<5. Inspection and Maintenance>

5-3

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

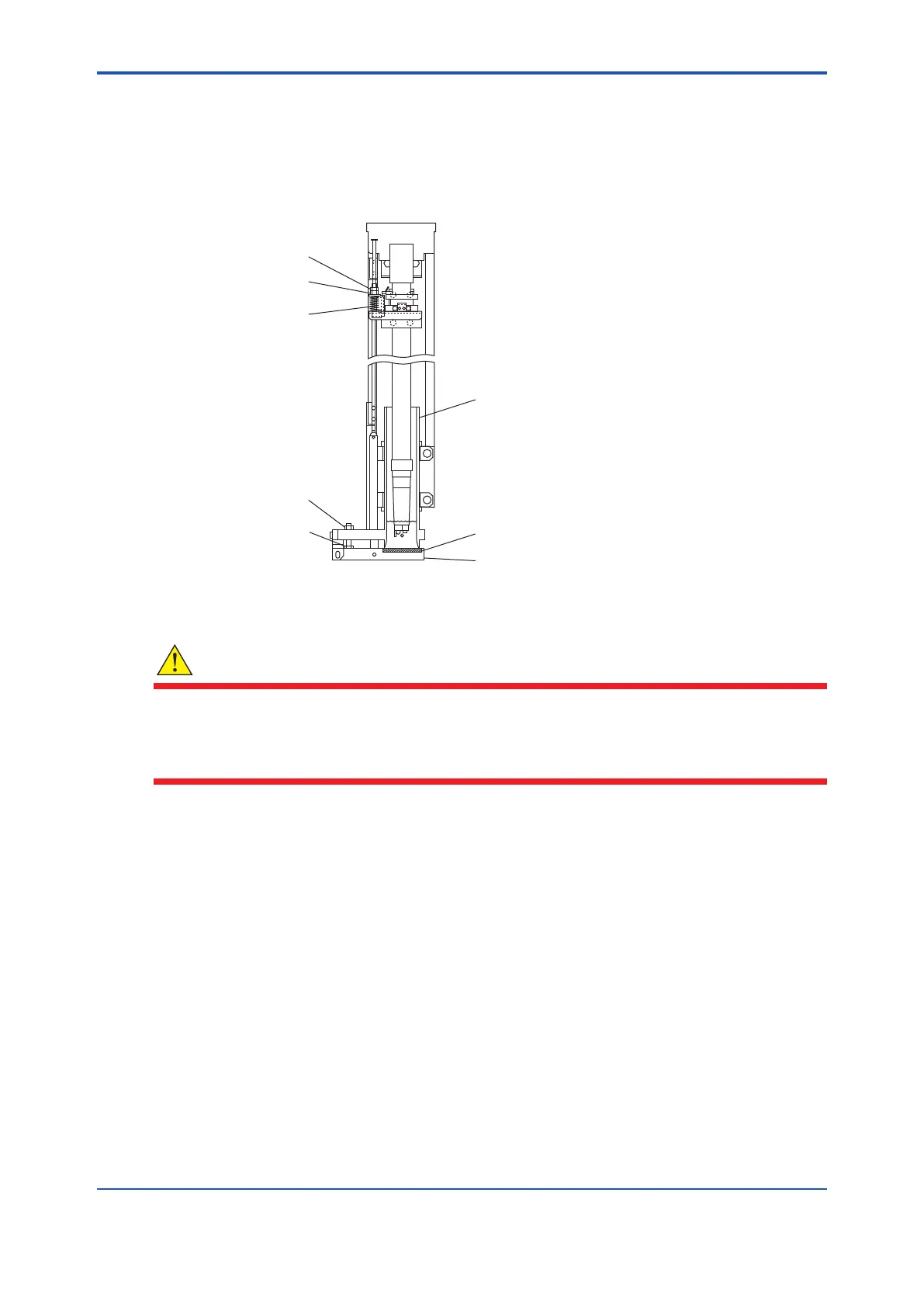

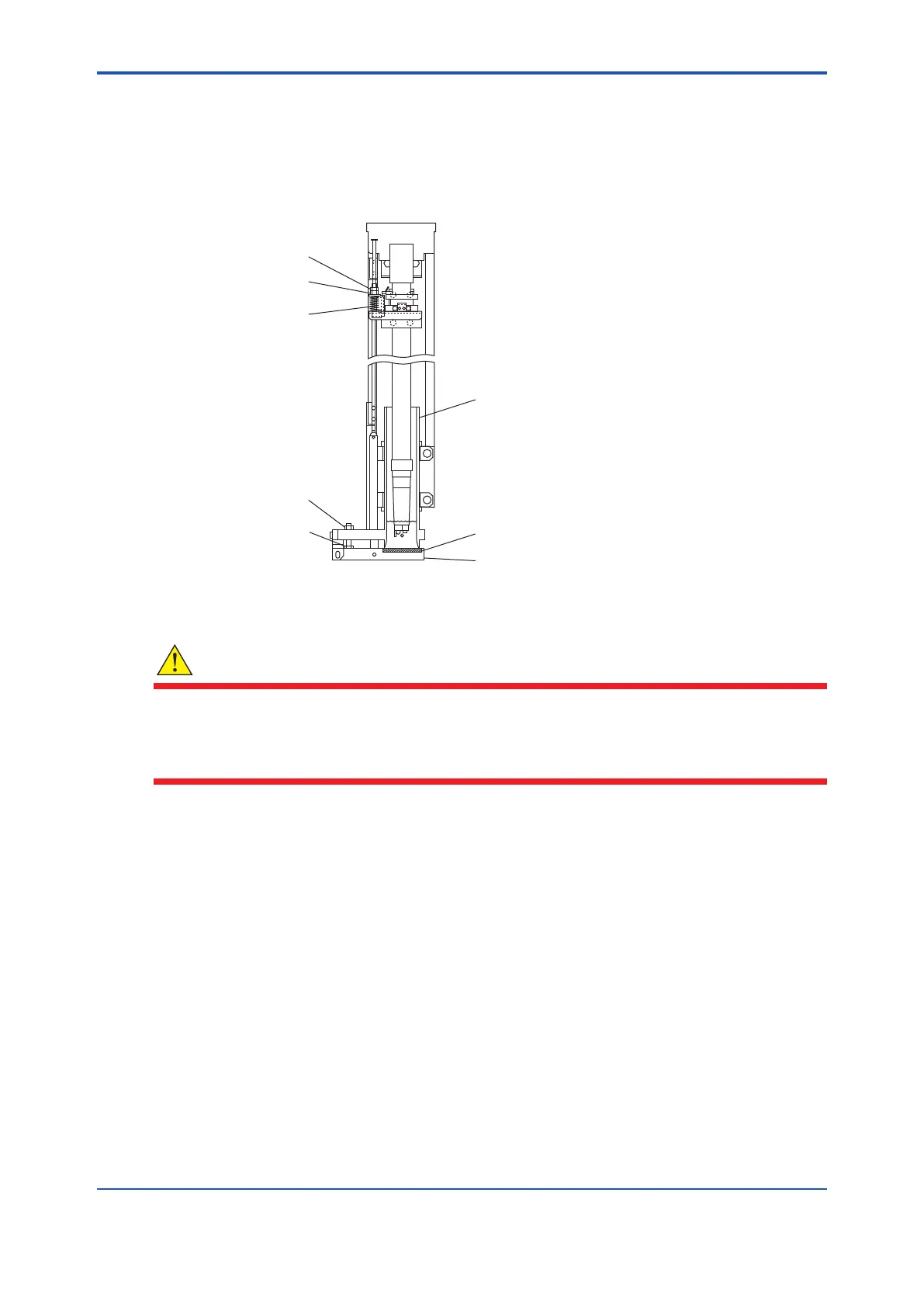

<Standard position of spring-adjustment nut>

The standard position of the spring-adjustment nut is where it is when the spring contracts

9mm from the position of its upper end (free length) which is given when the gasket surface

comes into slight contact with the bottom surface of the cleaning chamber.

c. Tighten the spring locknut.

(3) Tighten the locknut.

F5.1.ai

Spring locknut

Spring-adjustment nut

Spring

Locknut

Stopper

Cleaning chamber

Gasket

Bottom plate

Figure 5.1 Construction of PH8HS3 Holder

WARNING

When highly concentrated sulfuric acid or hydrochloric acid are used, remove those remaining

solutions in the cleaning chamber before starting cleaning.

Sulfuric acid or hydrochloric acid at high-concentration level causes serious damage to human

health and corrosive characteristics to metals. Use proper care to handle these solutions.

5.2.3 Cleaning and Lubricating Pneumatic Cylinder for

Driving the Sensor Holder

The slider on the pneumatic cylinder for driving the sensor holder slides along the cylinder

barrel. Inspect the barrel to make sure that it is free from any foreign matter or dirt. If the barrel

is contaminated with dust which will prevent the slider from moving properly, use a clean cloth to

remove the dust. The slider may stay at its lowest position for a prolonged period depending on

the interval between cleanings. If the slider has been in this position for a long time, it may fail to

start moving smoothly at a preset pneumatic pressure. Wipe off any dust on the cylinder, if any.

If your system has the air cylinder cover, remove the cover to inspect and clean. How to remove

the cover is as follows. When you restore the cover again go backward the procedure.

(1) Keep the sensor holder at the lowest position ( measuring position ).

(2) Remove all 4 screws that x the cover(up and down , 2 screws for each.)

(3) Slide the cover upward to take off.

Loading...

Loading...