<6. Troubleshooting>

6-3

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

(4) Put a new spring in place. Also replace the washer, spring-adjustment nut, locknut and

guide plate removed in step (3) as well as the screw removed in step (2).

(5) Taking precautions against problems in vertical movement of the rod, secure the guide plate

to the chassis (with screws).

(6) Adjust the pressure of the spring.

First, x the bottom plate of the cleaning chamber (temporarily with tape) to where the

gasket makes slight contact with the bottom edge of the chamber.

Next, screw the spring-adjustment nut into the rod so the spring tightens as it contracts by

approximately 9 mm (pressure of spring: approximately 40 N {4 kgf}).

(7) Tighten the locknut.

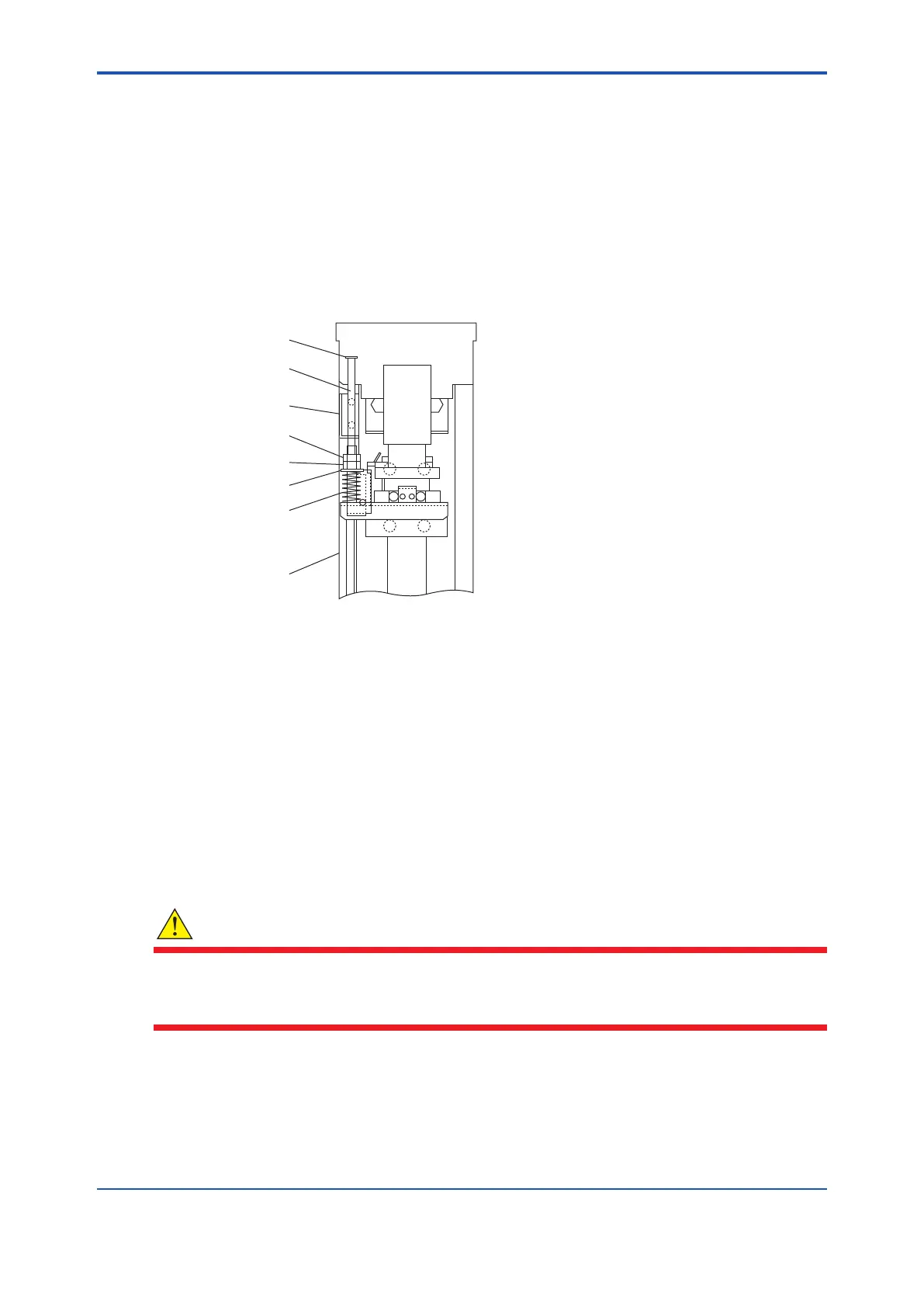

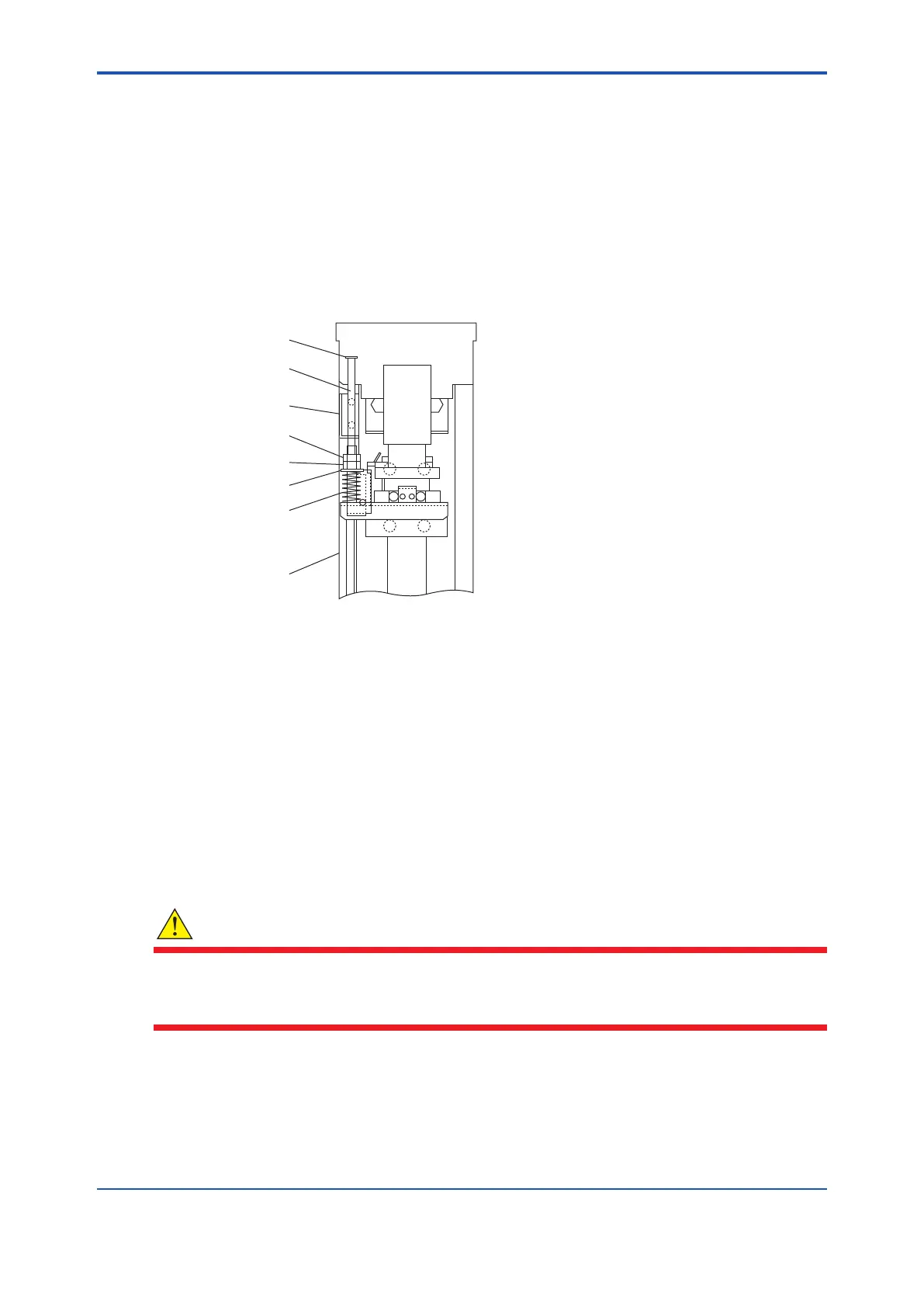

F6.2.ai

Screw

Rod

Guide plate

Locknut

Spring-adjustment nut

Washer

Spring

Chassis

Figure 6.2 Assembly for Adjusting Pressure of Spring in Holder

6.5 Chemical Solution Cannot Be Fed into

Cleaning Chamber

Timer T2 may fail to come into action although the slider on the cylinder has reached the top end

of the cylinder barrel. Consequently, none of the chemical solution is forcibly fed into the cleaning

chamber (i.e., solenoid valve SV1 does not open). One of the reasons is an erroneous DETECT

UPPER LIMIT signal (or the signal is not present).

If this failure occurs, always proceed as follows: First make sure cleaning sequence is nished

and the slider on the cylinder is positioned at the bottom end. Then check the cable wired to the

terminal block for the limit switch.

WARNING

Electrical shock hazards:

Short-circuited cable between terminal 1 and 2 on the terminal box for the limit switch, an

electrical current of 24 VDC, 50 mA maximum passes.

lf any abnormality, such as a broken wire, is found, remedy it. lf you cannot point out any

abnormality in the wiring or localize the cause of failure, contact our sales ofce.

Loading...

Loading...