7

Basic Selection

3ADW000197R0101 DCS800-R Sel e a

Basic Selection

Technical preconditions and limits

If an electrical drive is in operation for several years, most often discussions will be

started about items like:

- better factory automation based on latest technology

- decrease of standstill time of production

- availability of spare parts

- increase of productivity; perhaps an enlargement of the whole installation using

both types of drives, DC and AC drives

- and other arguments

These wishes can be turned into real life by:

- upgrading the drive itself completely

- upgrading only the converter, which had controlled the DC motor

- upgrading the converter´s electronics only

- upgrading a part of the converter´s electronics.

For a final solution, all the benefits described by:

• higher production • more accurate control

• design of state of the art • others

will be compared with the disadvantages of revamping described by:

• standstill time of production • hardware cost • training etc.

If this comparison is based on an upgrade of the converter´s electronics the Re-

build kit, which is described within this document, may be a solution. Before the fi-

nal decision is made to use a Rebuild kit, the configuration of the existing drive

needs to be checked more in detail to make sure the kit fulfills all demands.

Selecting the suitable Rebuild kit

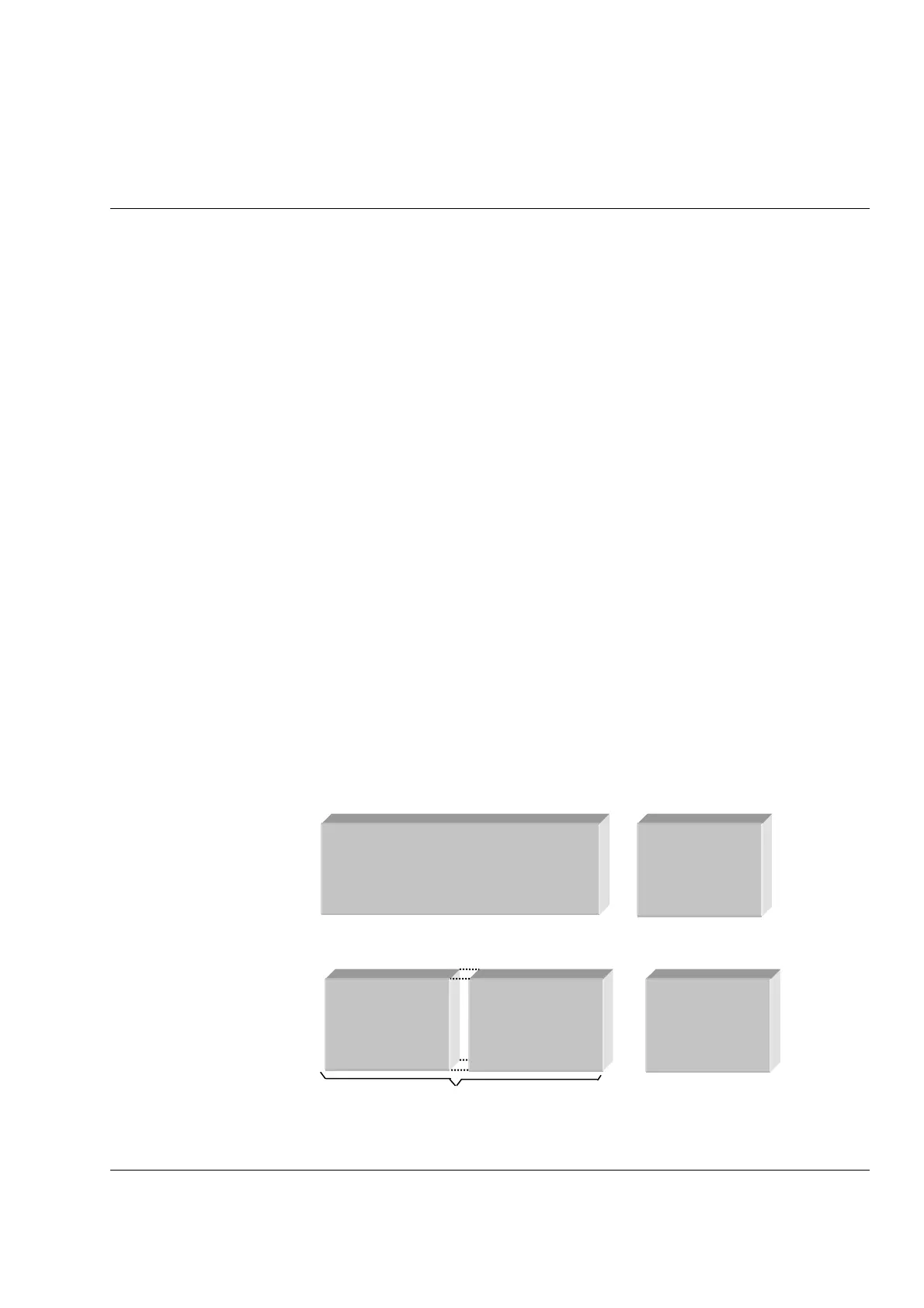

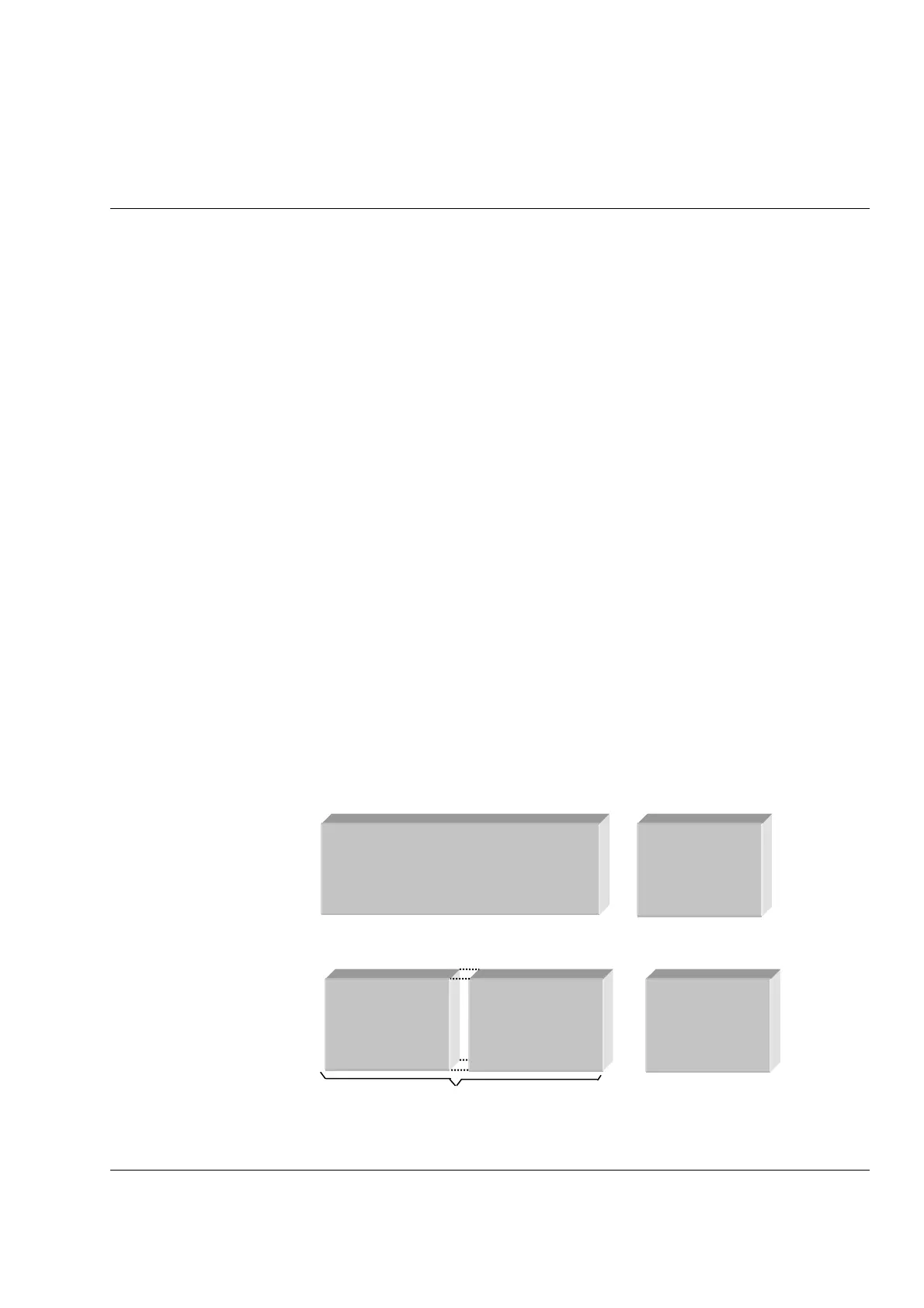

The basic structure of a converter to control a DC motor looks like this:

The electronics of the existing converter indicated by the left box above is splitted

into 2 boxes in the kit.

The Rebuild kit can be used for armature bridges in non-regenerative or regenera-

Rebuild kit

electronics:

interface to

PLC

electronics:

interface to

thyristor

bridge

thyristor

bridge

Existing

Converter control electronics

with interface to:

- thyristor bridge

- PLC

thyristor

bridge

Loading...

Loading...