<4. Operation>

4-9

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

The manufacturer recommends that, in the early stages of operation, you choose from the

following parameters that can be changed and then change them at regular intervals to verify the

cleaning effect so you can nd the optimum conditions for cleaning.

• Concentration of chemical solution (No data is required to change.)

• Interval between WASHs

• WASH time

• Bubbling time

4.4.2 Inspections During Regular Operation

Routine inspection must be made according to the items shown in Table 4.2 to ensure that

the chemical cleaning system is free from faults during regular operation. For inspection and

maintenance implemented during a system shutdown to maintain system performance, see

Chapter 5. For details on the items of inspection for the FLXA202/FLXA21, PH450G pH/ORP

converter or PH8EFP pH sensor, refer to those corresponding manuals.

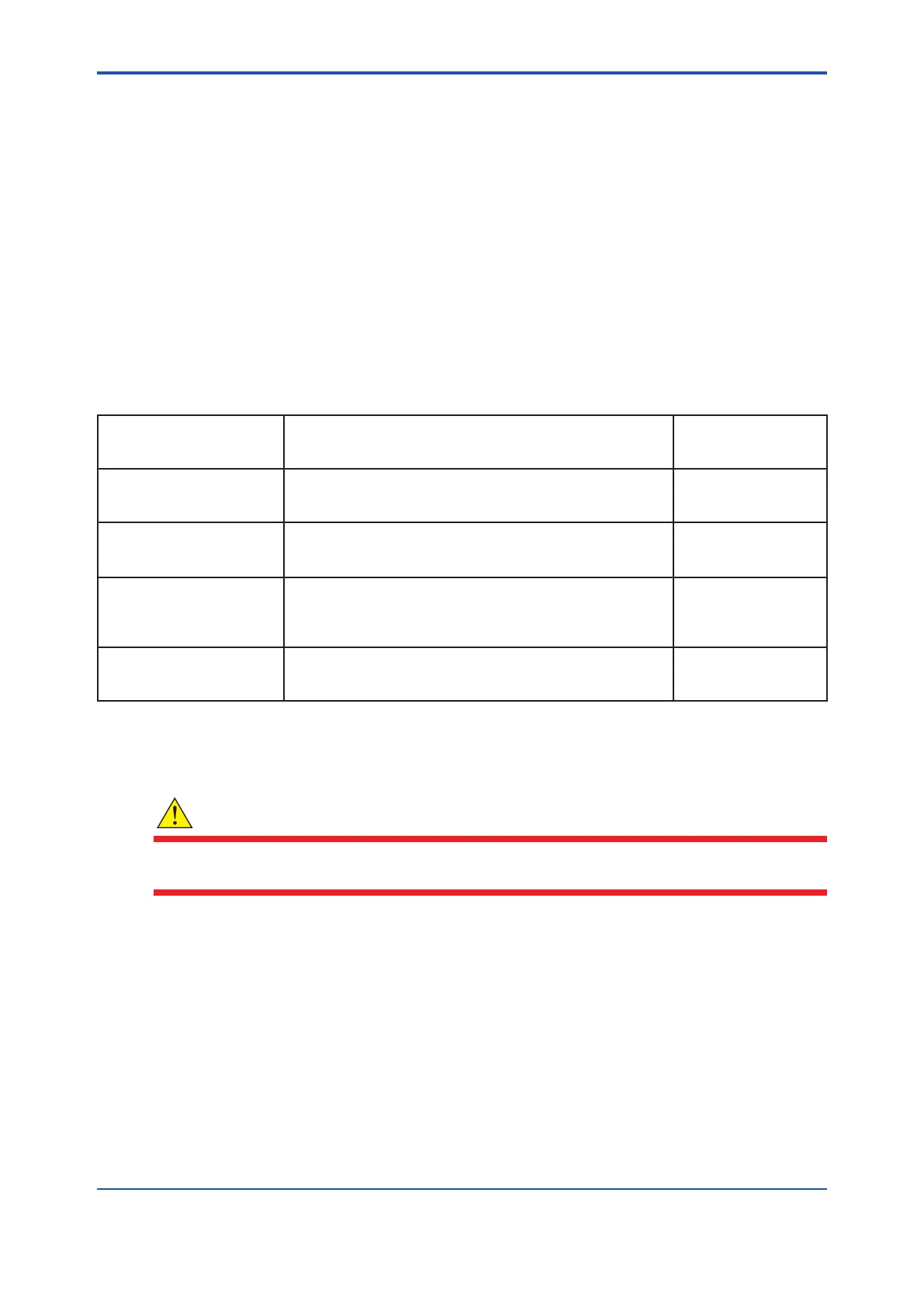

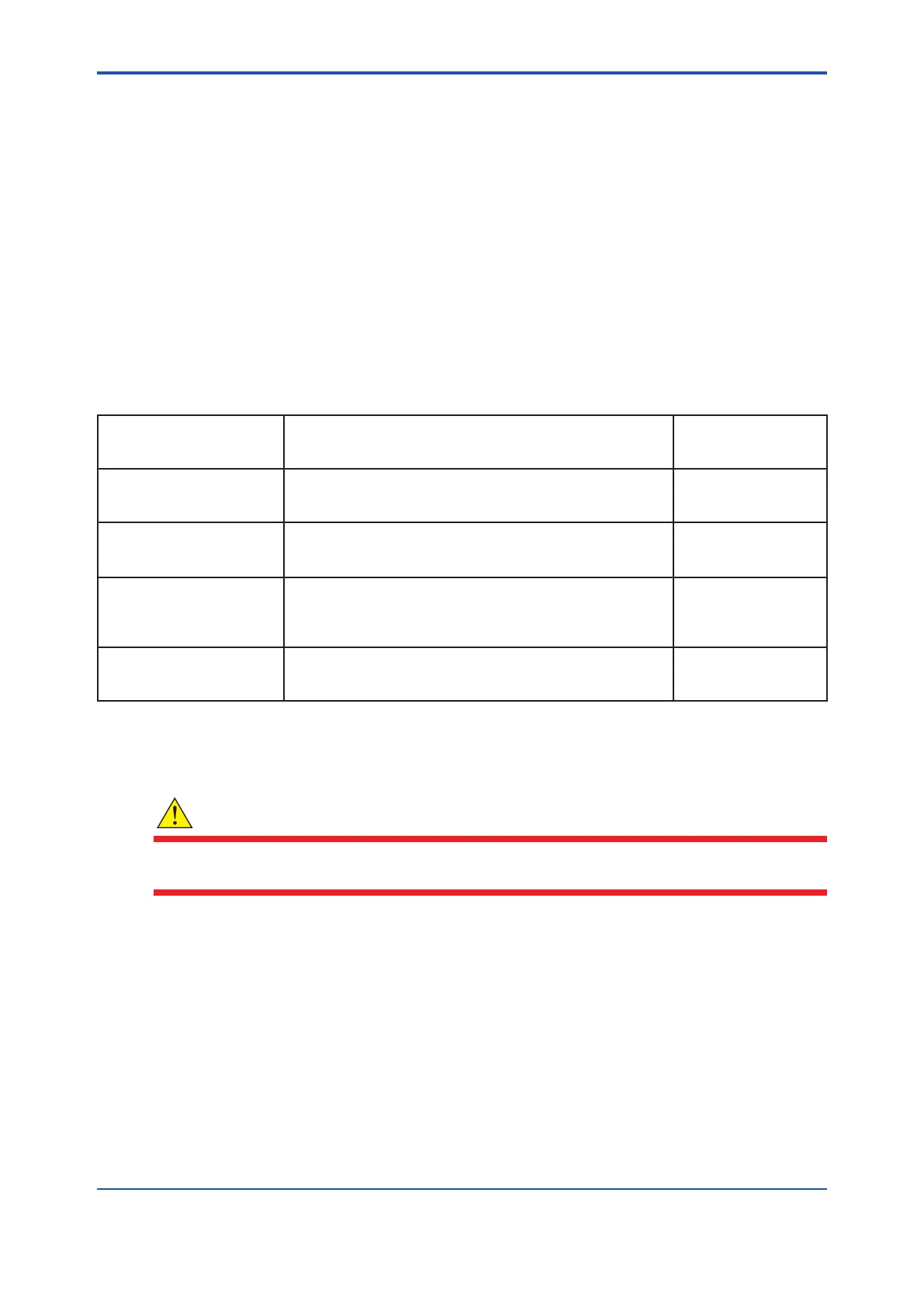

Table 4.2 Inspection During Regular Operation

Inspection Item

Acceptance Criterion

(Corrective Action When Criterion Is Not Met)

Recommended

Frequency of

Inspection

Amount of chemical solution

remaining in holding tank

The tank must holds not less than the required amount (the

level indicated on the tank). (Rell the tank if the liquid is below

the specied level.)

Approximately once a

month

(100 ml per rell)

Amount of contaminants

on the cylinder of PHSHS3

holder

The cylinder must be free of contaminants that would prevent it

sliding properly. In addition, any applied lubricating grease must

provide good 1ttbrication (the cylinder starts moving smoothly).

Approximately once a

