<6. Troubleshooting>

6-1

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

6. Troubleshooting

This chapter deals with the corrective actions taken when the system fails to operate normally

due to, for example, a failure in components. For malfunctions regarding the PH450G pH/

ORP Converter or FLXA202/FLXA21 2-Wire Analyzer and PH8EFP pH sensor, refer to the

correspondng user’s manual supplied with these instruments.

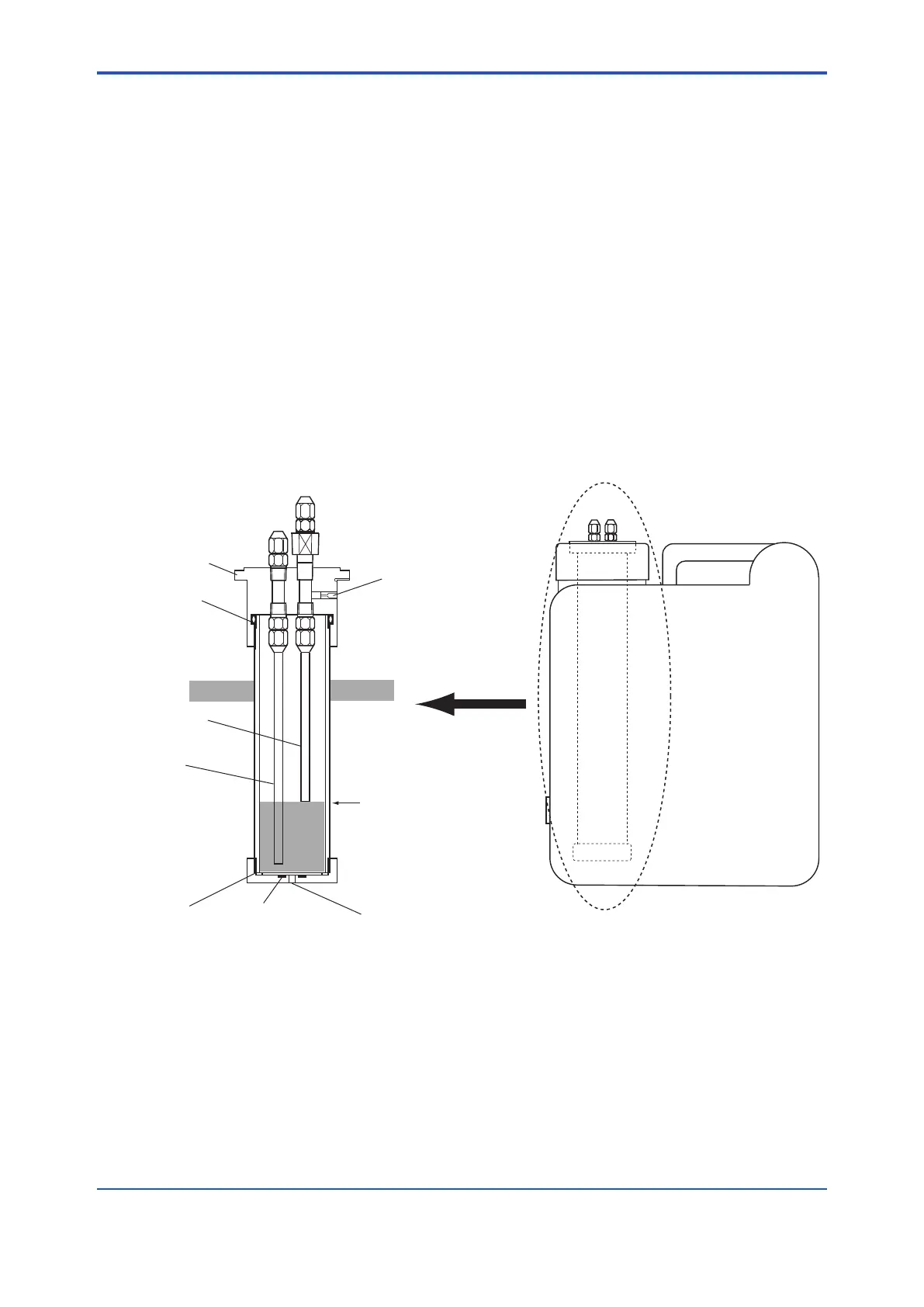

6.1 More Than 100 ml of Chemical Solution at a

Time Is Being Fed to Holder

The primary reason is that air may be leaking from the O-ring in the metering tank. Since an

excessive air leak allows the chemical solution to enter the metering tank up to the level of the

surface of the liquid in the holding tank, more than the required quantity (approximately 100 ml) of

the chemical solution is supplied.

l Corrective action

Tighten the cap fully. If the air leak still persists, check the cylinder barrel for possible cracks and

the O-ring for possible defects. Replace defective components, if necessary.

