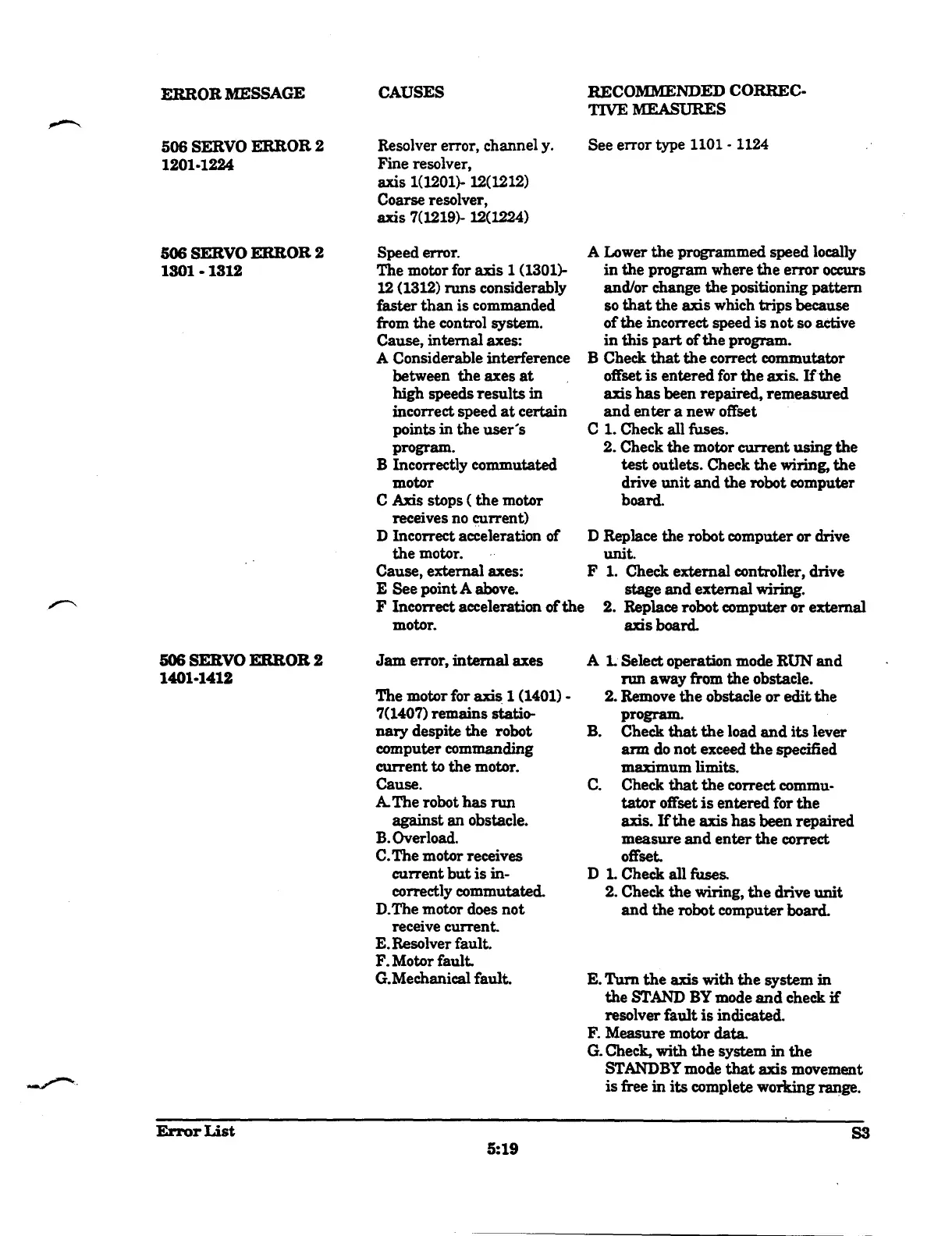

ERROR MESSAGE

~

CAUSES

506 SERVO ERROR 2

~

Resolver error, channel y

.

1201

.1224

~

Fine resolver,

axis 1(1201)- 12(1212)

Coarse resolver,

axis 7(1219)- 12(1224)

