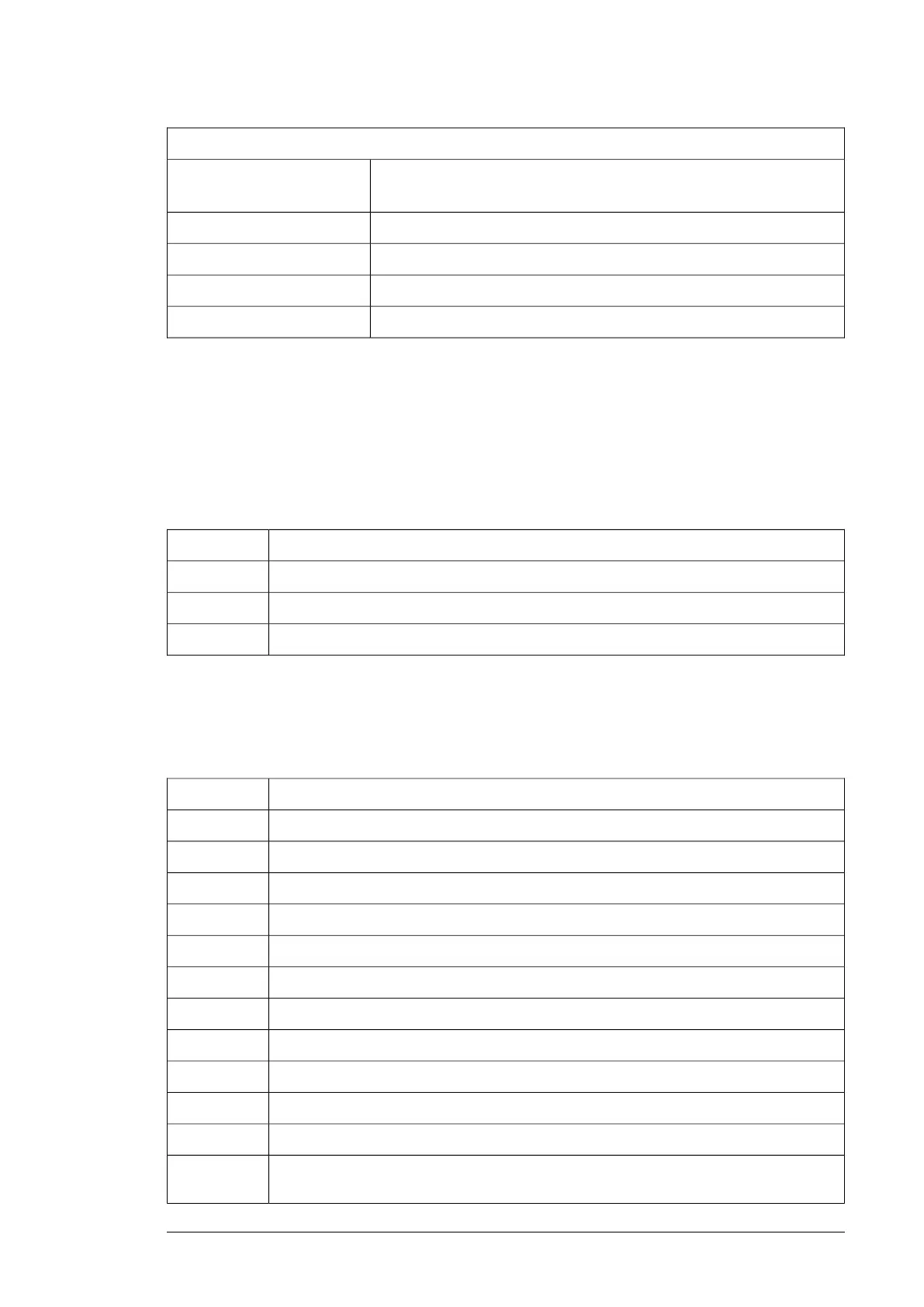

Threaded inserts

Torque in N.m

(steel/ stainless steel)