Cap

O-ring

Pneumatic

pressurizing tube

Tube for

forced feeding

Gasket

Bleed valve

Level of liquid

in holding tank

Level of liquid in metering tank

(capacity: approximately 100 ml)

Fluid inlet

Metering tank

Holding tank for chemical solution

Check

Valve

(Seat)

Figure 6.1 Normal Level of Liquid in Metering Tank

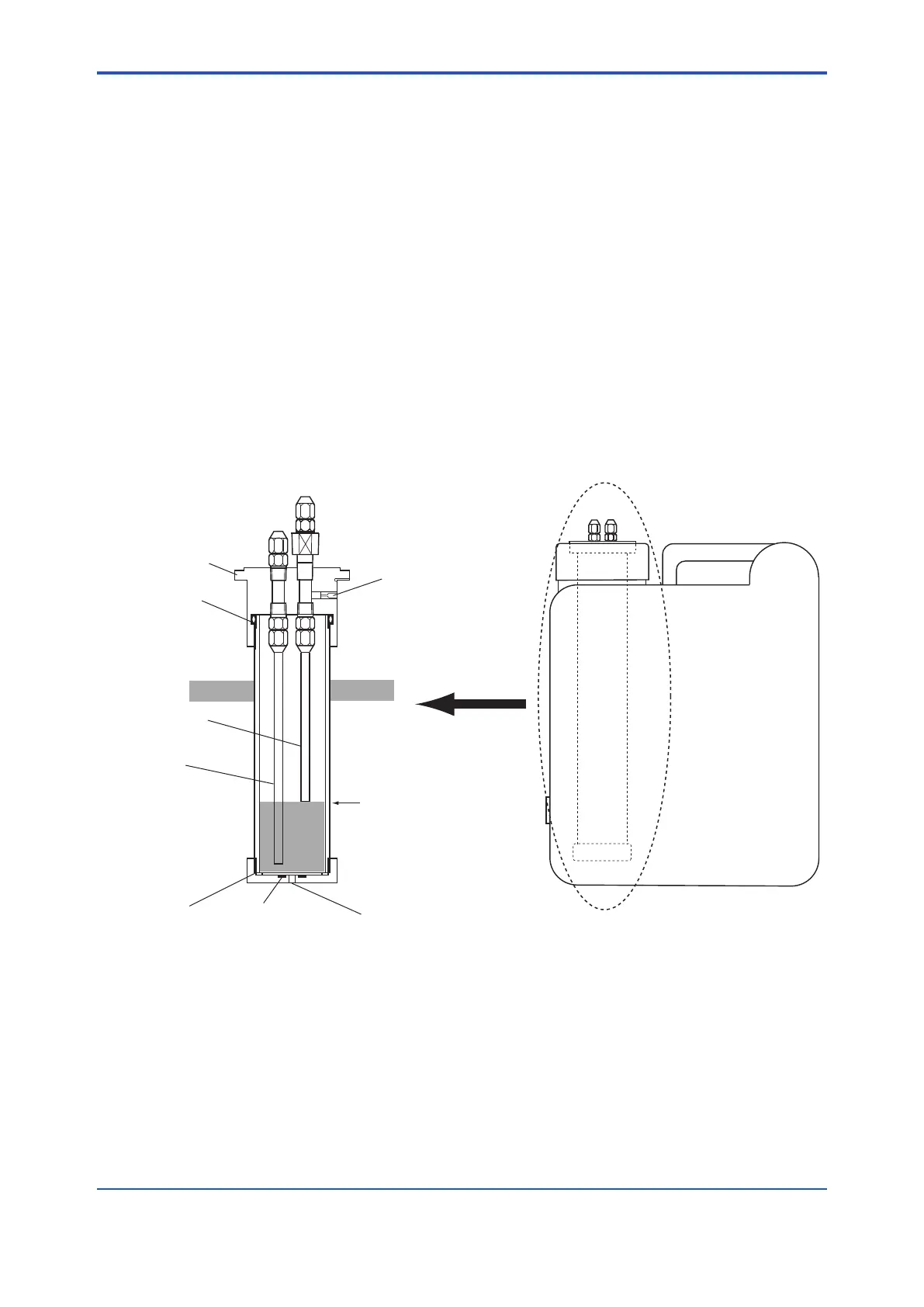

If the holding tank is positioned below the cleaning chamber of the holder conrm that at least a

part of the tubing is positioned above the cleaning chamber. Failure to observe this instruction

may result in the chemical solution fed to the cleaning chamber owing back into the holding tank

after the air bubbling.

Note: If the chemical solution in the cleaning chamber ows back into the holding tank, clean

the bleed valve to prevent it from being clogged.

Loading...

Loading...