8.6.5 Setting Rolling direct.

Attention!

It is essential to check the direction of rotation of the fan during the initial commissioning. To do this,

note the direction of the arrow on the fan housing. We will not be responsible under any circumstances

for warrantee for damage caused because the direction of rotation is wrong!

When connected in accordance with the connection diagram, the standard rotary direction “RIGHT” =

|

CW

|

results under factory settings. A change of direction is feasible by exchanging the phase

sequence in the motor connection or through reprogramming.

Rotat. Direction

By selection of the parameter “Direction of rotation” and

following pressing the P key, the direction of rotation can

changed to

|

CCW

|

for anti-“clockwise” =

|

CCW

|

direction of

rotation.

Pressing the P key causes the value that has been set to be

accepted.

Rotat. Direction

If the rotary direction is reversed with an available modulation, it is initially reduced to “0” (discon-

nected) and subsequently increased back to the default value.

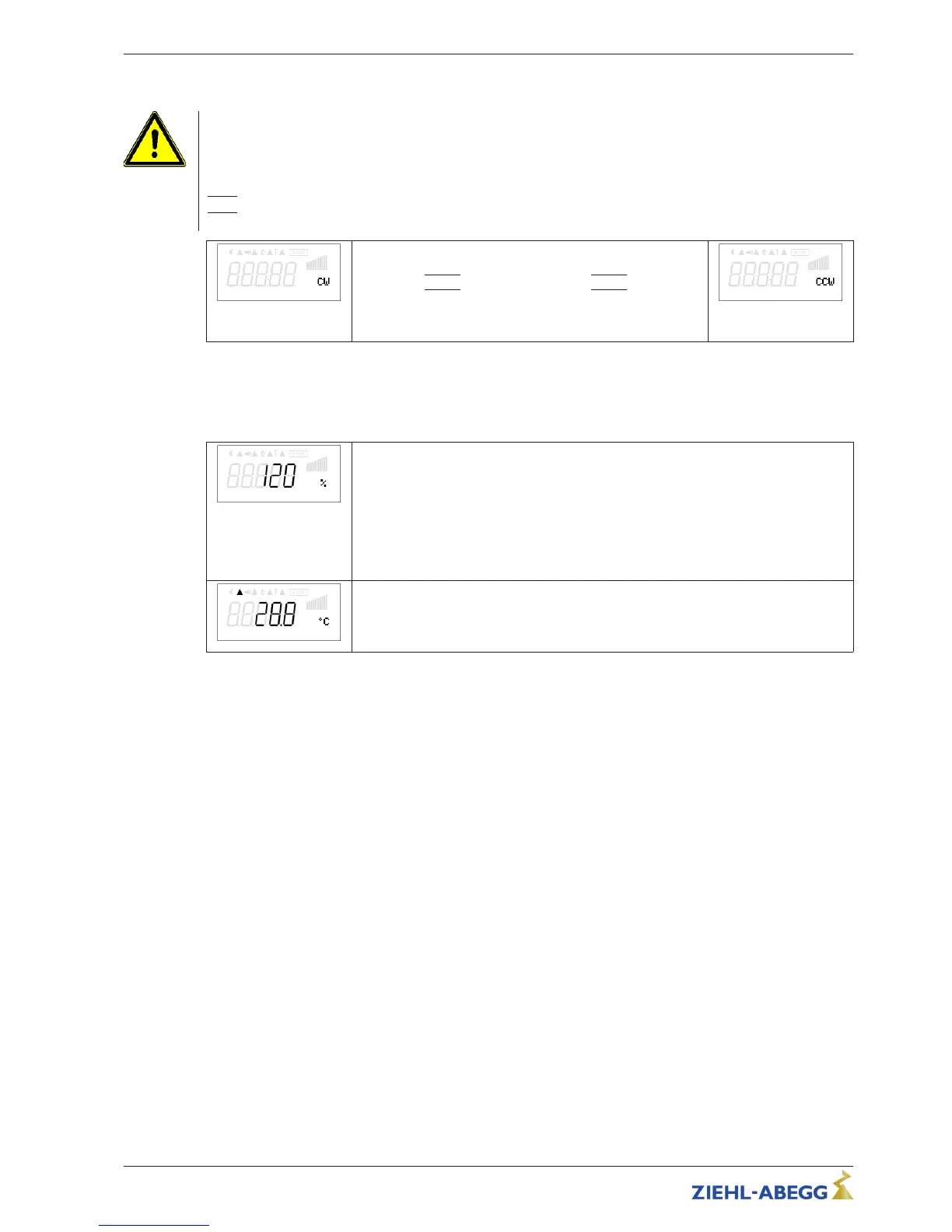

8.6.6 Setting Current limit

Current limit

As an additional safety function the device has a current limit, this can be adapted if

necessary.

The setting refers to the motor rated current of the device (100 % = setting: MotorRa-

tedCurr.).

On exceeding the percentage value set here, the modulation is reduced until the set

current is set again. This prevents overloading of the motor.

Setting range: 100...130 %

Factory setting: 120 %

E1 Actual

Active current limit is signaled by a bright triangle in the display

Operating Instructions Fcontrol Basic – model series FSDM2.5..50AM Programming

L-BAL-E174-GB 1704 Index 005 Part.-No.

33/49

Loading...

Loading...