3

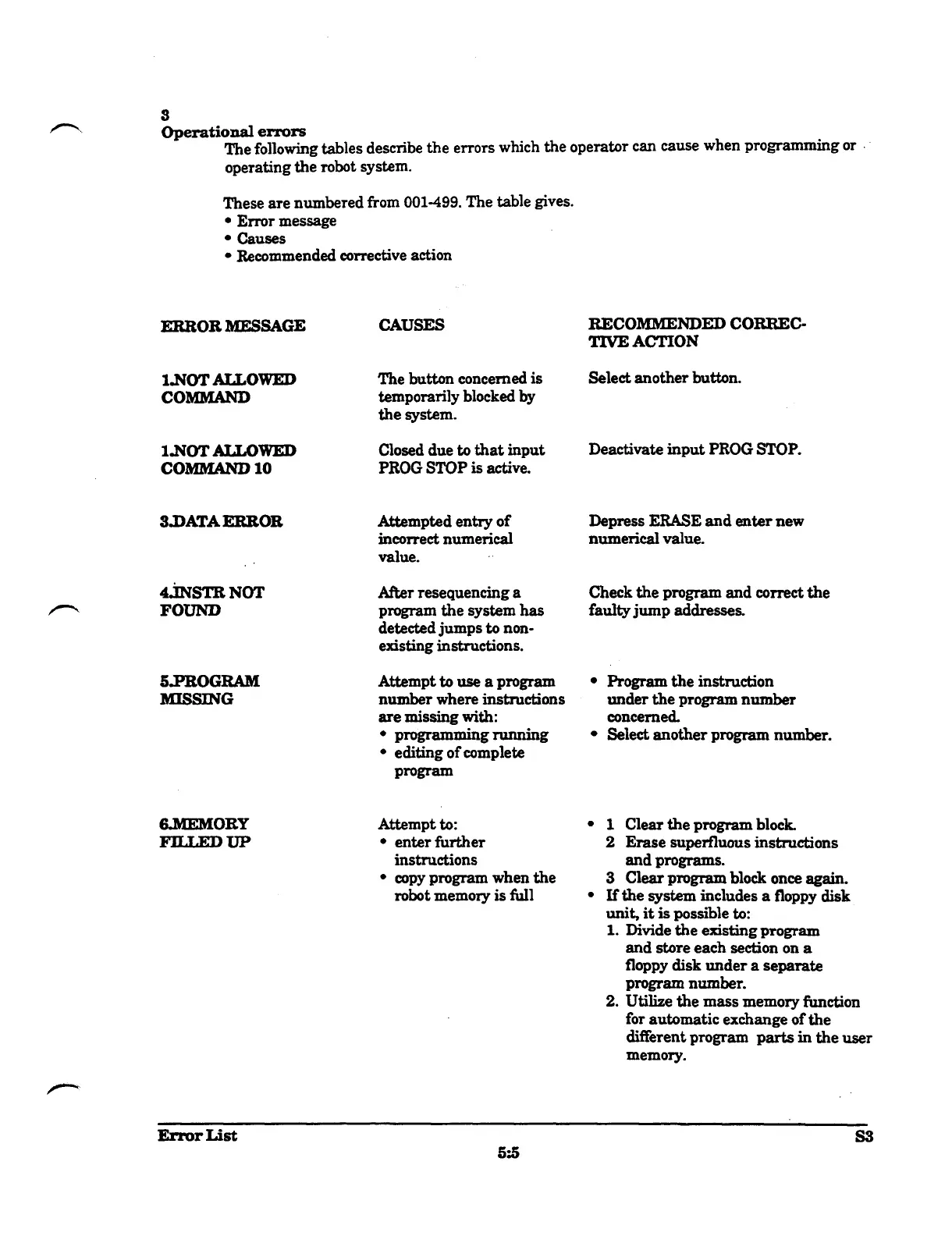

Operational errors

The following tables describe the errors which the operator can cause when programming or

operating the robot system

.

These are numbered from 001-499

. The table gives

.

•

~

Error message

•

~

Causes

•

~

Recommended corrective action

3 DATA ERROR

4JNSTR NOT

FOUND

S

.PROGRAM

MUSSING

6

.MEMORY

FILLED UP

Error List

ERROR MESSAGE

1

.NOT ALLOWED

COMMAND

1

.NOT ALLOWED

COMMAND 10

CAUSES

The button concerned is

temporarily blocked by

the system

.

Closed due to that input

PROG STOP is active

.

Attempted entry of

incorrect numerical

value

.

After resequencing a

program the system has

detected jumps to non-

existing instructions

.

Attempt to use a program

number where instructions

are missing with

:

•

~

programming running

•

~

editing of complete

program

Attempt to

:

•

~

enter further

instructions

•

~

copy program when the

robot memory is full

5

:5

RECOMMENDED CORREC-

TIVE ACTION

Select another button

.

Deactivate input PROG STOP

.

Depress ERASE and enter new

numerical value

.

Check the program and correct the

faulty jump addresses

.

•

~

Program the instruction

under the program number

concerned

.

•

~

Select another program number

.

•

~

1 Clear the program block

.

2 Erase superfluous instructions

and programs

.

3 Clear program block once again

.

•

~

If the system includes a floppy disk

unit, it is possible to

:

1

. Divide the existing program

and store each section on a

floppy disk under a separate

program number

.

2

. Utilize the mass memory function

for automatic exchange of the

different program parts in the user

memory

.

S3

Loading...

Loading...