Single and dual input analyzers for pH/Redox (ORP)

AX416, AX436, AX460, AX466 & AX468 8 Simple Fault Finding

62 IM/AX4PH Rev. P

8 Simple Fault Finding

8.1 Error Messages

If erroneous or unexpected results are obtained, the fault may

be indicated in the Operating Page by an error message – see

Table 8.1. However, some faults may cause problems with

analyzer calibration or give discrepancies when compared with

independent laboratory measurements.

8.2 Calibration Fail Message or No Response to

pH/Redox Changes

The majority of problems are associated with the electrodes and

cabling. Replace the electrodes as an initial check – refer to the

appropriate instruction manual. It is also important that all

program parameters have been entered correctly and have not

been altered inadvertently – see Section 7, page 56.

If the above checks do not resolve the fault:

1. Check that the analyzer responds to a millivolt input.

Connect a pH simulator, such as Model 2410, to the

transmitter input; +ve to glass and –ve to reference – see

Section 6.4, page 50 or 6.5. Select the

CONFIG. SENSORS

page and set the Probe Type to Redox or ORP. Check that

the analyzer displays the correct values as set on the

simulator.

Failure to respond to the input indicates a fault with the

analyzer which must be returned to the Company for

repair. Correct response, but with incorrect readings,

usually indicates a calibration problem. Recalibrate the

analyzer as detailed in Section 7.

2. Use the pH simulator to carry out an impedance check on

the analyzer, i.e. glass to reference, glass to earth and

reference to earth – refer to simulator manual.

If the analyzer fails this test, check for moisture within the

transmitter and in particular the terminal compartment. It is

vital that all evidence of moisture is removed with the use

of a hot air drier.

3. Reconnect the electrode cable and connect the simulator

to the electrode end of the cable. Repeat the procedures

1) and 2) above. If the analyzer fails test 2), check for

moisture around the connections and check that the

insulation on the inner co-axial conductor is clean and that

the graphite layer has been removed.

