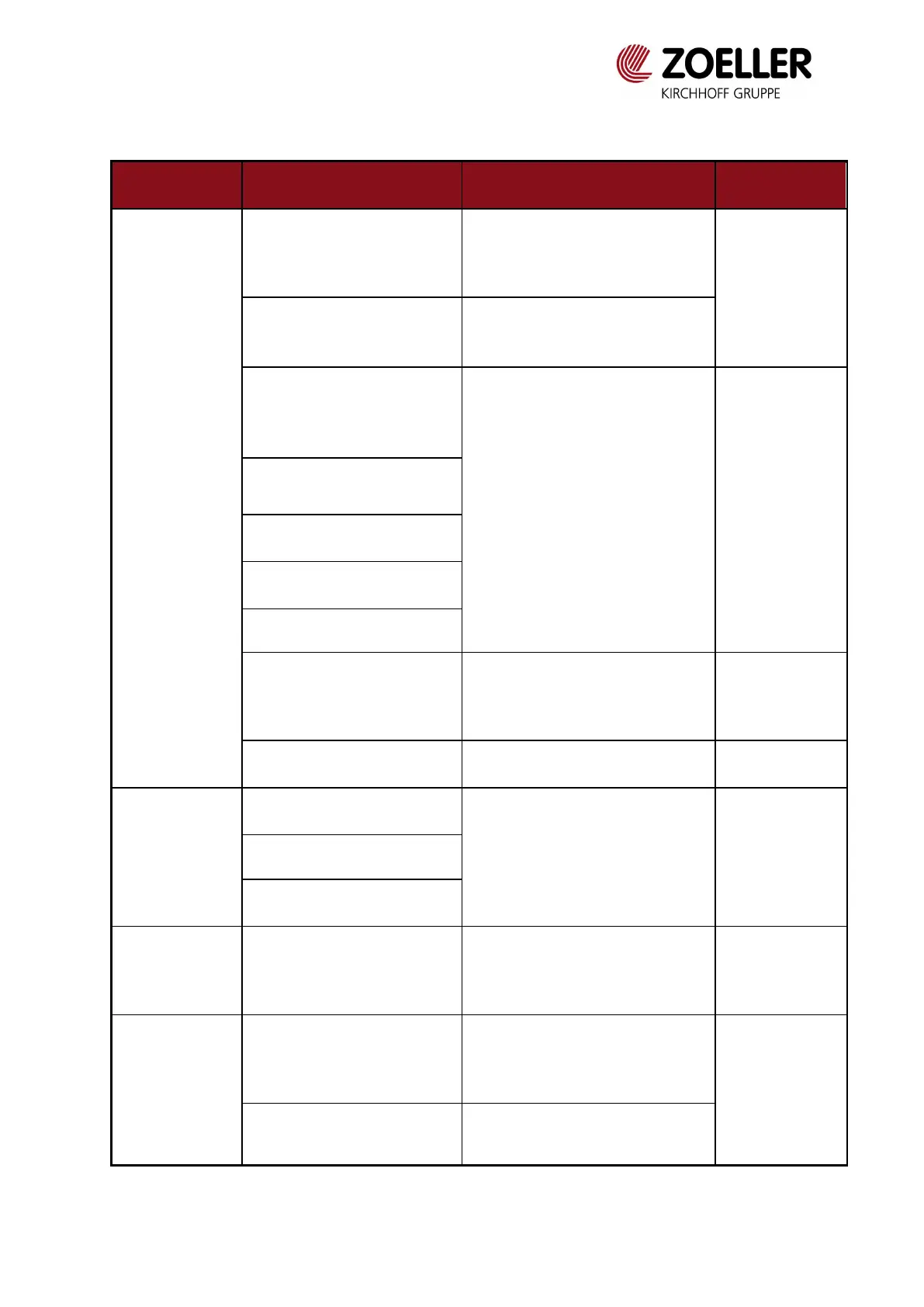

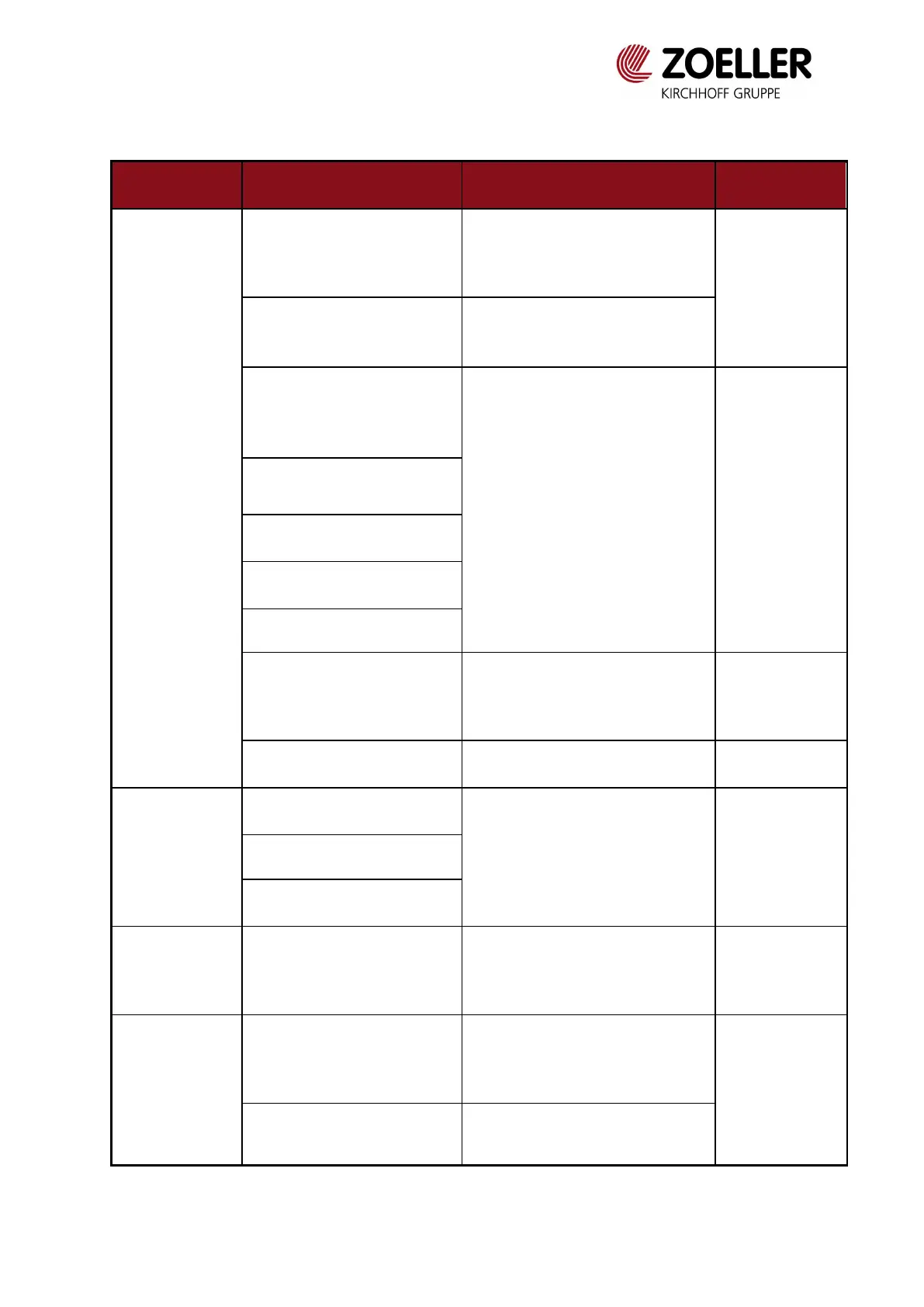

Possible faults 57

10.2 TROUBLESHOOTING

Decrease in

power or

operating speed

Check engine speed

(→ chassis manual)

One loading cycle should last

approx. 22 s.

Too low oil level in the

hydraulic oil tank

Top up oil to the recommended

level.

Too much foam forms in the

oil tank; the pump partly

receives oil foam

Use recommended oil type.

Change oil.

Replace seals, check connections,

tighten if necessary

(→Hydraulic oil change)

The oil heats up too much

due to too high viscosity

Water condensate in the oil

tank

Leaking hoses, pipes or

connectors

Pressure relief valves for main

pressure, back pressure or

holding pressure are

incorrectly set, dirty or stuck.

Return to ZOELLER service for

cleaning, adjustment or

replacement.

Replace ventilation filter in the

tank

Oil pressure too

low, even though

the hydraulic oil

pump is working

correctly

Incorrectly set pressure relief

valve

Return to ZOELLER service for

cleaning, adjustment or

replacement.

The pressure relief valve jams

A leaky connection or blocked

nozzle hole in the block

The hydraulic oil pump is

damaged if the pressure

drops for a long time when

the oil is warm

Replace the hydraulic oil pump

Manual control:

Pressing the

button does not

start the function

There is no controlling

voltage or voltage is too low

(<20V) or the button is

damaged

Check the electrical installation

Solenoid valves are damaged,

or the valve slider is jamming

Check solenoid valves

Return to ZOELLER service for

Loading...

Loading...