Bolt and nuts

7.9M5

12M6

20M8

34M10

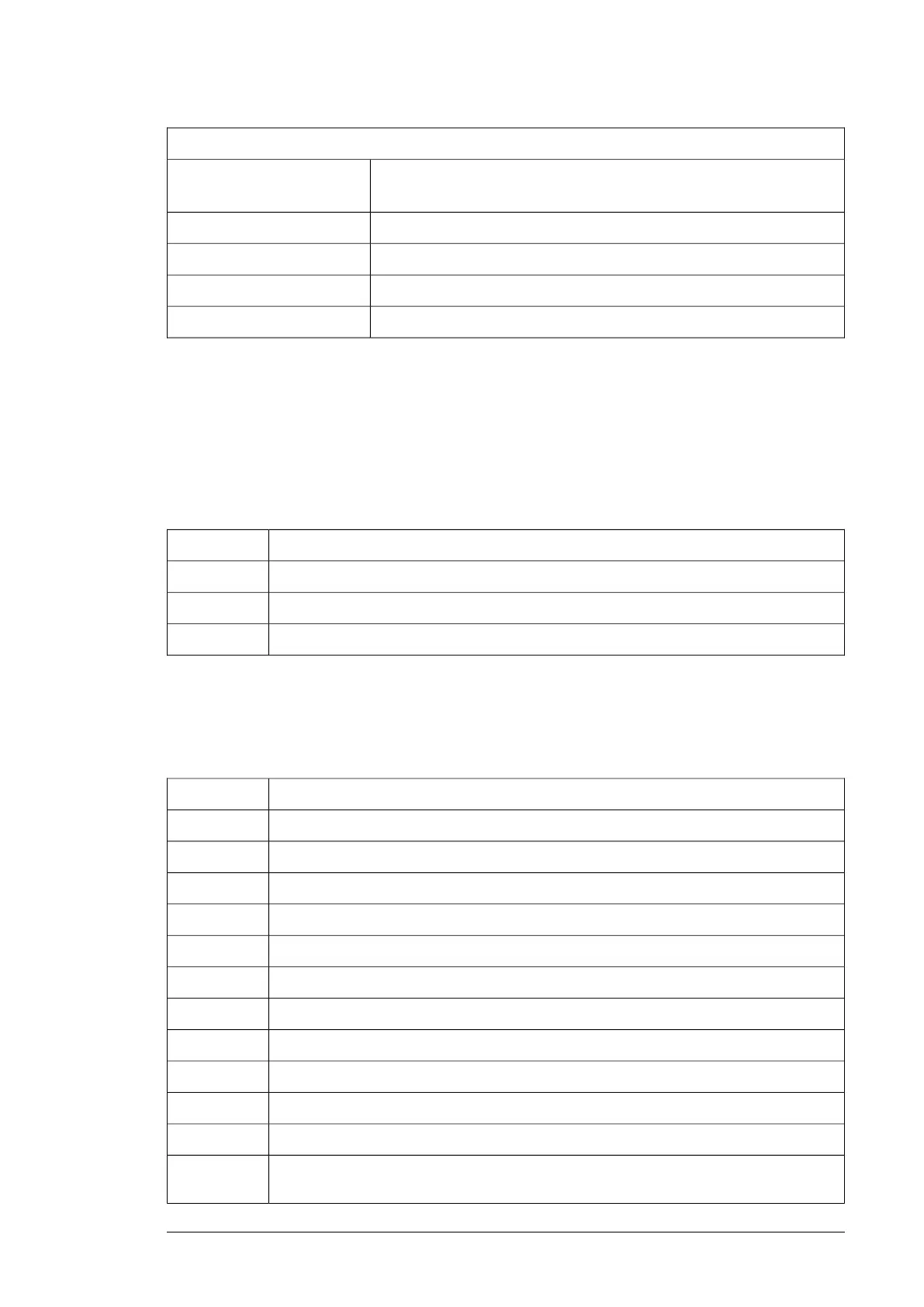

Maintenance intervals

The maintenance and component replacement intervals are based on the specified

operational and environmental conditions.

ABB establishes the following as a minimum maintenance schedule. The MVCS final

maintenance schedule must be adapted and defined by the maintenance responsible of

the plant according to the site conditions, operations and others.

DescriptionAction

Visually inspect and perform maintenance if it is necessary.I

On-site/off-site performance work (commissioning, tests, measurements, etc.)P

Replace the component.R

For more information on maintenance, contact your local ABB service representative.

■ Maintenance activities

Perform the following inspections at least once in every six months.

TaskAction

Check the operating environment, surroundings and conditions.I

Check the availability of spare parts.I

Check for any dust, corrosion, etc. inside and outside the MVCS.I

Check and clean the inlet and outlet grills & filters.I

Check the sealing of all cable entries to ensure that the IP protection level is maintained.I

Clean the filters of the air inlet and outlet.I

Examine the tightness and cleanliness of the main circuit terminals and earth connections.I

Inspect the general conditions of the MVCS (door sealing, cooling fan operation, etc.)I

Inspect the operation of locks, hinges, and gaskets.I

Check that all labels are readable and in proper conditions.I

Examine the condition of the foundation.I

Check the maintenance activities of each component in its respective user manual (MV

Transformer, MV Switchgear, AASS Transformer etc) .

I

Maintenance 55

Loading...

Loading...