<3. Piping and Wiring>

3-1

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

3. Piping and Wiring

3.1 Piping

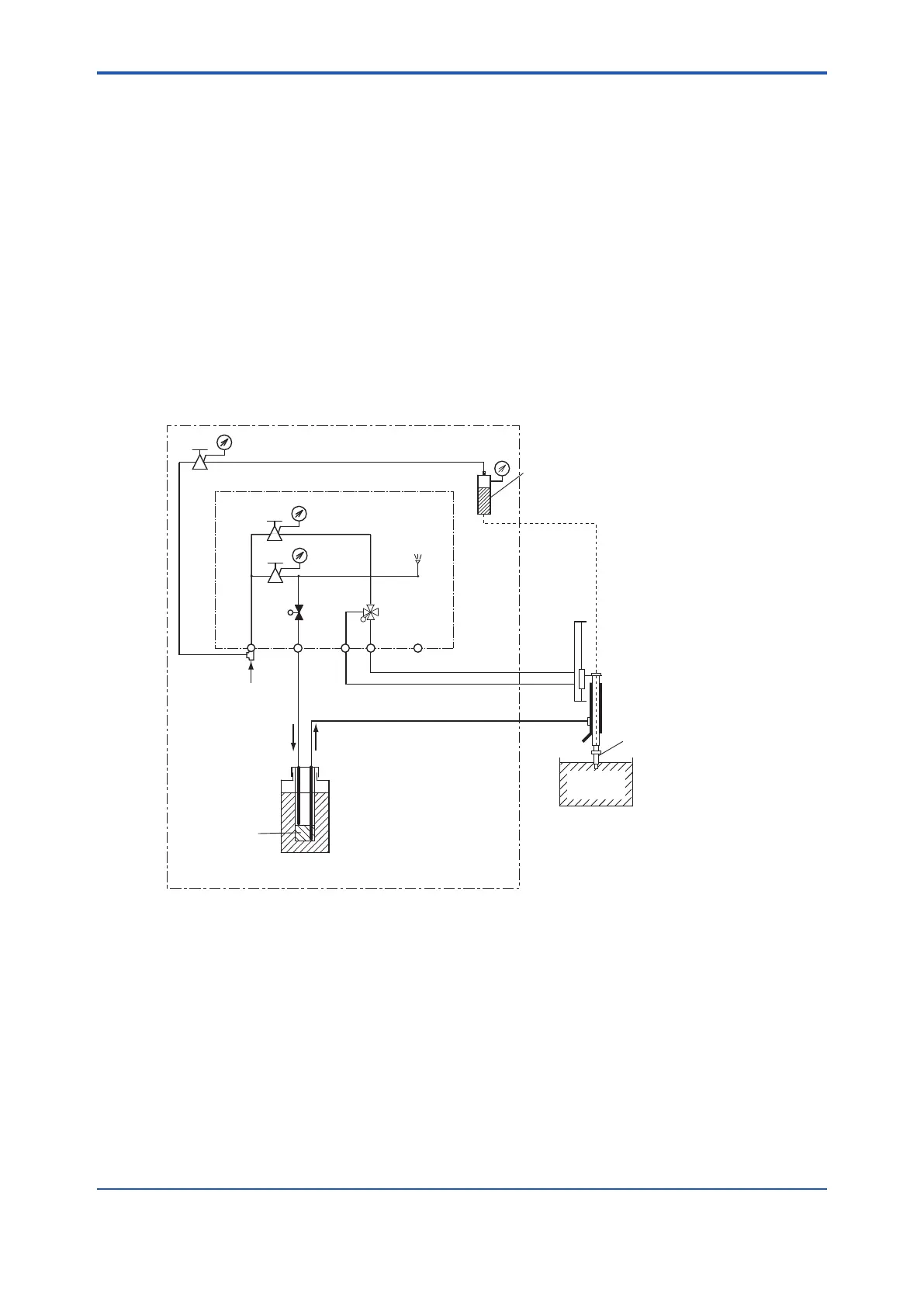

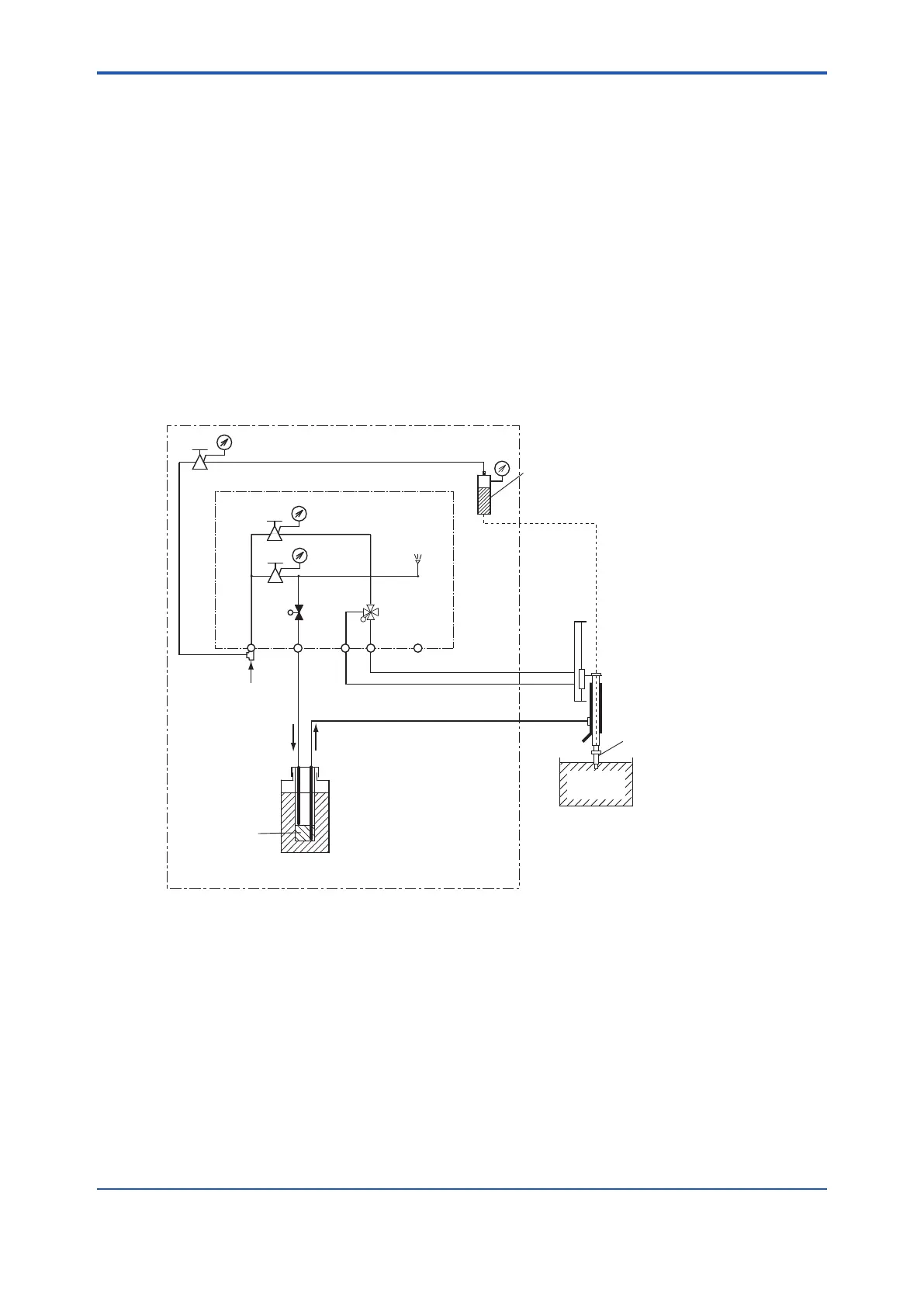

The following lines must be provided to the chemical cleaning pH measuring system.

Lines (2) through (4) are polyethylene resin tubing or joints supplied with the system. Always

make sure that the length of each line is kept to a minimum (less than 10 m).

(1) Line for connecting air source

(2) Line for actuating cylinder to drive sensor pneumatically (upward)

(3) Line for actuating cylinder to drive sensor pneumatically (downward)

(4) Line for forced feeding of chemical solution and air-bubbling

(5) Line for pressurizing KCl reserve tank

Note: If you specify, polyethylene tube or Fluoropolymer (PTFE) tube of 40 m in length come with PH8SM3

with their corresponding tting.

If you do not use the piping materials that came with your system, refer to the notes given in

Subsection 5.1.1. Figure 3.1 shows the pipe lines in the system.

AS1:

AS2:

AS3:

A

F G

B C D E

K

J

H

SV1

SV2

PH8SM3 Operating unit for chemical cleaning system

AS3

AS1

AS2

PG3

PG1

PG2

Pressure reduction valve

for forced feeding of

chemical solution

Pressure reduction valve

foe actuating cylinder

Pressure reduction valve

(optional) for pressurizing

the KCl tank

pH sensor

KCl tank (medium pressure)

(The KCl tank of the pH

sensor is used)

Control box

Dedicated tube

PH8HS3

Holder

Process

liquid bath

Chemical solution

Tank (20 l)

Internal tank

Air

SV2:

SV1:

PG1:

PG2:

PG3:

Pressure gauge

Pressure gauge

Pressure gauge (optional)

2-way solenoid valve

(N, C)

4-way solenoid valve

Purge

A:

B - F:

G - H:

C - J:

D - K:

Rc1/4 or 1/4NPT

Pneumatic line raise

the sensor holder

Pneumatic line to lower

the sensor holder

Pneumatic line

for forced feeding of

chemical solution

<Piping>

Air source connection

Line for forced feeding

of chemical solution

(purge air outlet)

Figure 3.1 Piping Diagram

Loading...

Loading...