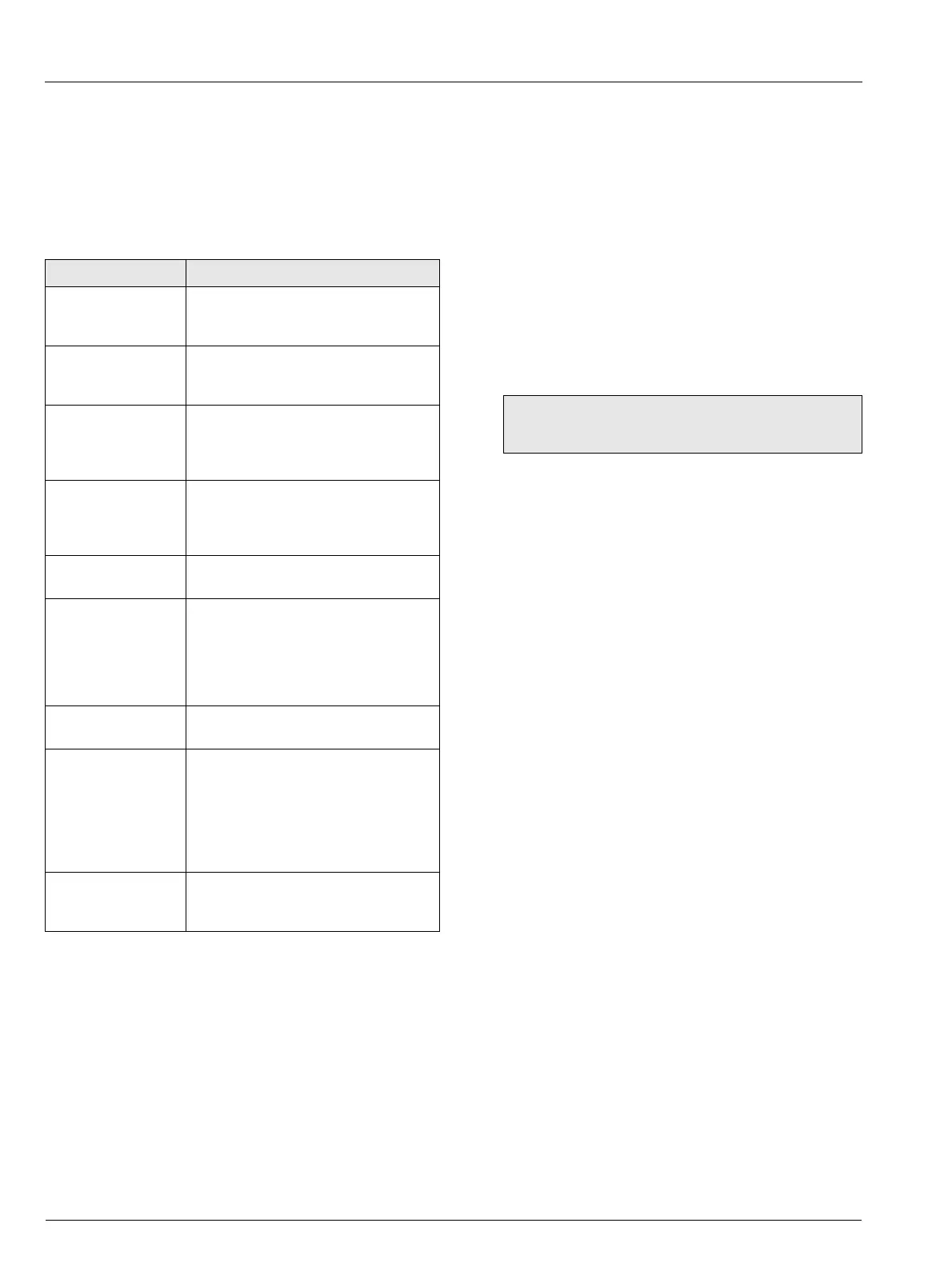

Error Message Possible Cause

A: FAULTY Pt100

A: FAULTY Pt1000

A: FAULTY BALCO

Temperature compensator/associated

connections for Sensor A are either open

circuit or short circuit.

B: FAULTY Pt100

B: FAULTY Pt1000

B: FAULTY BALCO

Temperature compensator/associated

connections for Sensor B are either open

circuit or short circuit.

A: CAL LOW SLOPE

B: CAL LOW SLOPE

Although the calibration has not failed, the

electrode pair associated with the sensor

indicated is becoming fatigued and

replacement is recommended.

A: PH CAL FAILED

B: PH CAL FAILED

The calibration of the sensor indicated has

failed. Check buffer values and repeat

buffering. If the fault persists, replace the

electrodes.

WASH INHIBITED

Wash Function is set to Off. Set Wash

Function

to On – see Section 2.3.3, page 8.

A: OUT OF SAMPLE

A: BROKEN CABLE

(alternating display)

B: OUT OF SAMPLE

B: BROKEN CABLE

(alternating display)

1. The sensor indicated is not fully immersed

in sample.

2.The cable associated with the sensor

indicated may be damaged.

A: BROKEN CABLE

B: BROKEN CABLE

The cable associated with the sensor

indicated may be damaged.

A: LOW GLASS IMP.

A: BROKEN CABLE

(alternating display)

B: LOW GLASS IMP.

B: BROKEN CABLE

(alternating display)

1. The glass electrode associated with the

sensor indicated may be broken.

2.The cable associated with the sensor

indicated may be damaged.

3.The connections associated with the

sensor indicated may be faulty.

A: CHECK REF.

B: CHECK REF.

The reference electrode associated with the

sensor indicated may need cleaning or the

sensor may need replacing.

Table 8.1 Error Messages

Note. A normal laboratory mV source is not suitable

for use as a pH simulator.

Loading...

Loading...