month

Pneumatic pressure setting

of pressure reduction valves

in control box

The PG1 and PG2 pressure gauges en the AS1 and AS2

pressure reduction valves must indicate their preset readings,

respectively. (If they fail to indicate the preset readings, adjust

them.)

Approximately once a

month

Amount of contaminants on

the wetted part of sensor

holder

The wetted part must be free of any contaminants that could

get into the cleaning chamber while the sensor holder was

rising or descending.

Approximately once a

month

If your system requires immediate corrective actions as a result of inspection, perform the

necessary maintenance work while observing safety precautions.

WARNING

There is a possibility of personal injury or equipment damage during maintenance of the holder.

Exercise utmost care to ensure that no cleaning takes place during maintenance work.

4.4.3 Behaviour During Power Failure/Restart

The sensor holder moves to its lowest position and stays there, whether the system is in the

measurement mode or the WASH mode, if a power interruption lasts longer than the allowable

time for a momentary power failure in which the system is able to maintain normal operation. The

system resets to the measurement mode when restarted. It goes into the WASH mode, however,

if the MANUAL WASH switch in the control box is left turned on.

4.4.4 Operation When Shutting Down the System

It is fundamental to system operation that the pH sensor be maintained in excellent working

condition and that the system be able to resume normal pH measurement when it is restarted.

Follow the instructions given here before cutting off the power supply.

Loading...

Loading...