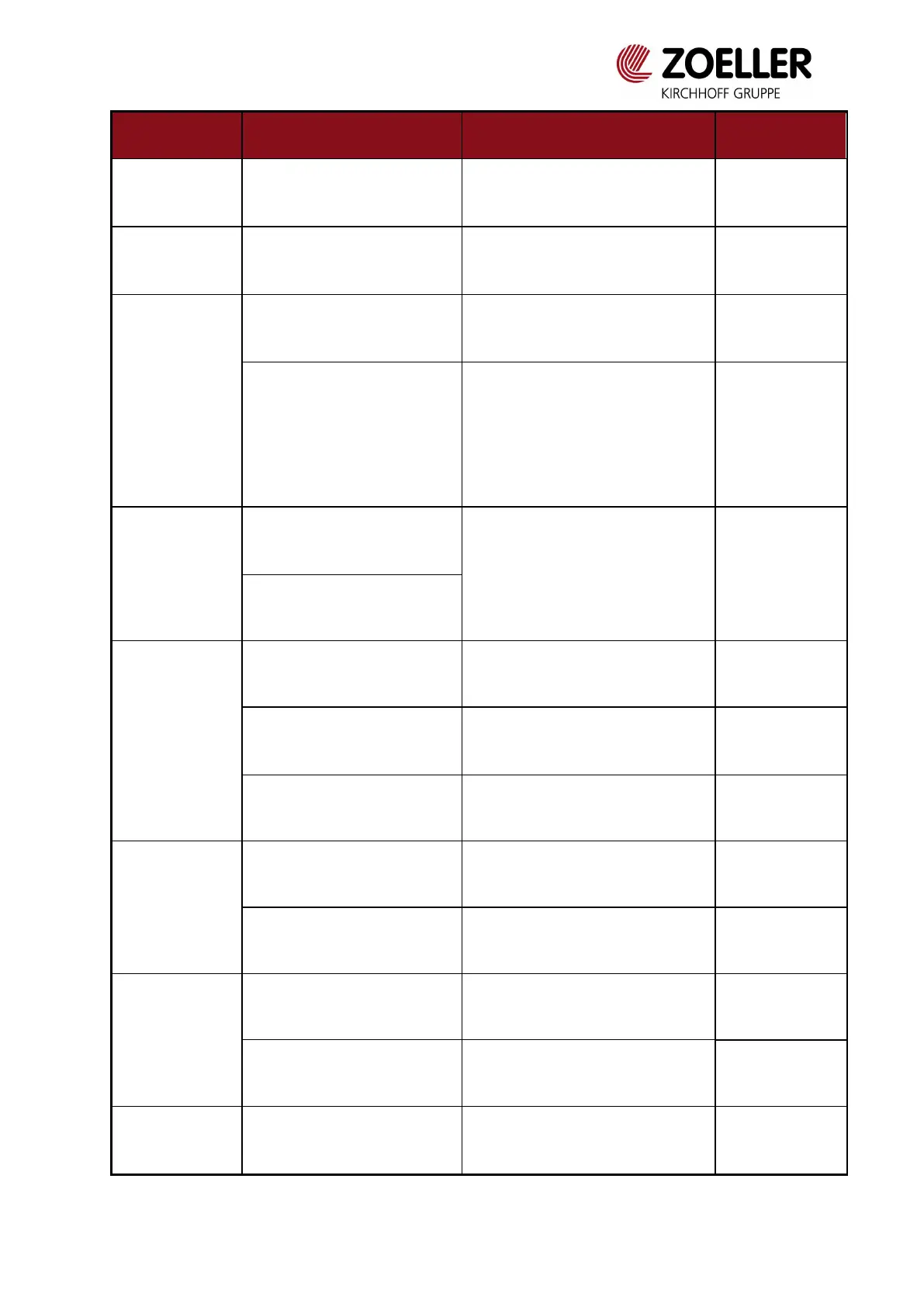

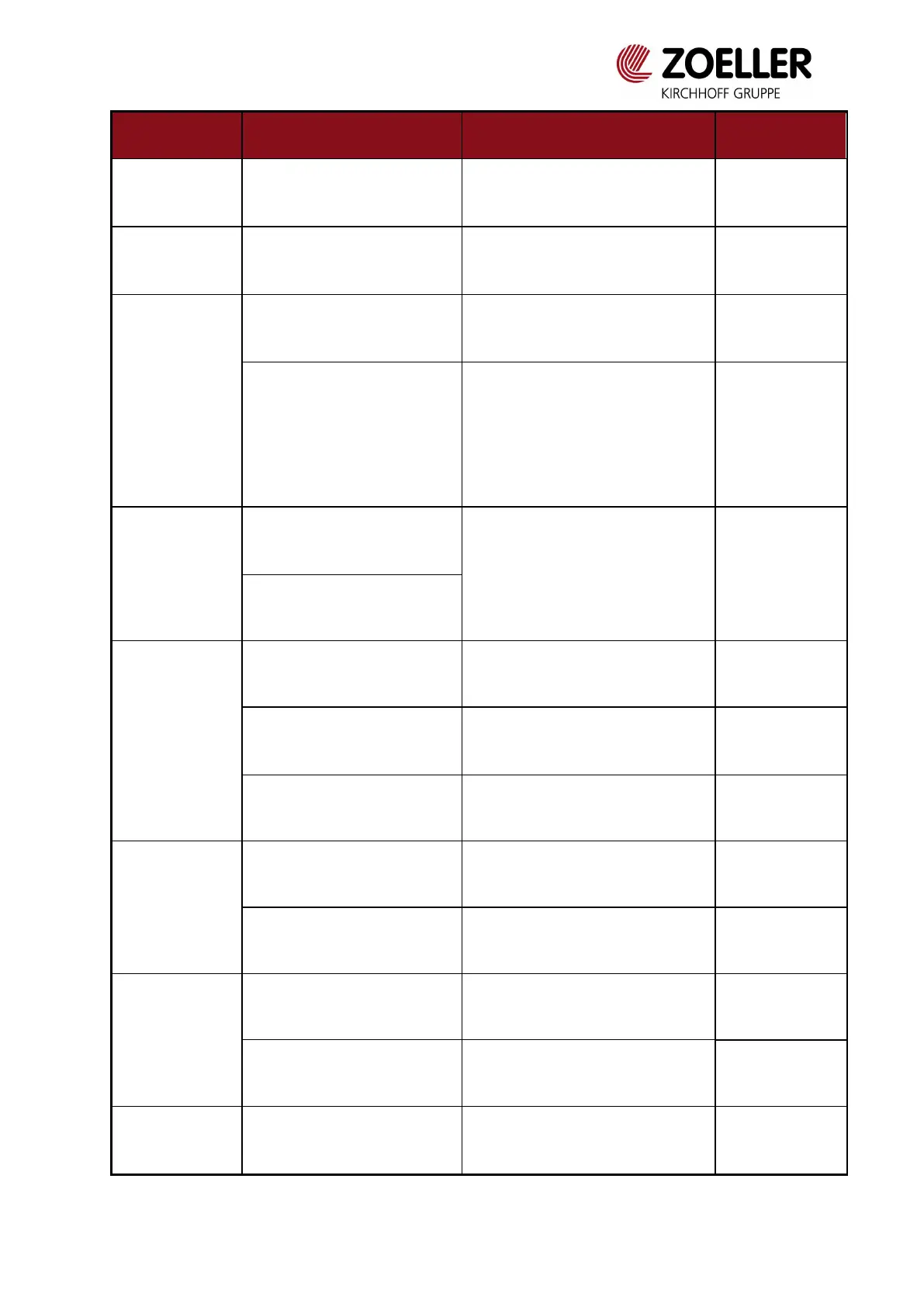

No circulation pressure or

control pressure due to

contamination or jamming

cleaning, adjustment or

replacement.

Sudden

movements or

vibrations

Pressure relief valves are dirty

or stuck.

Return to ZOELLER service for

cleaning, adjustment or

replacement.

In the case of

automatic or

semi-automatic

mode, the

compaction

mechanism

stops at one of

the 4 end

positions

Clean the limit switches and

check for a short to ground

Wyczyścić wyłączniki krańcowe i

sprawdzić pod kątem zwarcia z

masą

Electronic control system is

defective

Check the LEDs in the control box.

Replace the electronic control

system

In the case of

automatic or

semi-automatic

operation, the

"Lift slider" cycle

starts too soon.

The impulse from the

pressure switch arrives too

early

Return to ZOELLER service for

cleaning, adjustment or

replacement.

Pressure switch defective

The compaction

mechanism does

not start after

pressing the

START button,

the speed

increase does

not work

Emergency STOP has been

activated

Unlock the emergency STOP

Supply voltage too low (U

<20 V)

Check the electrical installation

and inform the service department

if necessary

Damaged or wet START

button

Check the button and replace if

necessary

Hydraulic oil

appears on the

hoses.

Tighten screw connections

Hydraulic oil

leaks from the

valves

Replace seals and possibly the

valve

Hydraulic oil

leaks from the

cylinder

Loading...

Loading...