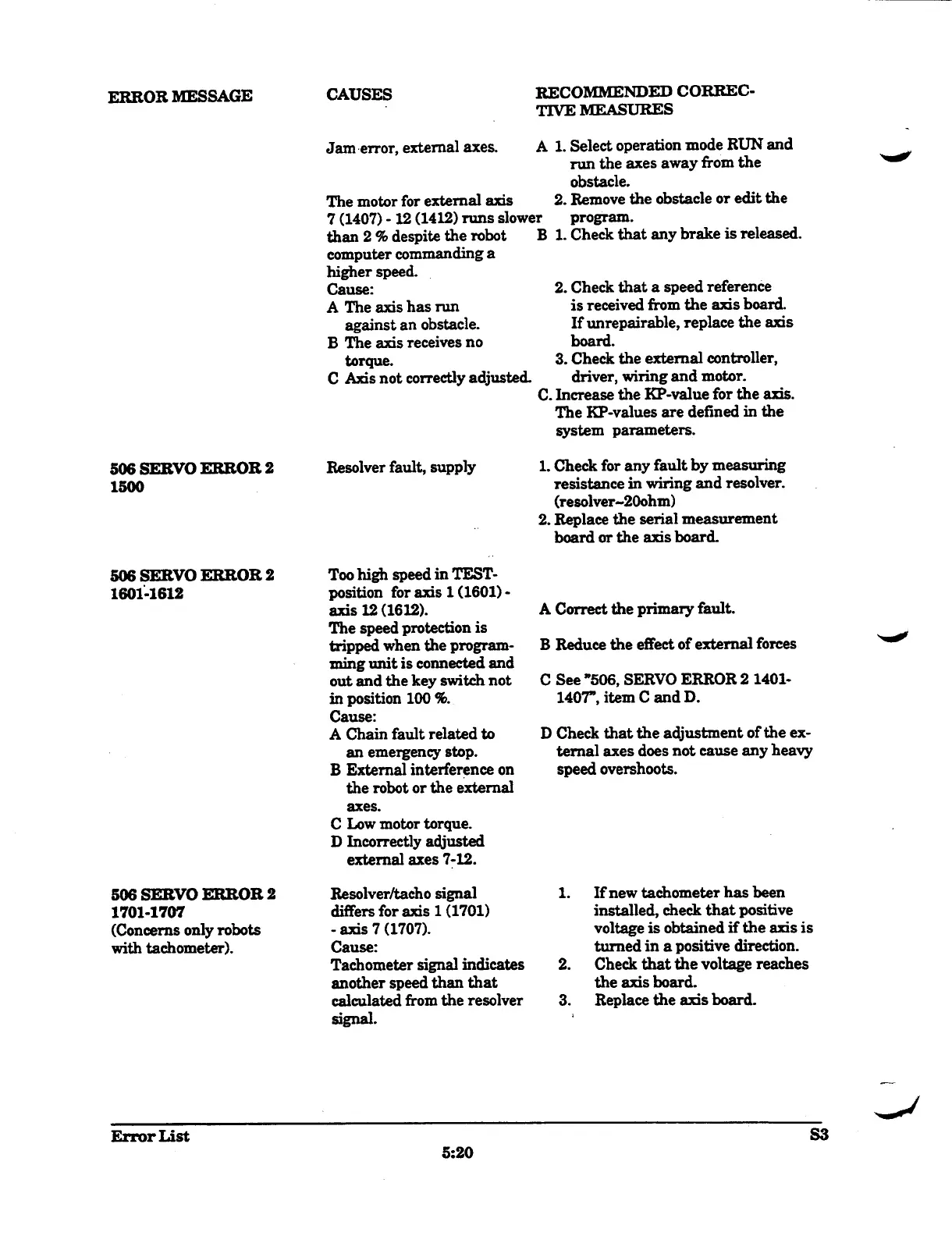

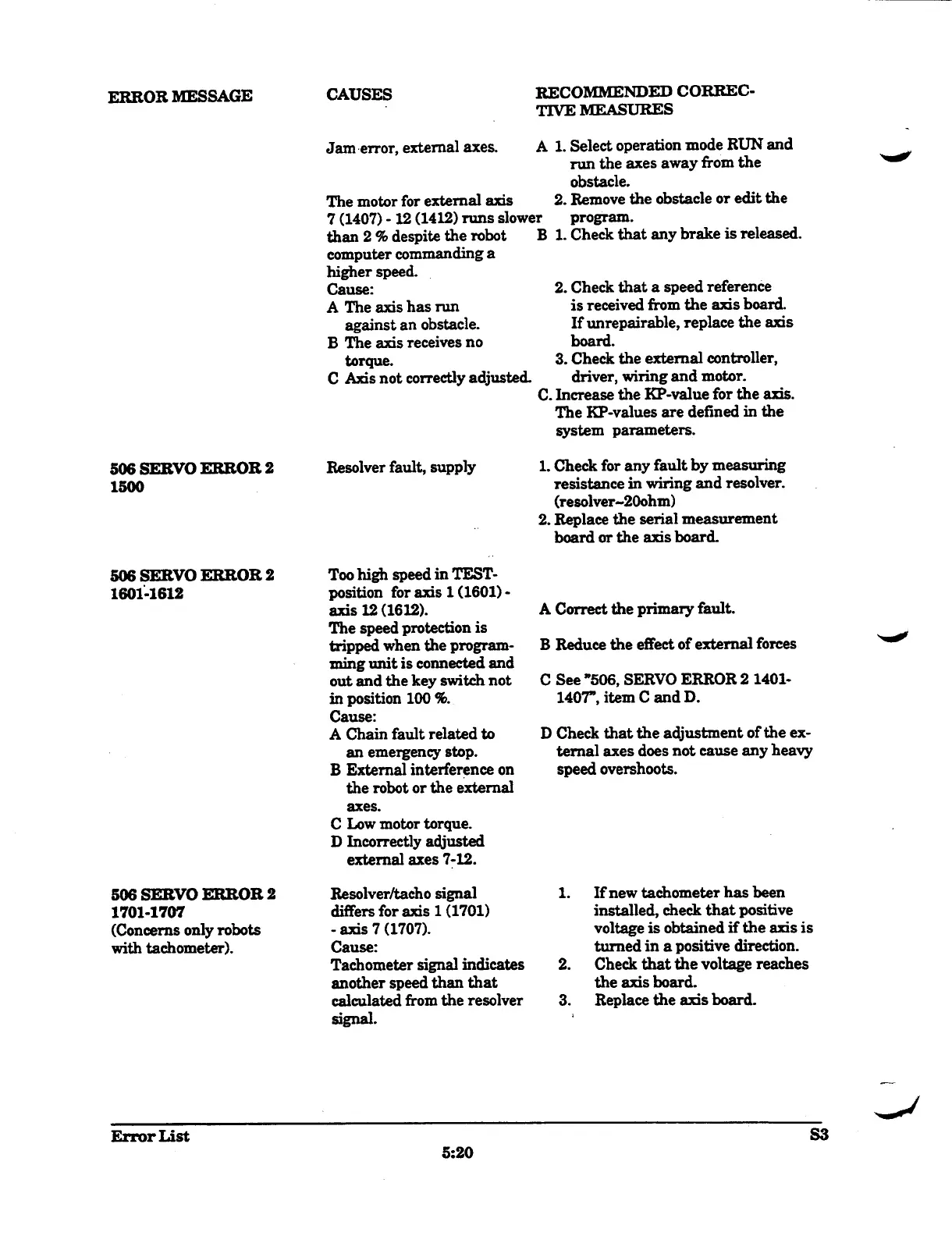

ERROR MESSAGE

~

CAUSES

~

RECOMMENDED CORREC-

TIVE MEASURES

506 SERVO ERROR 2

~

Too high speed in TEST-

1601-1612

~

position for axis 1(1601)

-

axis 12 (1612)

.

The speed protection is

tripped when the program-

ming unit is connected and

out and the key switch not

in position 100'%

.

Cause

:

A Chain fault related to

an emergency stop

.

B External interference on

the robot or the external

axes

.

C Low motor torque

.

D Incorrectly adjusted

external axes 7-12

.

506

SERVO ERROR

2

~

Resolver/tacho signal

1701-1707

~

differs for axis 1 (1701)

(Concerns only robots

~

- axis 7 (1707)

.

with tachometer)

.

~

Cause

:

Tachometer signal indicates

another speed than that

calculated from the resolver

signal

.

Error List

Jam error, external axes

.

B

C

5

:

2

0

A 1

. Select operation mode RUN and

run the axes away from the

obstacle

.

2

. Remove the obstacle or edit the

program

.

1

. Check that any brake is released

.

The motor for external axis

7 (1407)

-

12 (1412) runs slower

than 2 % despite the robot

~

B

computer commanding a

higher speed

.

Cause

:

~

2

. Check that a speed reference

A The axis has run

~

is received from the axis board

against an obstacle

.

~

If unrepairable, replace the axis

The axis receives no

~

board

.

torque

.

~

3

. Check the external controller,

Axis not correctly adjusted

~

driver, wiring and motor

.

C

. Increase the EP-value for the axis

.

The KP-values are defined in the

system parameters

.

506

SERVO ERROR

2

~

Resolver fault, supply

~

1

. Check for any fault by measuring

1500

~

resistance in wiring and resolver

.

(resolver-20ohm)

2

. Replace the serial measurement

board or the axis board

.

A Correct the primary fault

.

B Reduce the effect of external forces

C See '506, SERVO ERROR 21401-

1407", item C and D

.

D Check that the adjustment of the ex-

ternal axes does not cause any heavy

speed overshoots

.

1

.

If new tachometer has been

installed, check that positive

voltage is obtained if the axis is

turned in a positive direction

.

2

.

Check that the voltage reaches

the axis board

.

3

.

Replace the axis board

.

S3

Loading...

Loading...