<4. Operation>

4-6

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

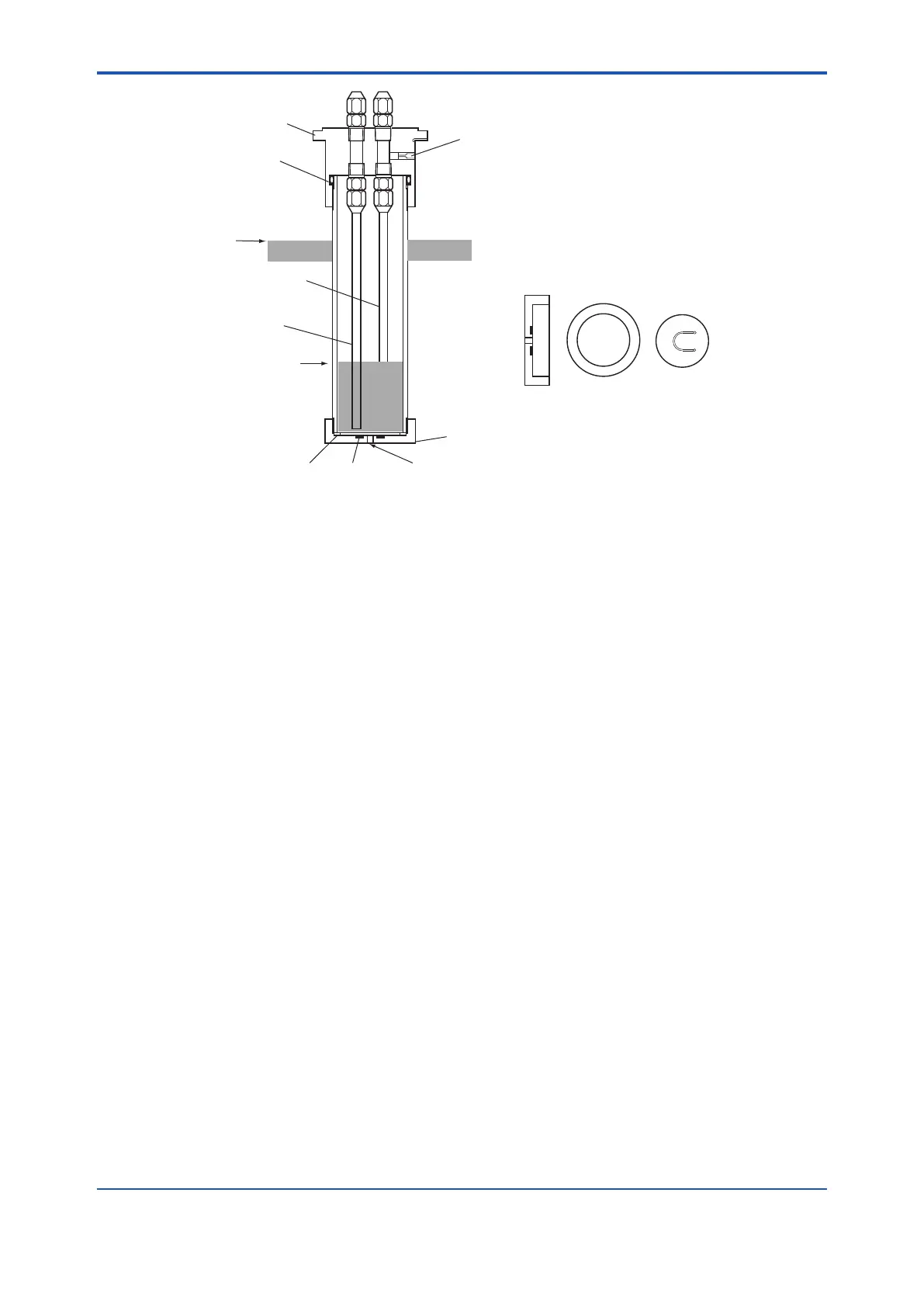

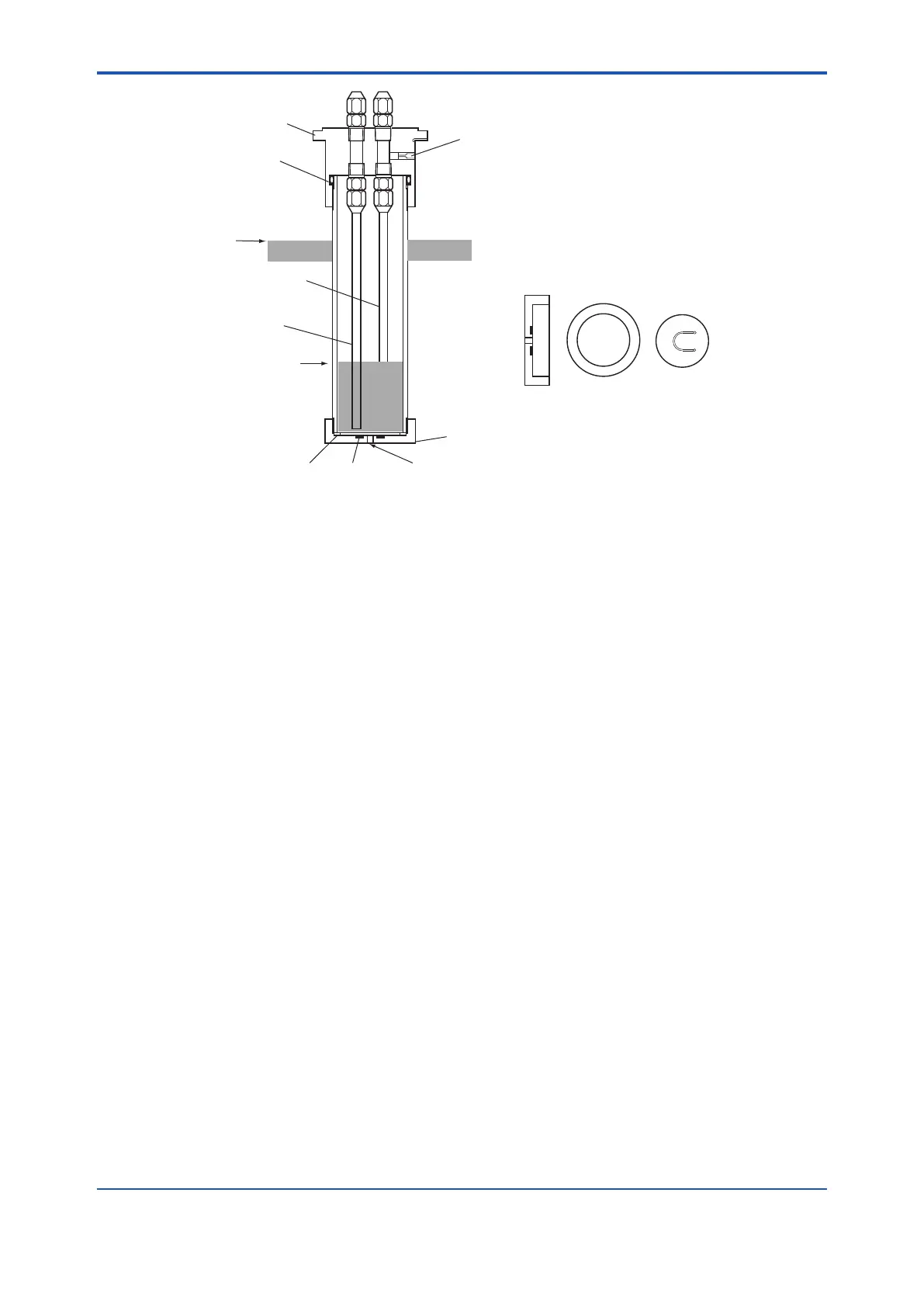

F4.5.ai

Cap

O-ring

Level of chemical

solution in holding tank

Pressurized Tube (F)

Force-feeding Tube (G)

Level of solution

in metering tank

(Volume: approx. 100 ml)

Gasket

Gasket

(Seat)

Chemical Solution Inlet

Check Valve

Bottom

Bottom

Bleed

Check

Valve

(Seat)

Figure 4.5 Metering Tank for constant quantity of chemical solution

4.3.3 Supplying KCl Solution to Reserve Tank

Fill the KCl reserve tank for the pH sensor with a KCl solution. After lling the tank, follow the

necessary procedures, such as removal of air from inside the sensor unit. Refer to user’s

manual, “PH8EFP KCl Filling type pH Sensor” to do the necessary work.

4.3.4 Adjustment of Pneumatic Pressure

(1) Rotate the knobs on the pressure reduction valves (two) in the control box fully counter

clockwise. Pull the red ring around the knob toward you to turn the knob. If the operating unit

is equipped with an AS3 pressure reduction valve, also rotate the knob on this valve fully

counter clockwise.

(2) Supply air (pressure: 300 to 950 kPa {3 to 9.5 kg/cm

2

}) to the control box. Open the stop

valve located in the line for connecting the air source.

(3) Adjust the pressure of the air for forced feeding of the chemical solution (the air is also used

to purge the interior of the control box). Slowly rotate the knob on pressure reduction valve

AS1 clockwise until pressure gauge PG1 in the control box indicates a reading of 20 to 50

kPa {0.2 to 0.5 kg/cm

2

}.

(4) Adjust the pressure of the air for actuating the cylinder. Slowly rotate the knob on pressure

reduction valve AS2 clockwise until pressure gauge PG2 in the control box indicates a

reading of 300 kPa {3 kg/cm

2

}. A pneumatic pressure is then applied to the “Down” port of

the cylinder in the PH8HS3 holder and forces the sensor holder to move down to the lower

end together with the cylinder slider.

(5) Apply a pneumatic pressure of approximately 10 kPa {0.1 kg/cm

2

} to the KCl reserve tank.

If the PH8HS3 holder is equipped with an AS3 pressure reduction valve, use the valve to do

this. Slowly rotate the knob clockwise while observing the reading of the pressure gauge on

the valve.

Loading...

Loading...