Electrical installation: AC input, motor and brake 53

Motor power cable shielding

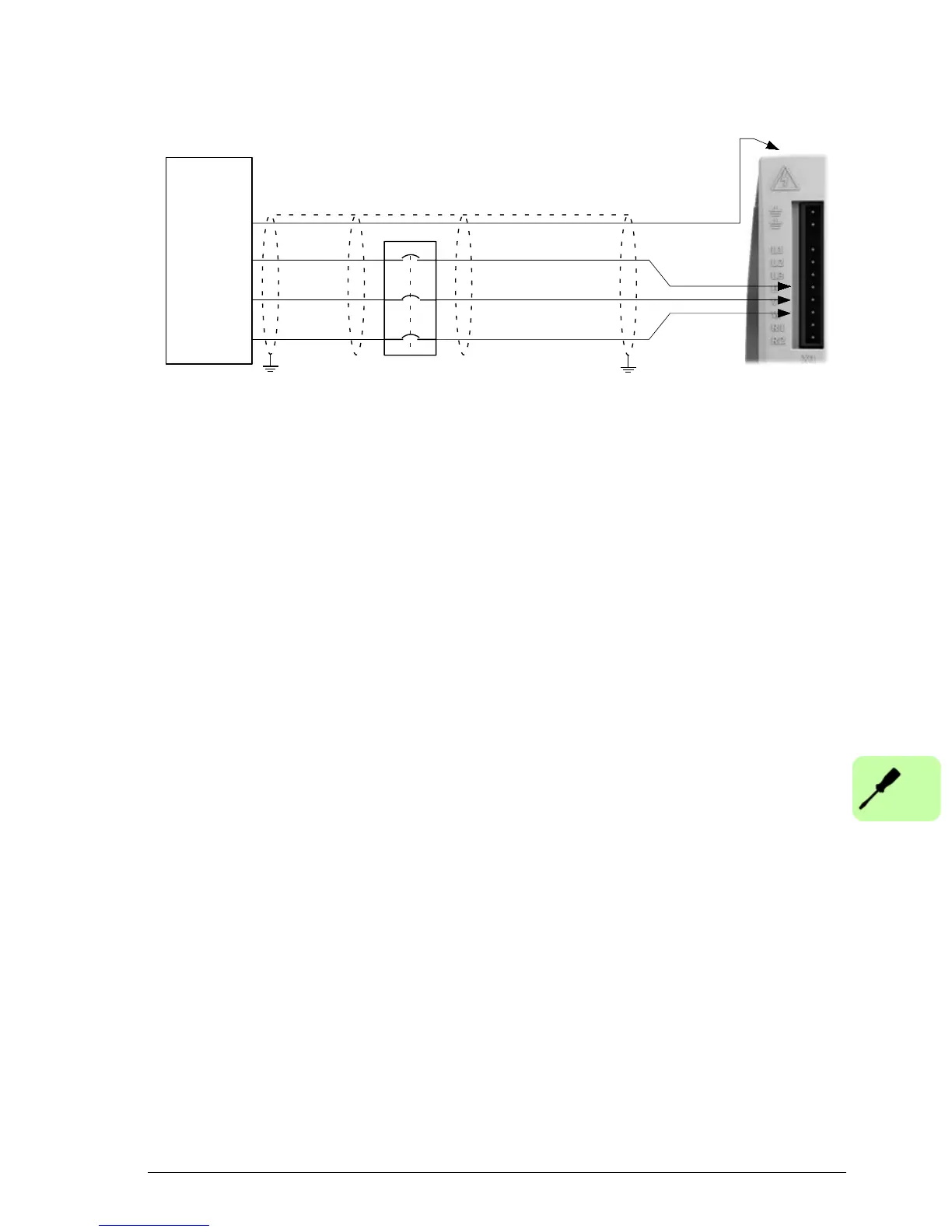

It is essential that the motor cable shield is correctly bonded to a functional earth,

typically the same earthed metal backplane on which the MicroFlex e150 is mounted.

The motor power output cable carries a high frequency high current waveform to the

motor, so the cable’s shielding must be earthed to prevent the cable radiating

electromagnetic contamination into the surrounding area. Such contamination can

cause spurious errors in unrelated parts of the installation, such as low voltage

communication cables. To provide a low impedance path to earth and effective

shielding, the conductor must provide contact with a large proportion of the cable’s

circumference. The following diagram shows two possible methods.

Exposing the cable shield

1. Make a single circular cut in the cable’s outer sheath, ensuring that the cable’s

braided shield is not damaged.

2. Slide the section of outer sheath towards the end of the cable to expose an area

of braided shield. Carefully remove the excess sheath at the end of the cable.

3. Attach the metal P-clip or clamp to the exposed area of braided shield.

4. Ensure that the P-clip (or Motor Cable Management Bracket, OPT-CM-001) is

securely attached to an unpainted area of the metal backplane.

Motor

Earth

Connect motor

earth/ground

to protective

earth on top of

drive.

Unshielded

lengths should

be as short as

possible.

To earth/ground outer

shield, use 360° clamp

connected to backplane.

Optional motor

circuit contactors.

Loading...

Loading...