<4. Operation>

4-4

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

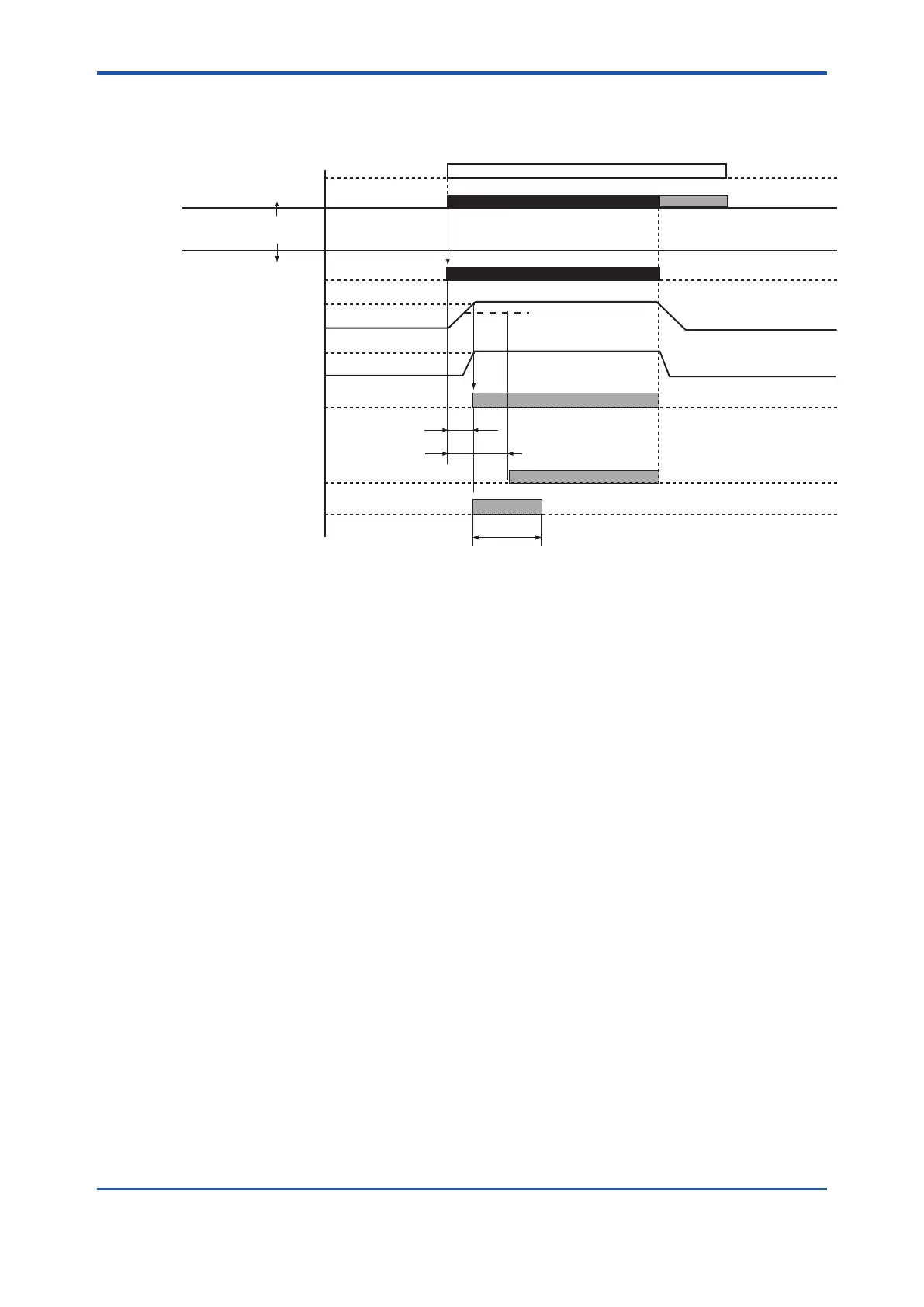

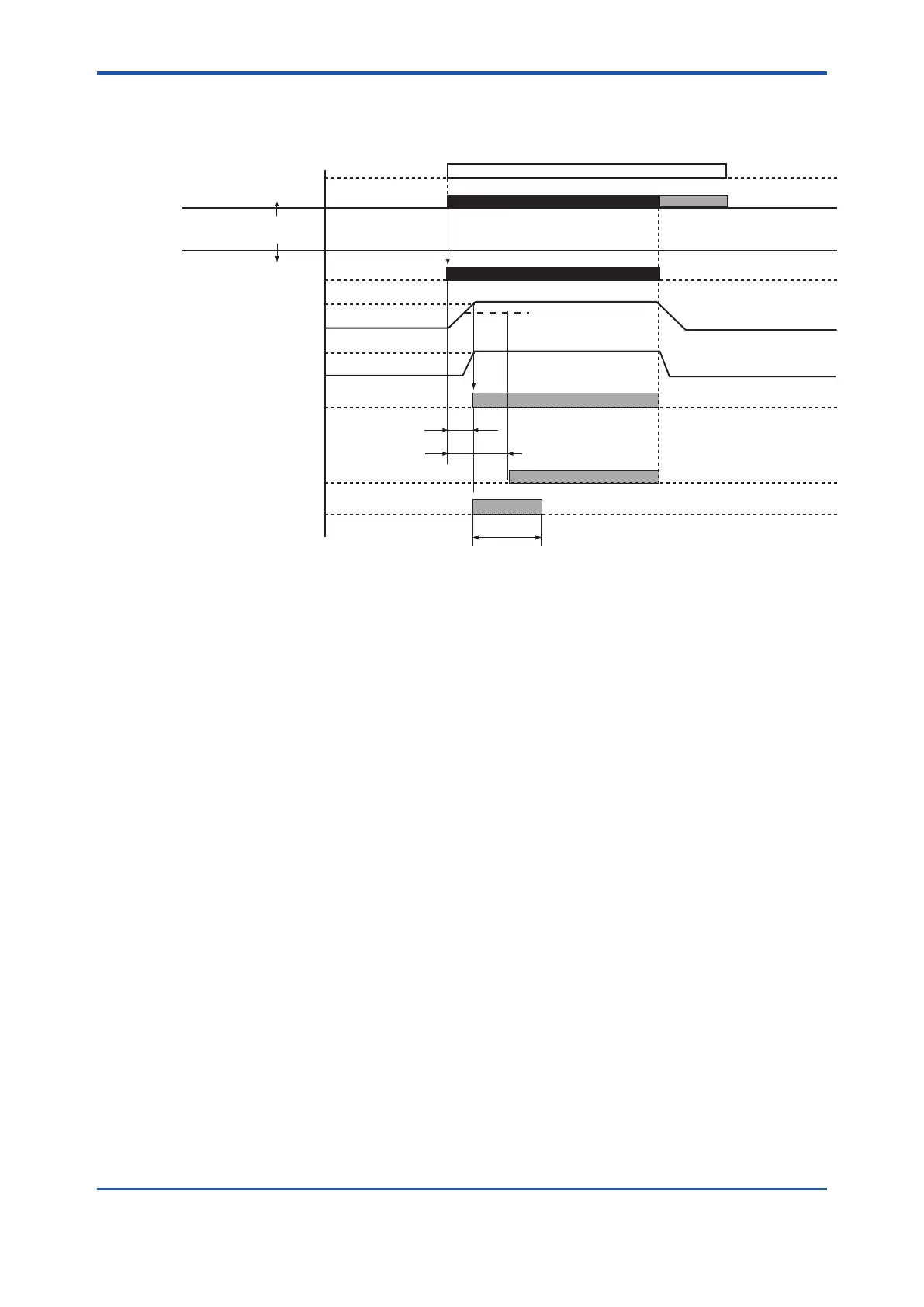

4.2.3 Wash Sequence

Figure 4.4 shows the actions that the system implements to clean the electrodes when

it receives a WASH (cleaning) command from either PH450G or FLXA202/FLXA21.

t2

t1≥

t1<

Holding of pH output signal

WASH

pH meter

Chemical cleaning system

SV2 solenoid valve for

actuating cylinder

Sensor holder

Highest position

Lowest position

Bottom plate of

cleaning chamber

Closes

Opens

DETECT UPPER LIMIT

signal

CYLINDER FAIL signal

SV1 solenoid valve for

forced feeding of chemical

solution and air bubbling

(Measurement mode) (Measurement mode)

(WASH mode)

WASH

Relaxation

Air is injected to raise the cylinder

Open (air is fed to the metering tank.)

t1: Setting of timer T1 t2: Setting of timer T2

When can not reach

the highest position.

Contact signal

for WASH

Figure 4.4 WASH Sequence

l Output of WASH (cleaning) signal

When the setting the interval between WASH (in pH/ORP Converter or 2-Wire Analyzer ) times

out, the system enters the WASH sequence. The WASH signal is then output to the control box

of the operating unit in the chemical cleaning system for the period equivalent to the value set in

the timer.

l Actuation of SV2 solenoid valve

The SV2 solenoid valve in the control box is active while it is receiving the WASH signal. This

causes a pneumatic pressure to be applied to the port that raises the cylinder on the PH8HS3

holder. Consequently, the sensor holder goes up in conjunction with the cylinder slider.

l Output of DETECT UPPER LIMIT signal and CYLINDER FAIL signal

When the sensor holder reaches the upper limit, the bottom plate of the cleaning chamber closes

and the limit switch is turned on. The ON signal from the limit switch then starts timer T2 in the

control box, causing solenoid valve SV1 to be actuated (the valve is opened). Solenoid valve

SV1, when opened, causes a pneumatic pressure to be applied to the interior of the metering

tank, resulting in an approximately 100 ml of the chemical solution being forced into the cleaning

chamber of the holder. The air is kept supplied until timer T2 times out, bubbling the chemical

solution within the cleaning chamber to enhance the cleaning of the pH sensor electrodes.

Note that if the sensor holder does not reach the upper limit when timer T1, which starts at the

same time the WASH signal is output, is timed out, the CYLINDER FAIL signal is given. This

signal stops (the contact opens) when the WASH contact signal is no longer present.

Loading...

Loading...