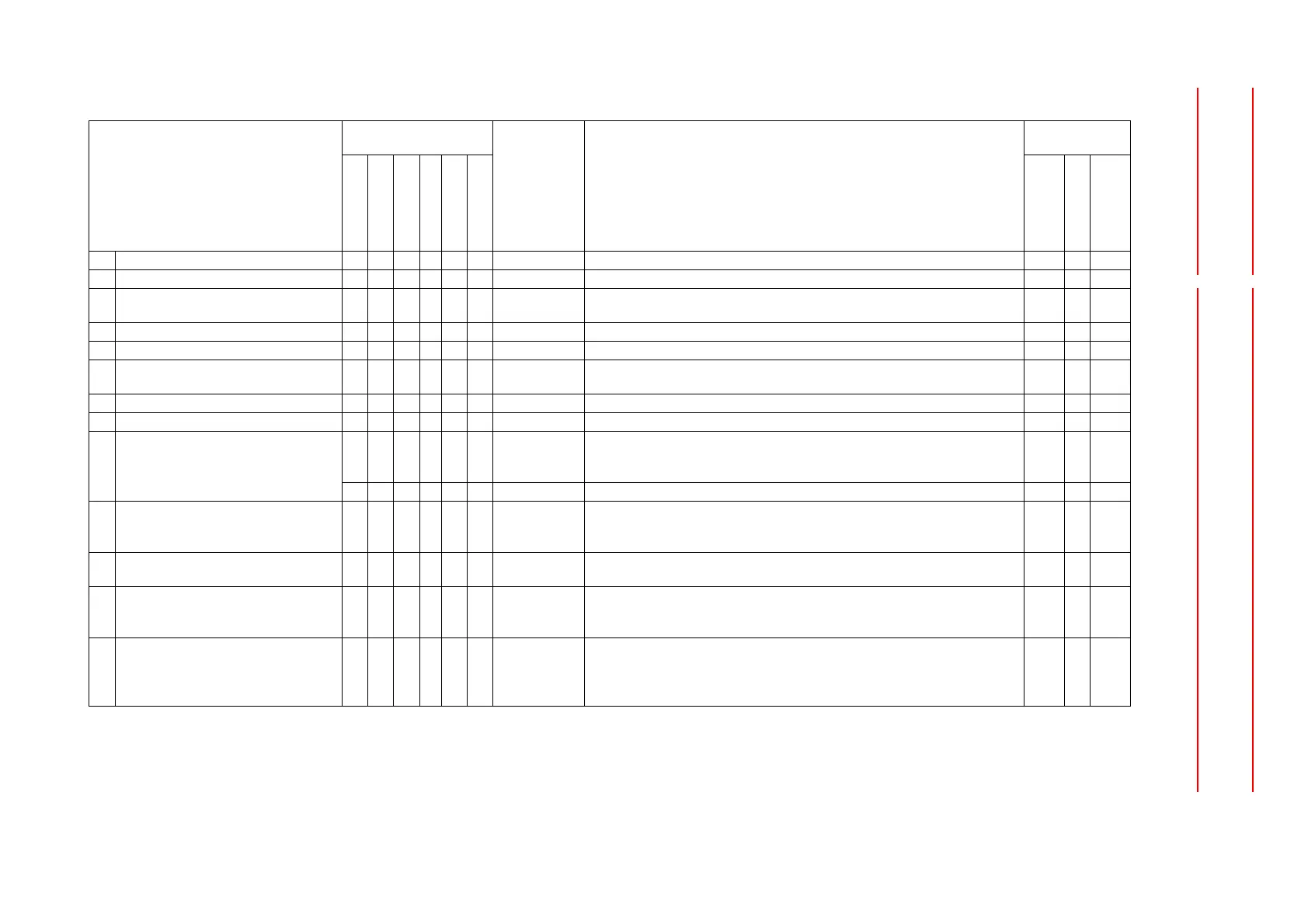

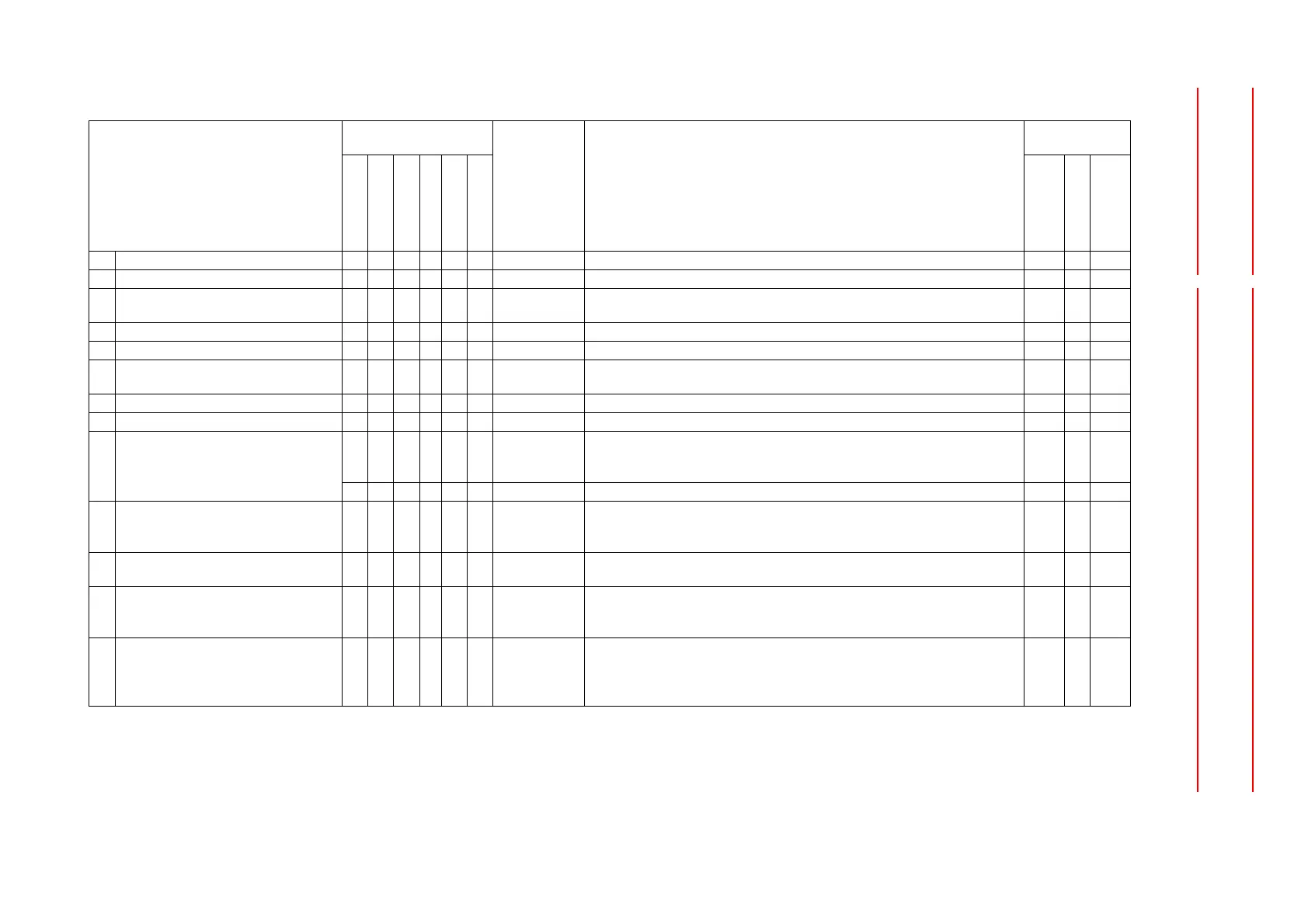

Table 9-1: Inspection Items (Sheet 1 of 2)

Items

1)

Schedule Method Operation Inspection

Charge

Daily

1000HCycle

6000HCycle

12000HCycle

24000HCycle

36000HCycle

Specified

Personnel

Licensee

Service

Company

1 Alignment marks

•

Visual Check alignment mark accordance and damage at the home position.

•••

2 External cables

•

Visual Check for damage and deterioration.

•••

3 Working area and whole exterior of

manipulator

•

Visual Clean the work area if dust or spatter is present.

Check for damage and outside cracks.

•••

4 SLURBT-axes motors

•

Visual Check for grease leakage.

2)

•••

5 Baseplate mounting bolts

•

Wrench Tighten loose bolts. Replace if necessary.

•••

6 Cover mounting screws

•

Screwdriver,

Wrench

Tighten loose bolts. Replace if necessary.

•••

7 SLURBT-axes motor connectors

•

Manual Check for loose connectors and tighten if necessary.

•••

8 Connector base

•

Manual Check for loose connectors.

•••

9 Wire harness in manipulator

•

Visual,

Multimeter

Check for conduction between the main connector of base and

intermediate connector by manually shaking the wire.

Check for wear of protective spring.

3)

••

•

Replace at 2400H inspection

••

10 Limit switches and dogs

(For SLU-axes)

•

Screwdriver,

Wrench,

Multimeter

Check for dirt, damage, malfunction.

Tighten loose bolts.

••

11 Battery pack in manipulator

•

Replace the battery pack when the battery alarm occurs or when the

manipulator has been operated for 36000H.

••

12 S-axis speed reducer

••

Grease Gun Check for malfunction. (Replace if necessary.)

4)

Supply grease.

5)

(6000H cycle).

Exchange grease.

5)

(12000H cycle). See Section 9.3.1.

••

13 LU-axes speed reducers

••

Grease Gun Check for malfunction. (Replace if necessary.)

4)

Supply grease.

5)

(6000H cycle).

Exchange grease.

5)

(12000H cycle).

See Section 9.3.2 and Section 9.3.3.

••

Loading...

Loading...