506 SERVO ERROR 2

1301-1312

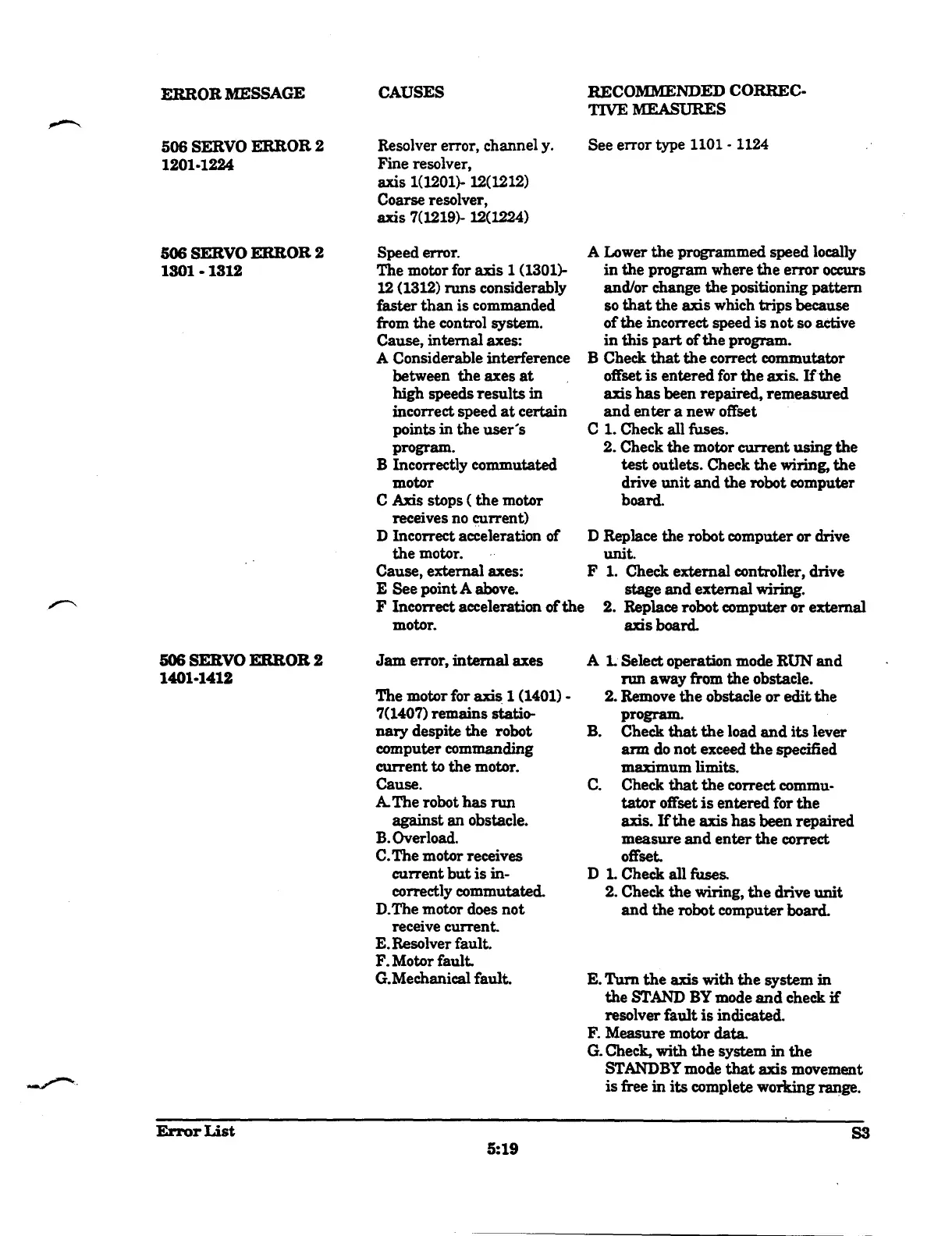

506 SERVO ERROR 2

~

Jam error, internal axes

1401-1412

The motor for axis 1 (1401)

-

7(1407) remains statio-

nary despite the robot

computer commanding

current to the motor

.

Cause

.

A- The robot has run

against an obstacle

.

B

. Overload

.

C

. The motor receives

current but is in-

correctly commutated

.

D

.The motor does not

receive current

.

E

. Resolver fault

.

F

. Motor fault

.

G

.Mechanical fault

.

Error List

Speed error

.

The motor for axis 1(1301)-

12 (1312) runs considerably

faster than is commanded

from the control system

.

Cause, internal axes

:

A Considerable interference

between the axes at

high speeds results in

incorrect speed at certain

points in the user's

program-

•

~

Incorrectly commutated

motor

C Axis stops

(

the motor

receives no current)

D Incorrect acceleration of

the motor

.

Cause, external axes

:

•

~

See point A above

.

F Incorrect acceleration of the

2

. Replace robot computer or external

motor

.

~

axis board

.

5

:

1

9

RECOMMENDED CORREC-

TIVE MEASURES

See error type 1101 -

1124

A Lower the programmed speed locally

in the program where the error occurs

and/or change the positioning pattern

so that the axis which trips because

of the incorrect speed is not so active

in this part of the program

.

•

~

Check that the correct commutator

offset is entered for the axis

. If the

axis has been repaired, remeasured

and enter a new offset

C 1

. Check all fuses

.

2

. Check the motor current using the

test outlets

. Check the wiring, the

drive unit and the robot computer

board

.

D Replace the robot computer or drive

unit

.

F 1

. Check external controller, drive

stage and external wiring

.

A 1 Select operation mode RUN and

run away from the obstacle

.

2

. Remove the obstacle or edit the

program

.

B

.

Check that the load and its lever

arm do not exceed the specified

maximum limits

.

C

. Check that the correct commu-

tator offset is entered for the

axis . If the axis has been repaired

measure and enter the correct

offset

.

•

~

1

. Check all fuses

.

2

. Check the wiring, the drive unit

and the robot computer board

.

E

. Turn the axis with the system in

the STAND BY mode and check if

resolver fault is indicated

.

•

~

Measure motor data

.

•

~

Check, with the system in the

STANDBY mode that axis movement

is free in its complete working range

.

S3

Loading...

Loading...